Novel multifunctional exposed-corner lockset for wall templates

A multi-functional, formwork technology, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problems of difficult processing, poor construction quality, Hollow cracking and other problems, to achieve the effect of saving wood resources, high self-strength, and easy to knock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

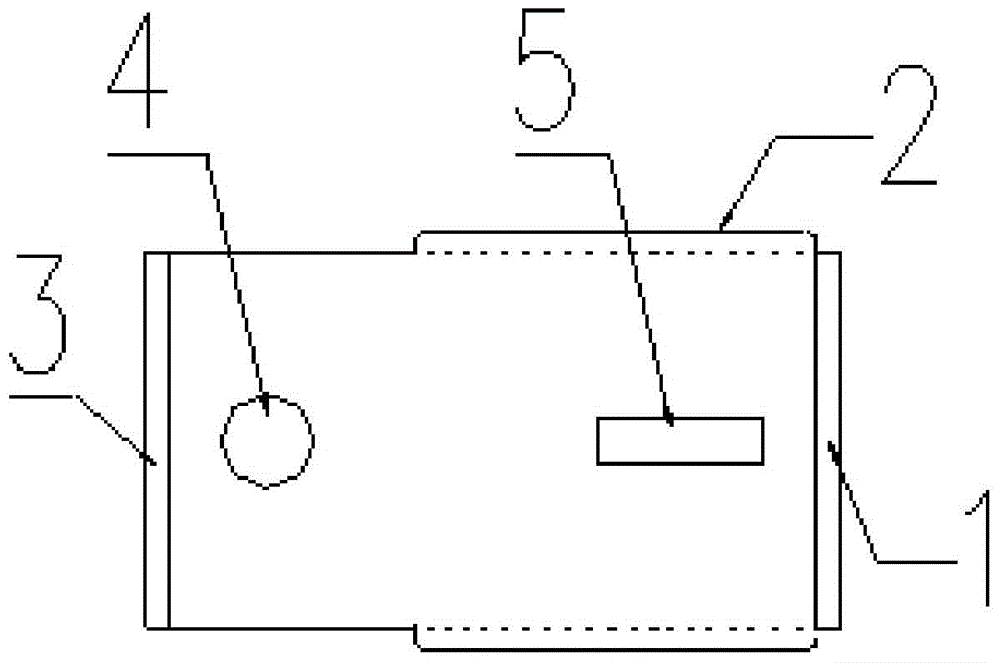

[0023] Such as Figure 1-Figure 9 As shown, the present invention provides a new type of male corner multifunctional lock for wall formwork, which includes a lock body, a mounting pin and a locking pin 8 . Among them, the main body of the lockset, the installation pin and the lock pin are all made of steel shaped materials.

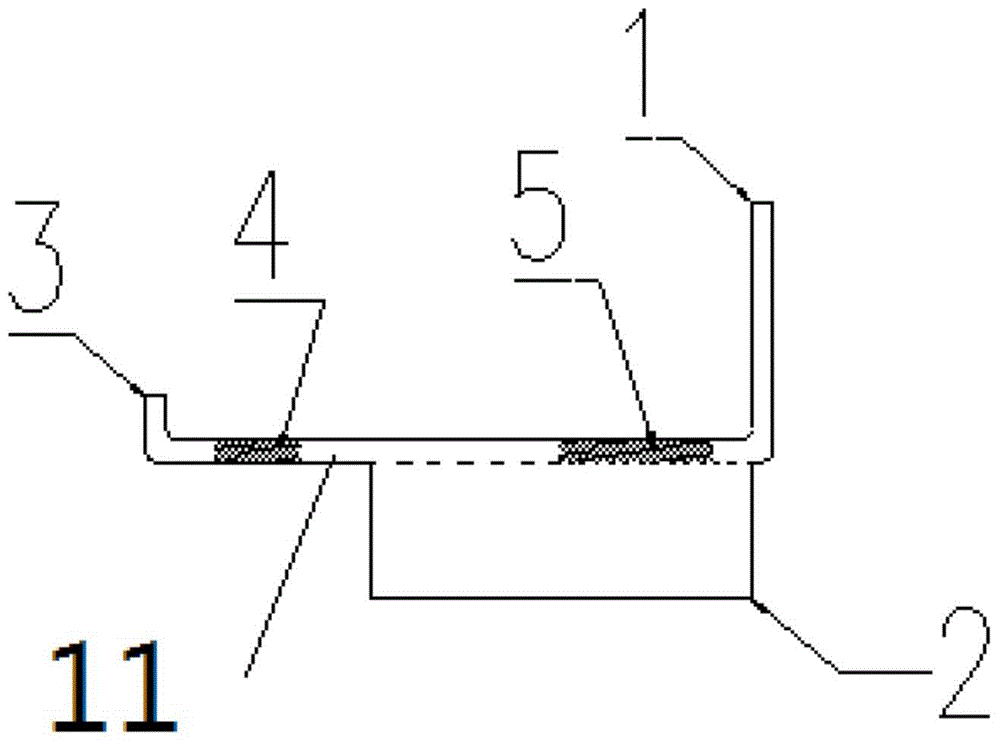

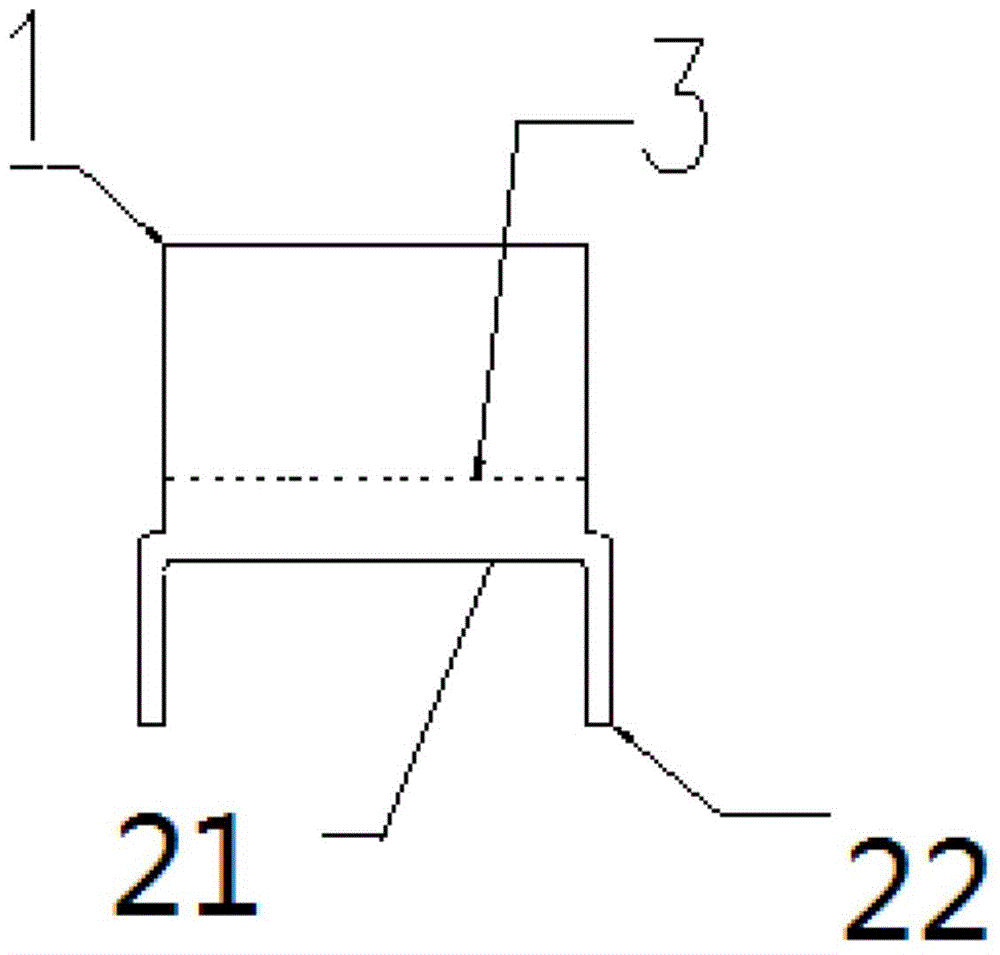

[0024] The lock body includes a U-shaped lock sleeve 2 composed of a bottom plate 21 and side walls 22 on both sides. The U-shaped lock sleeve 2 is used to clamp the first main back flute 10 . One of the sides of the base plate 21 of the U-shaped lock sleeve 2 is provided with a first baffle plate 1 perpendicular to the base plate 21, and the other opposite side is provided with a base plate extension plate 11, and the end of the base plate extension plate 11 is perpendicular to the base plate 21. Two baffles 3 , the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com