A Split Free Piston Stirling Engine

A Stirling engine, split-type technology, which is used in hot gas variable capacity engine devices, machines/engines, mechanical equipment, etc. The effect of reducing damping, improving cycle efficiency and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

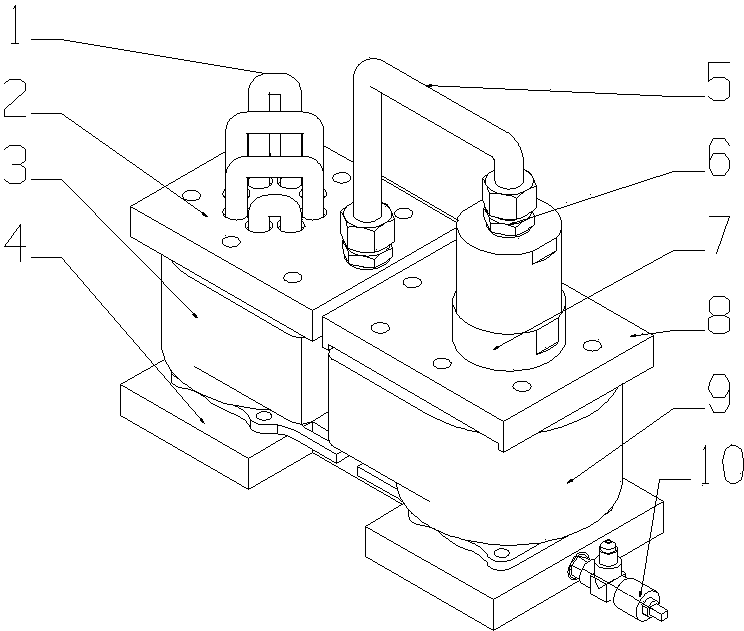

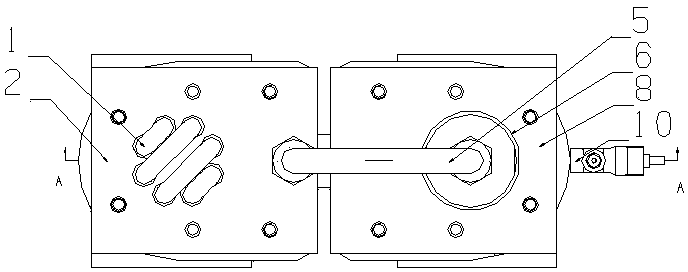

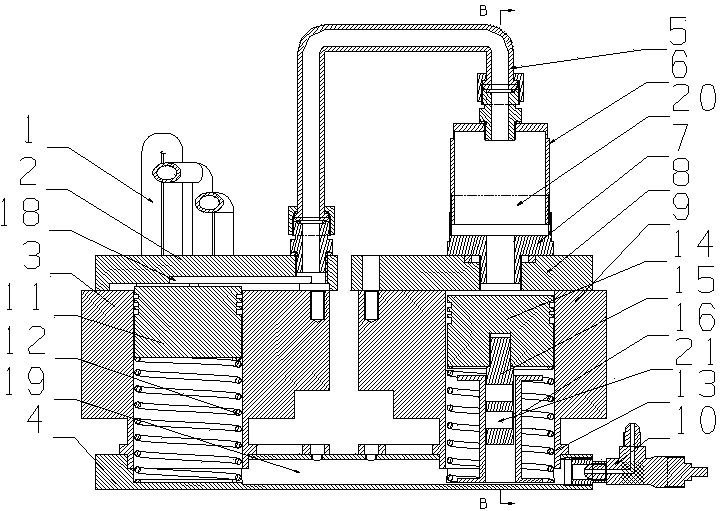

[0019] see figure 1 , figure 2 and image 3 , a split type free-piston Stirling engine comprises a hot cylinder 3 and a cold cylinder 9 mounted side by side on a base 4, a hot piston 11 is housed in the hot cylinder 3, a cold piston 14 is housed in the cold cylinder 9, a hot piston 11 and a cold cylinder The head of the piston 14 is respectively provided with three piston ring grooves. The bottom side of the cold cylinder 9 is equipped with an inflatable valve joint 10; the bottom of the hot cylinder 3 and the cold cylinder 9 are connected by a buffer chamber 19, and the top of the hot cylinder 3 is equipped with a hot chamber upper cover 2, and the top surface of the hot cylinder 3 and the hot chamber A clearance cavity 18 is provided between the bottom surfaces of the upper end cover 2, and four inverted U-shaped heating elbows 1 are installed on the upper end cover 2 of the heating chamber, and the two ends of the four inverted U-shaped heating elbows 1 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com