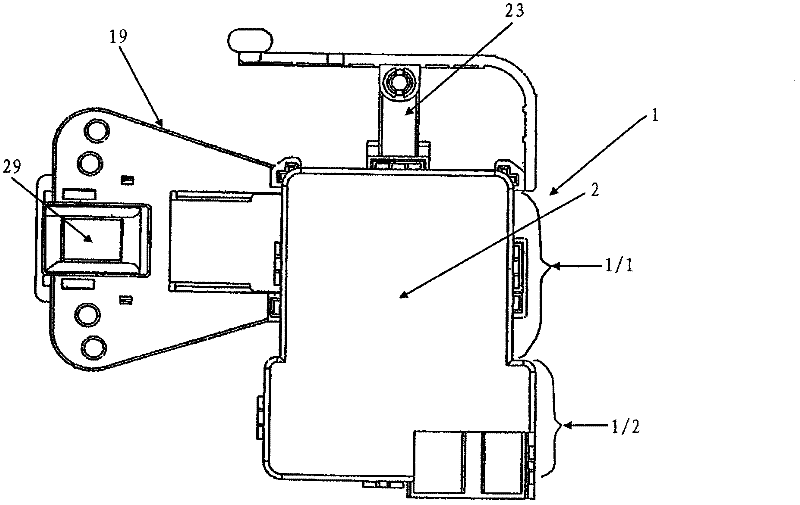

Electromagnetic door lock of electrical equipment

A technology for electromagnetic door locks and electrical equipment, applied in non-mechanical transmission-operated locks, building locks, buildings, etc., can solve the problems of high material cost and assembly cost, abnormal state of electromagnetic door locks, affecting the final use of products, etc. Reliable operation, reduced parts count, and high availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

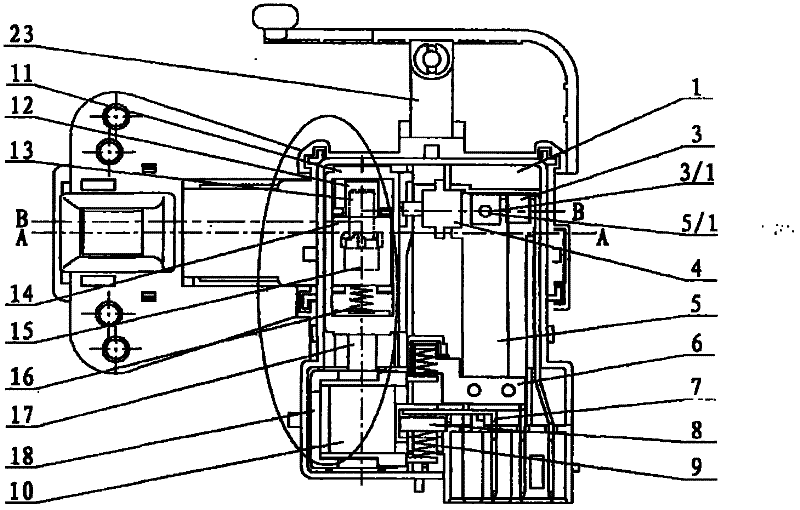

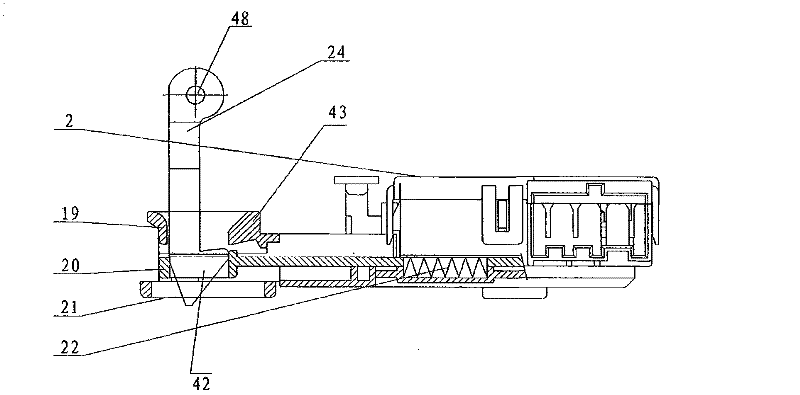

[0122] The working process of the first embodiment is as follows:

[0123] During normal operation, the door of the electrical equipment is closed, and the door hook 24 pushes the slide block 20 (ie 20A) to the locked position, the lock hole of the slide block 20 (ie 20A) is aligned with the lock block 4 (ie 4A), and the lock block 4 (ie 4A) can freely enter and exit the lock hole 30; when the door lock receives the drive signal, the electromagnetic coil 10 drives the iron core 17, and drags the refill lock frame 11 (ie 11A) to the position of the lock, where the refill lock frame 11 ( That is 11A) is separated from the lock block 4 (ie 4A), and the switch shrapnel 5 drives the lock block 4 (ie) 4A to move downward due to its own elastic force, the switch is closed, and the electrical equipment can work normally; at the same time, the lock block 4 (ie 4A) enters It is fixed in the lock hole 30 of the slide block 20 (ie 20A), the slide block 20 (ie 20A) also locks the door hook...

no. 2 example

[0129] The working process of the second embodiment is as follows:

[0130] During normal operation, such as Figure 13B As shown, the electrical equipment door is closed, and the door hook 24 pushes the slide block 20 (i.e. 20B) to the locked position, and its lock hole 30 is aligned with the lock block 4 (i.e. 4B), and the lock block 4 (i.e. 4B) can come in and out freely; The door lock receives the driving signal, the electromagnetic coil 10 drives the iron core 17, drags the refill lock frame 11 (ie 11B) to the lock position, and at the same time the lock block 4 (ie 4B) moves downward along the guide groove 28, and the switch shrapnel 5 also moves downwards, the switch is closed, and the electrical equipment can work normally; meanwhile, the lock block 4 (i.e. 4B) is inserted into the lock hole 30 of the slide block 20 (i.e. 20B) to lock it, and the slide block 20 (i.e. 20B) also The door hook 24 is blocked, and the electrical equipment door cannot be opened. When the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com