Novel lock body of servo brake steel-plastic structure

A technology of follow-up gate and lock body, which is applied in the direction of building locks, building construction, construction, etc., and can solve the problems of falling, high manufacturing cost, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

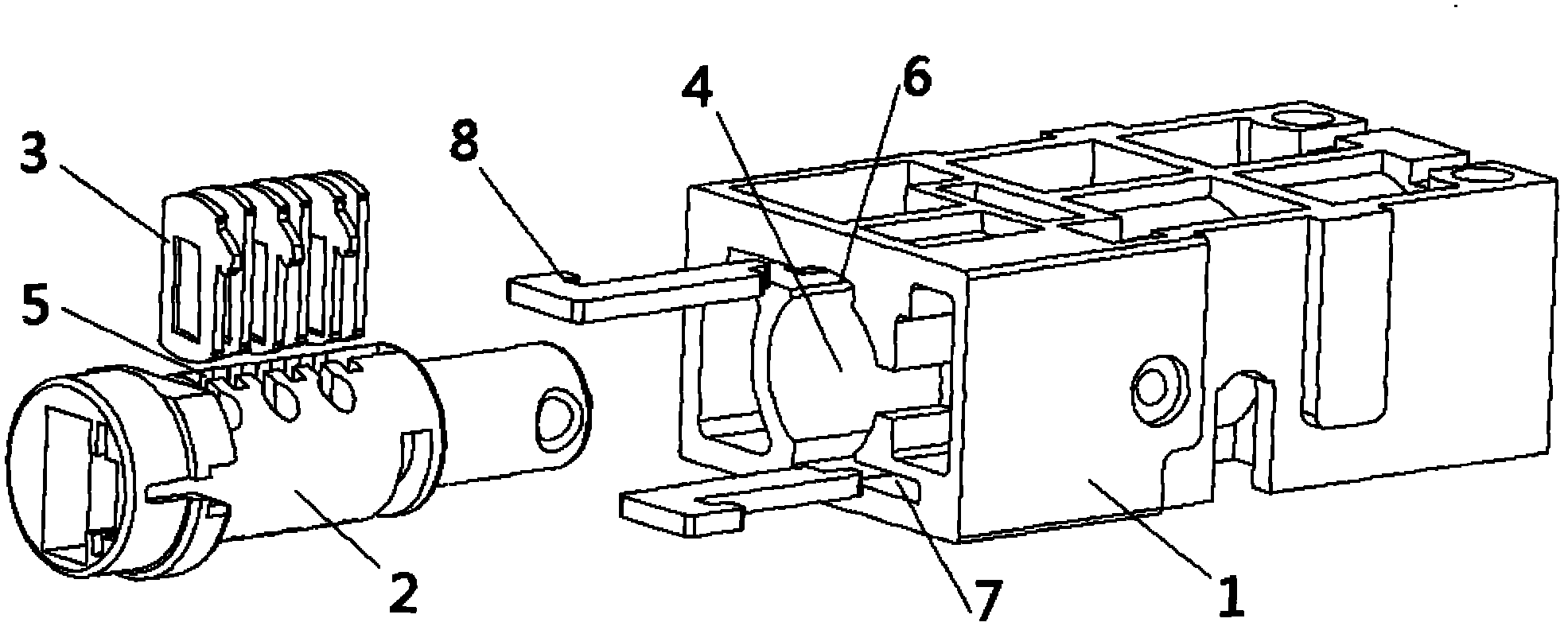

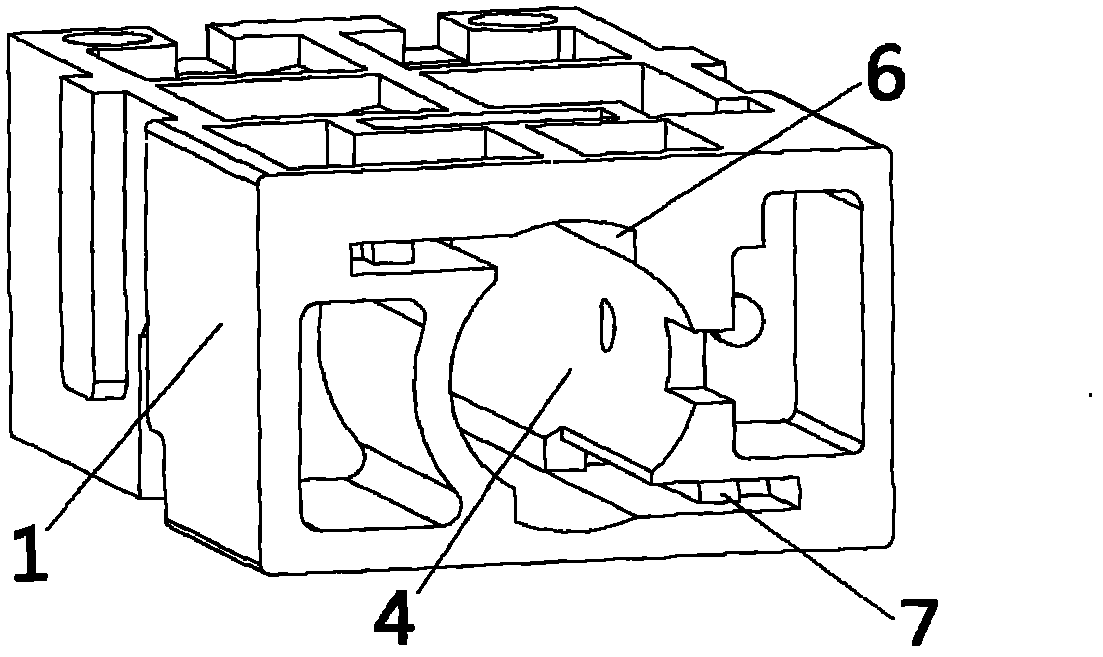

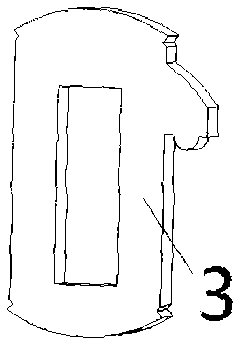

[0009] A new lock body with a steel-plastic structure for a servo brake, mainly including a lock body 1, a lock cylinder 2, and a lock piece 3. The lock body 1 has a lock cylinder hole 4, the lock cylinder 2 is placed in the lock cylinder hole 4, and the lock cylinder 2 is provided with a lock plate hole 5, and the lock plate 3 is placed in the lock plate hole 5 on the lock core 2. The lock body 1 and the lock plate 3 return position on the lock core 2 have a lock plate return hole 6. One end of the return hole 6 has a locking block hole 7, the locking block 8 is 7-shaped, matches the locking block hole 7, the locking block 8 is placed in the locking block hole 7, and the locking block 8 is locked. The lock core is composed of lock plate 3 and locking block 8 so that the lock core does not rotate to achieve the locking function. The lock body of the present invention uses engineering plastics instead of metal, and there are lock core 2, lock plate 3 and return hole on the lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com