Wheel holding mechanism of rodless aircraft tractor

A technology of aircraft tractor and wheel holding mechanism, which is applied to aircraft parts, ground equipment, transportation and packaging, etc. It can solve the problem of not being able to clamp aircraft nose wheels of different diameters, not having automatic matching wheel size, airports and civil aviation The company's economic loss and other issues can avoid easy up and down jumps, reduce use risks, and enhance safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

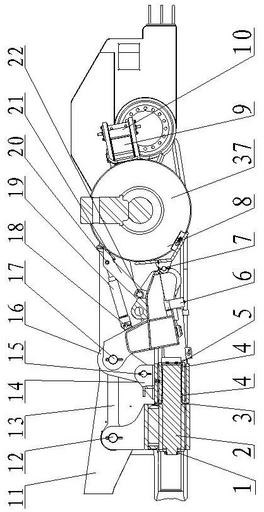

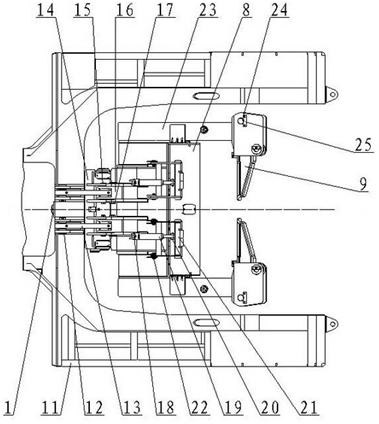

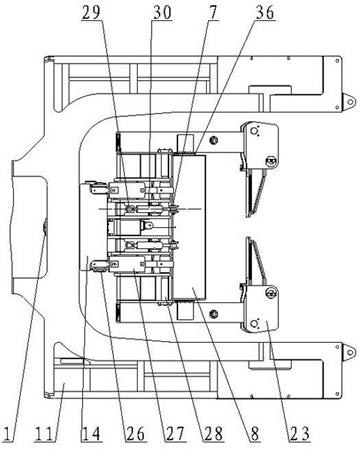

[0024] Below in conjunction with accompanying drawing, the utility model is further described:

[0025]As shown in the drawings, a wheel holding mechanism of a rodless aircraft tractor includes a vehicle frame 11, a main lift link 16, an auxiliary lift link 13, a lift cylinder 27, a swing main shaft 2, and a swing support 14. , compression bracket 21, compression oil cylinder 19, support platform 23 and clamping device, frame 11 center is provided with swing main shaft 2, front end of swing main shaft 2 is equipped with lock nut 1, and rear end passes positioning pad 3, axle sleeve 4. It is connected with the swing bracket 14. A support platform 23 is provided on one side of the swing bracket 14. Support arms 41 are respectively provided at both ends of the support platform 23. A compression cylinder 19 and a compression bracket 21 are provided on the top, and a lifting cylinder is provided on the bottom. 27 and the pushing device, one end of the lifting cylinder 27 is hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com