Multi-punch pin special push pipe

A multi-punch and special-shaped technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problem of lack of pipe jacking hosts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

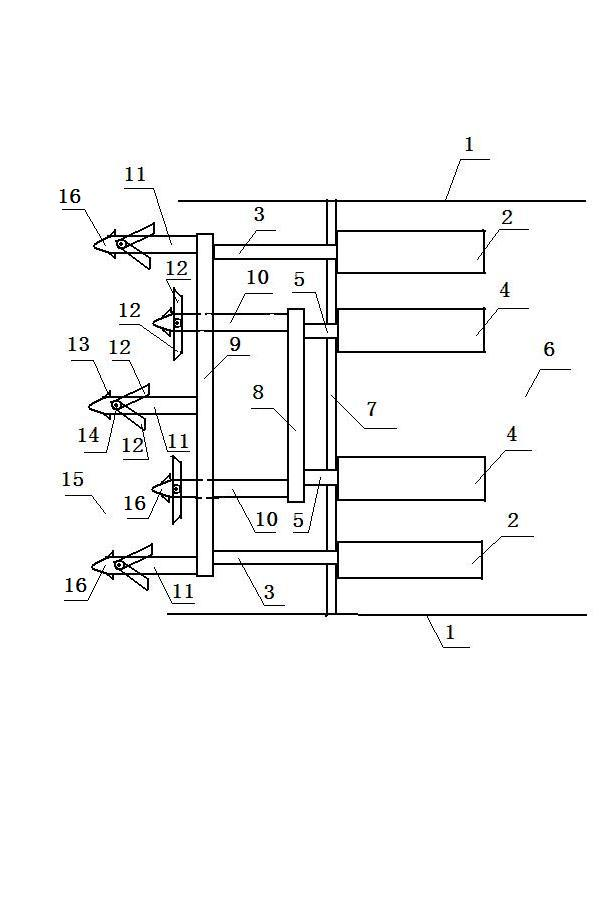

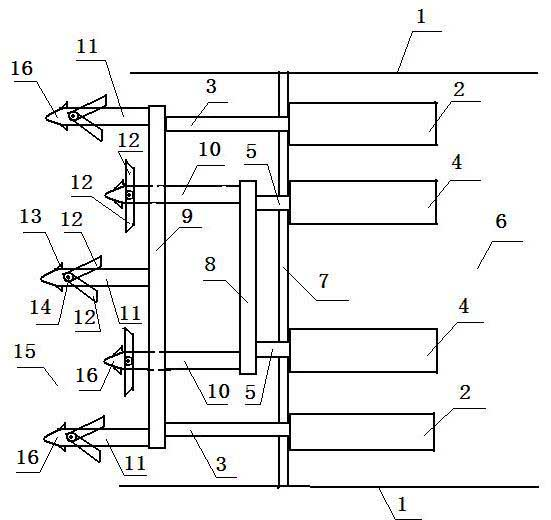

[0011] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment comprises the casing 1 of special-shaped pipe jacking, muddy water storehouse 15 on the left side, working cabin 6 on the right side, hydraulic cylinder A2, hydraulic cylinder B4 are all arranged in the working cabin, other The excavation mechanisms are all set in the mud tank, the working cabin and the mud tank are separated by the compartment plate 7, the output shaft A3 at the left end of the hydraulic cylinder A2 is connected to the connecting rod A9, and the left end of the connecting rod A is provided with a plurality of drill pipes A11, and the hydraulic cylinder The output shaft B5 at the left end of B4 is connected to the connecting rod B8, and the left end of the connecting rod B8 is provided with a plurality of drill pipes B10. Two stop blocks 13 are arranged on it, and two wing plates 12 are arranged at the right end of the stop block, and one end of the two wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com