Hydraulic buffer

A hydraulic buffer and internal pressure technology, which is applied in the field of hydraulic buffers, can solve the problems that the buffering effect cannot be realized, and achieve the effect of prolonging the service life and reducing the amount of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The specific embodiments of the present invention are only exemplary, and can only be used to explain the present invention rather than limit the present invention.

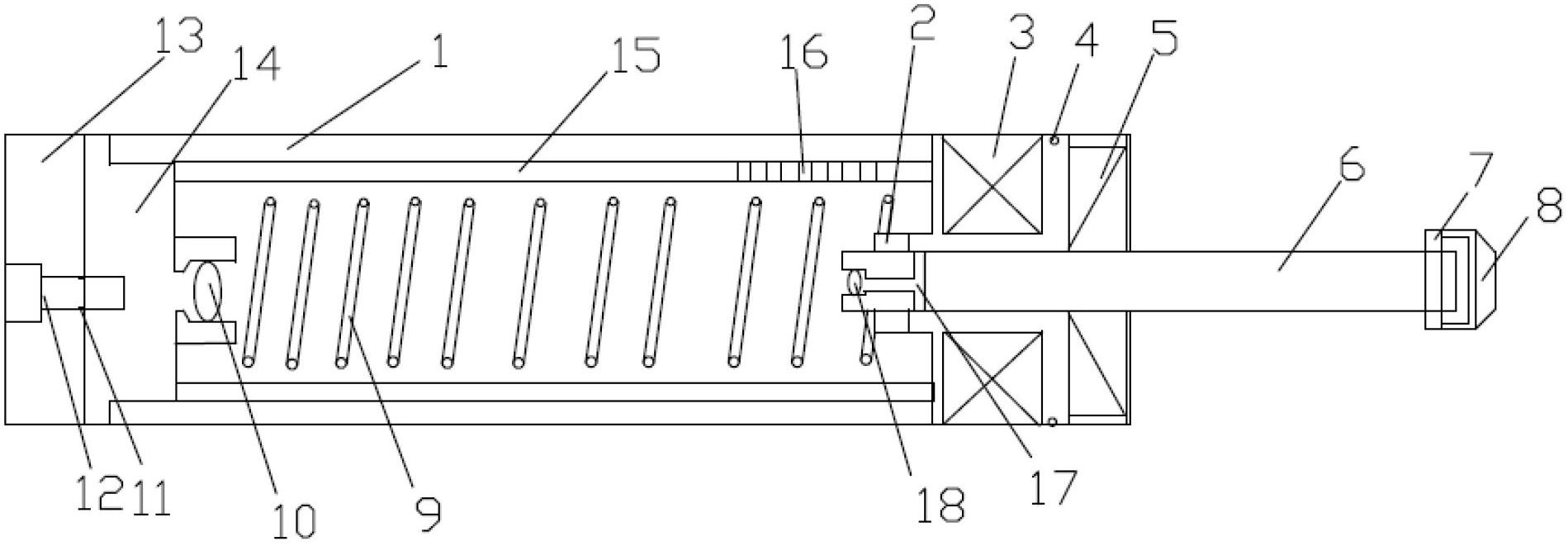

[0029] Such as Figure 1-Figure 3 Shown, the present invention is achieved through the following technical solutions:

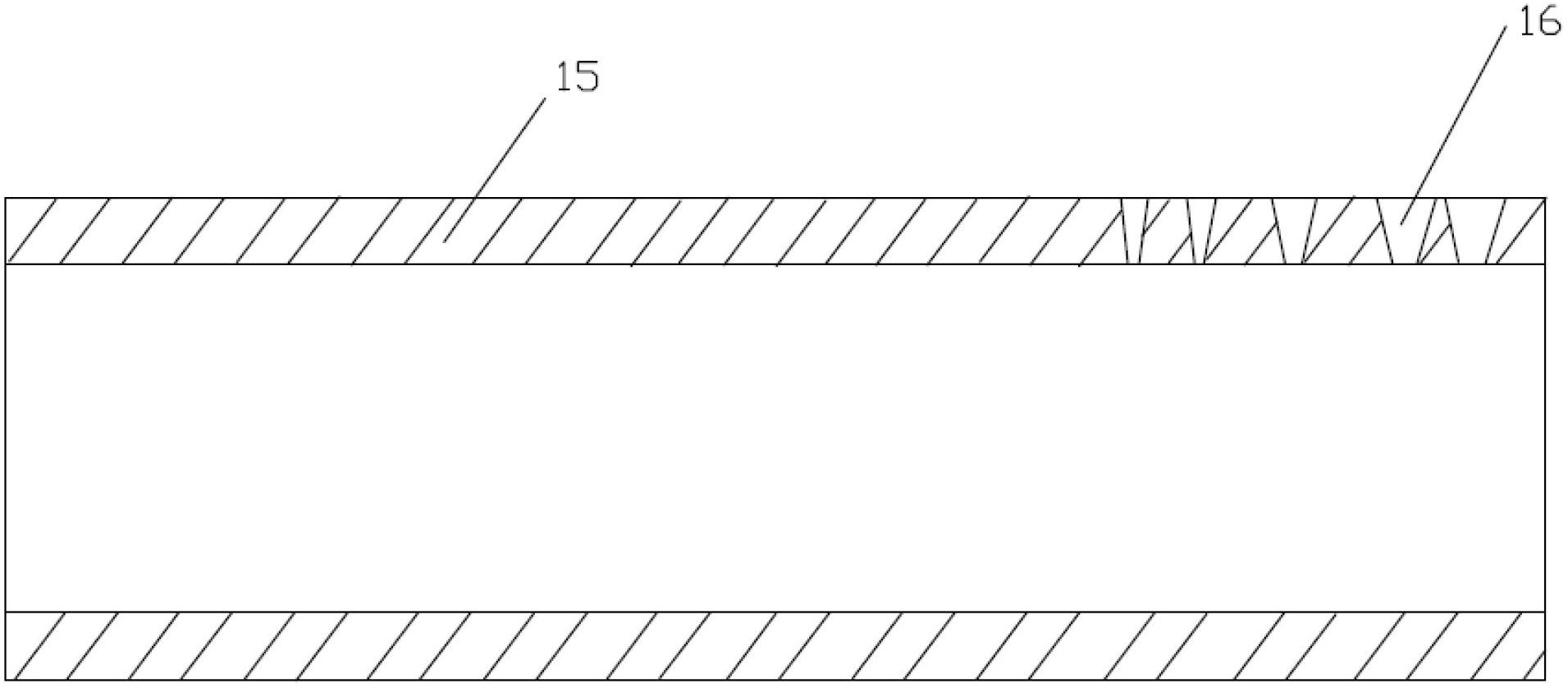

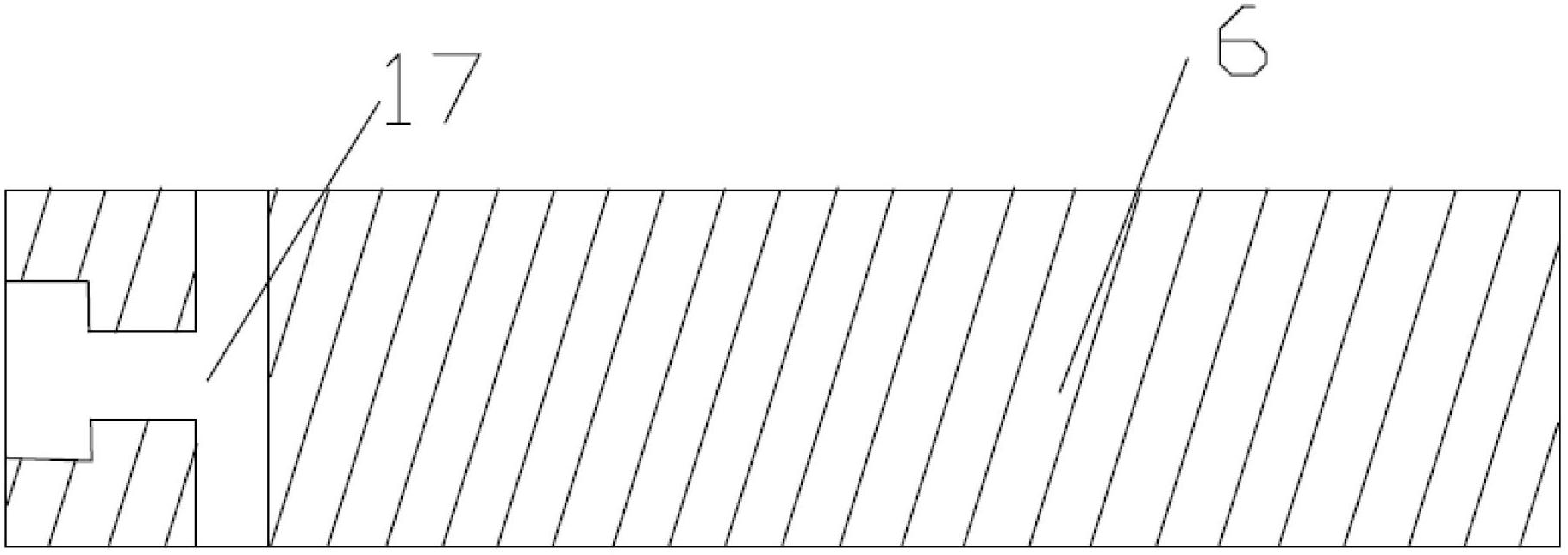

[0030] An oil pressure buffer, including a housing 1, a rear cover 14, an oil seal 5, an internal pressure cylinder 15, a piston 2, a piston rod 6, an impact head 7, a bearing 4, a spring 9, a pressure accumulator 3, and a flow adjustment plug 12 and the flow adjustment knob 13; the end of the piston rod 6 located in the internal pressure cylinder 15 is provided with an oil storage chamber 17, and the oil storage chamber 17 is opened at the axis of the end of the piston rod, and the opening is the same as that of the internal pressure cylinder The bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com