Composite wallboard and combined wallboard

A composite wallboard and panel technology, applied in the direction of walls, building components, buildings, etc., to achieve the effect of reducing decoration links, beautiful appearance, and saving construction funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

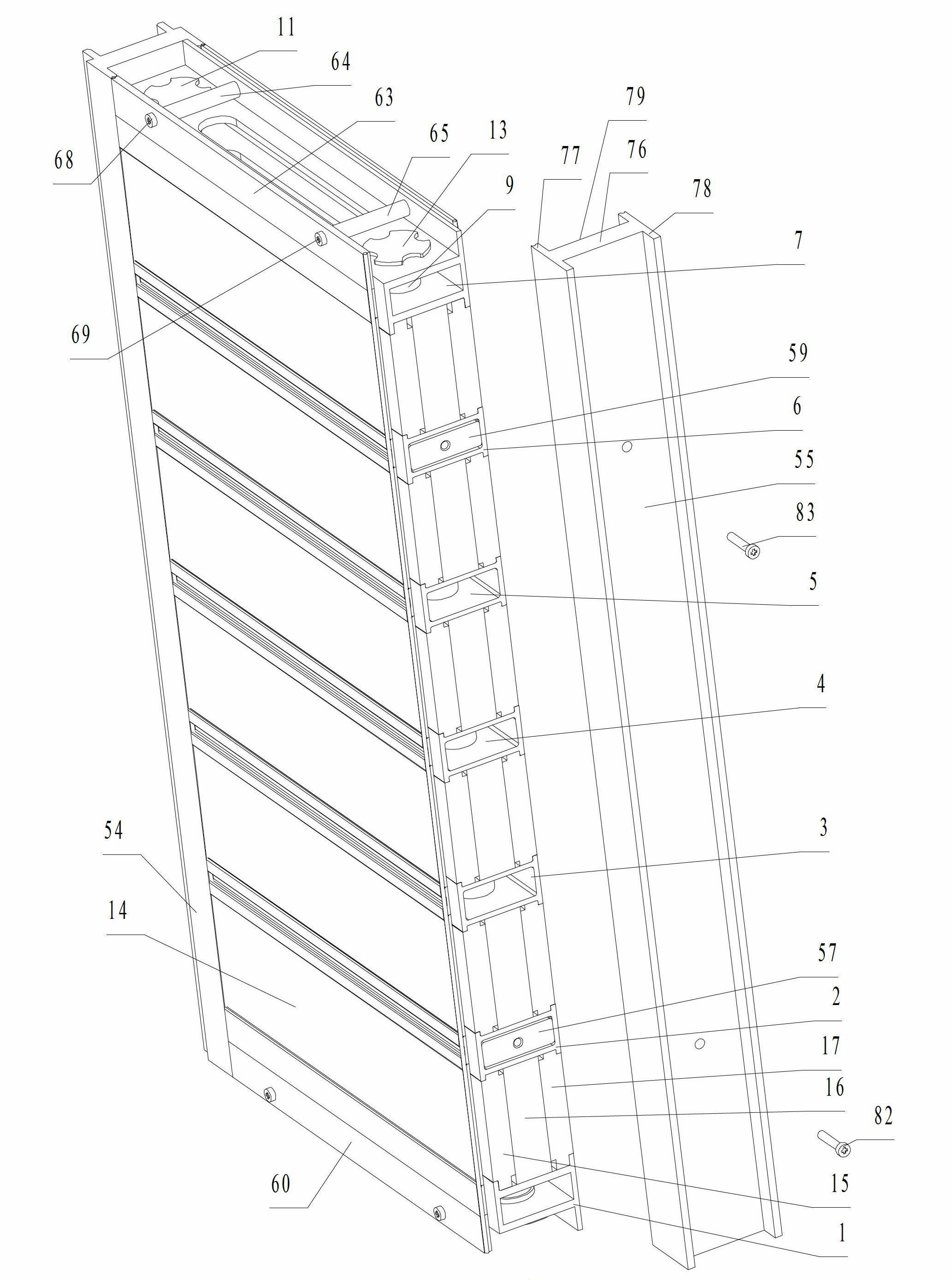

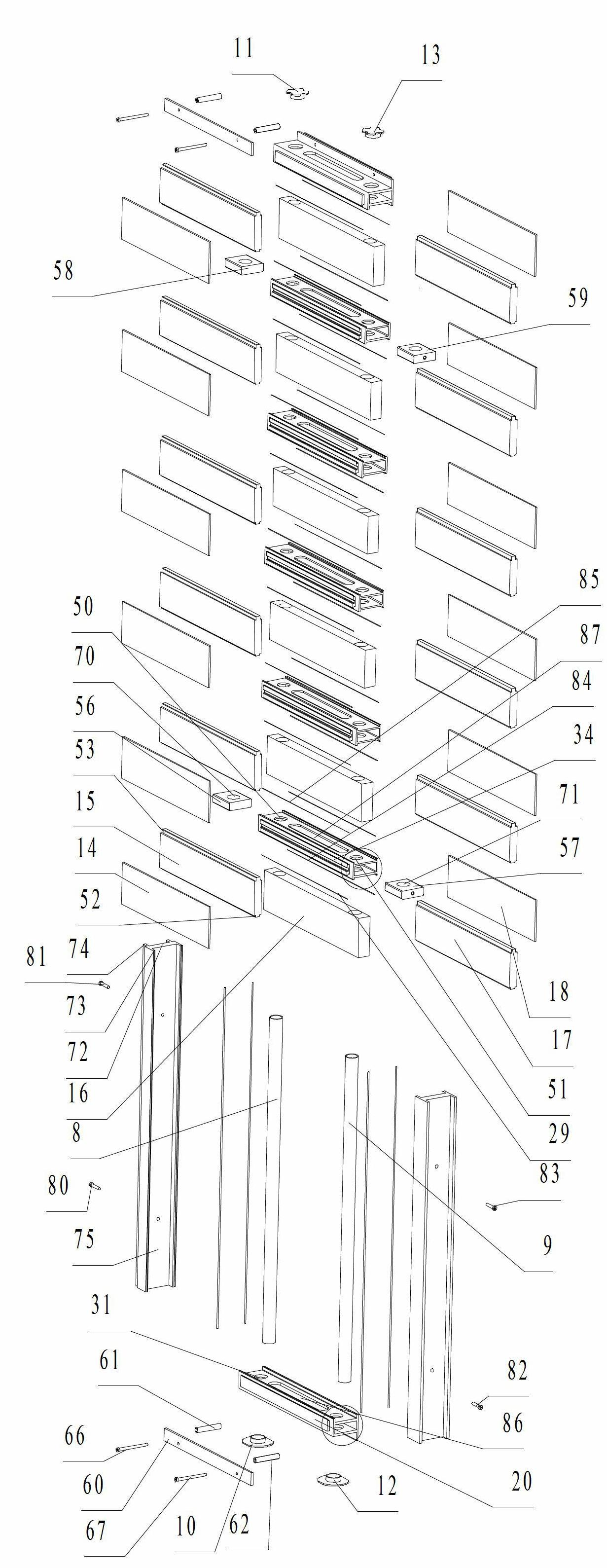

[0059] Such as figure 1 , figure 2 As shown, a composite wall panel, including horizontally installed from bottom to top, parallel lower keel 1, middle keel 2, middle keel 3, middle keel 4, middle keel 5, middle keel 6, upper keel 7, fixed Shaft 8, fixed shaft 9, locking parts 10 and 11 installed at both ends of the fixed shaft 8, locking parts 12 and 13 installed at both ends of the fixed shaft 9, installed between the lower keel 1 and the middle keel 2 Between, or between the middle keel 2 and the middle keel 3, or between the middle keel 3 and the middle keel 4, or between the middle keel 4 and the middle keel 5, or between the middle keel 5 and the middle keel 6, or between the middle keel 6 Panel 14, dividing plate 15, dividing plate 16, dividing plate 17, panel 18 installed sequentially from front to back between upper keel 7.

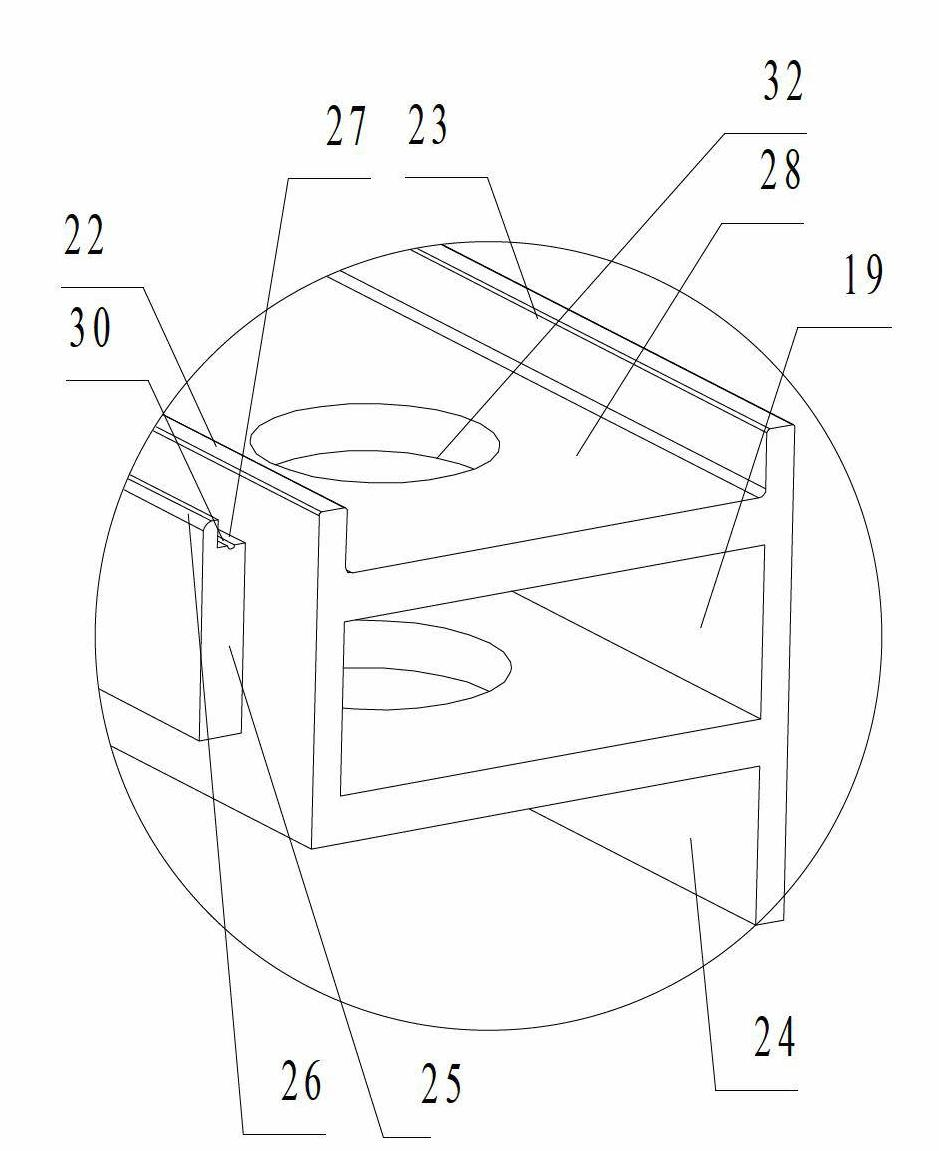

[0060] Such as figure 2 , image 3 As shown, the lower keel 1 is a profile, including a square tube-shaped keel body 19, a first positioni...

Embodiment 2

[0067] Such as Figure 5 As shown, the difference from Example 1 is that no partition is installed in the cavity formed by the adjacent keel and the panel, but the cement filling layer is poured through the elongated through hole on each keel, that is, the cement pouring hole 110 111.

Embodiment 3

[0069] Such as Image 6 As shown, the difference from Embodiment 1 is that a composite wallboard includes horizontally installed from bottom to top, parallel lower keel 120, middle keel 121, middle keel 122, middle keel 123, middle keel 124, middle keel Keel 125, middle keel 126, upper keel 127, two fixed shafts 128, locking pieces 130 installed at both ends of the fixed shaft 128, installed between the lower keel 120 and the middle keel 121, or between the middle keel 121 and the middle keel 122 , or between the middle keel 122 and the middle keel 123, or between the middle keel 123 and the middle keel 124, or between the middle keel 124 and the middle keel 125, or between the middle keel 125 and the middle keel 126, or between the middle keel 126 and the middle keel Panels 134 , partitions 135 , partitions 136 , partitions 137 , and panels (not shown) are sequentially installed between the upper keels 127 from front to back.

[0070] The lower keel 120, the middle keel 121,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com