Display device, backlight module and frame unit

A backlight module and frame technology, which is applied to optical components, lighting devices, fixed lighting devices, etc., can solve the problems of scratching the liquid crystal panel and poor firmness of the plastic frame, so as to improve the service life, improve the stability and firmness, Displays the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

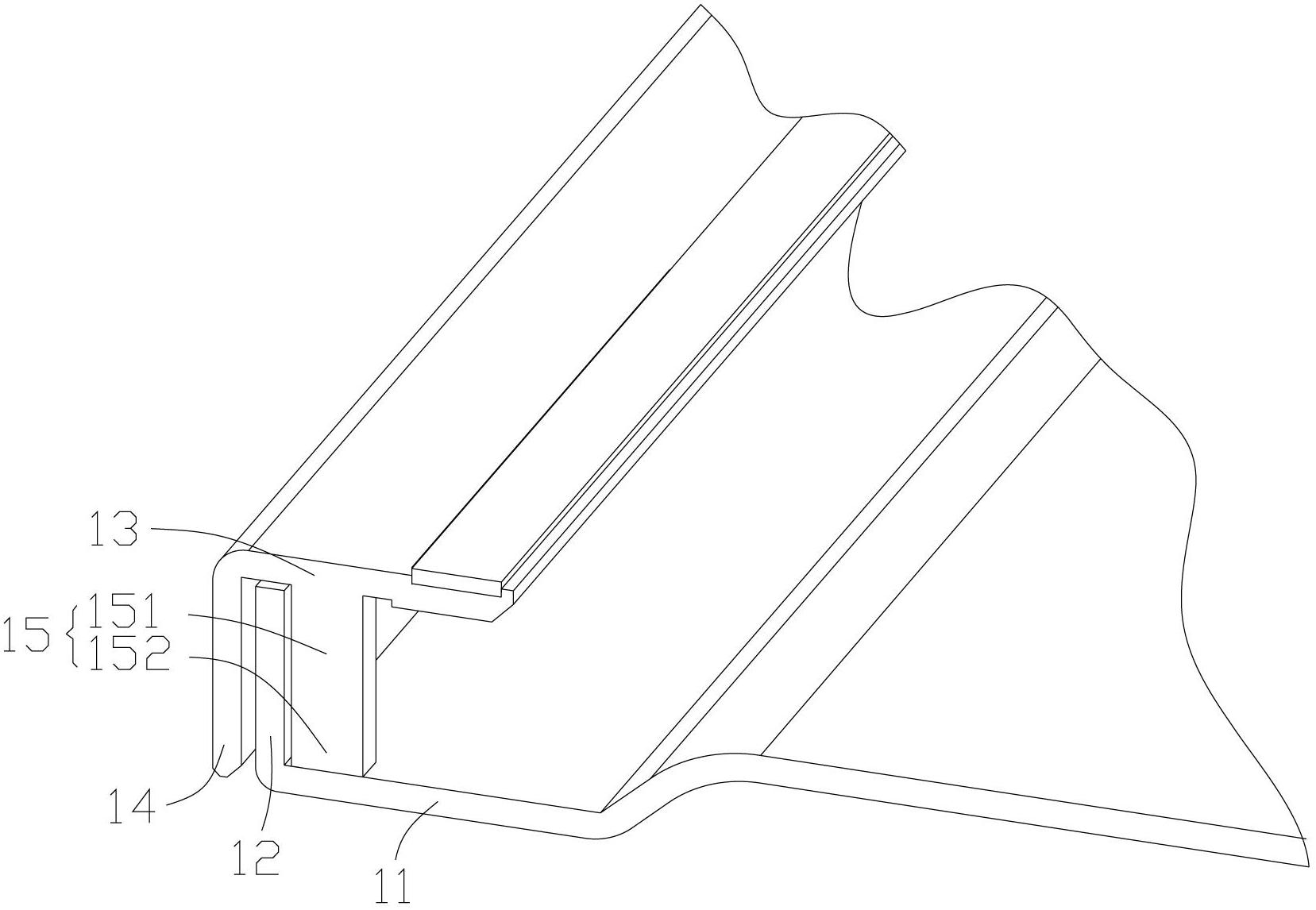

[0022] Example 1, please refer to figure 1 , is a partial structural schematic diagram of the first embodiment of the frame unit of the present invention.

[0023] The frame unit of this embodiment is preferably applied in a backlight module, which includes but is not limited to a back plate and a plastic frame that cooperate with each other, wherein the back plate includes but is not limited to the bottom 11 and the first side wall 12, and the plastic frame is Including but not limited to the bearing part 13 , the second side wall 14 and the supporting part 15 .

[0024] In this embodiment, the bottom 11 is used to carry the optical film of the backlight module, and the surface in contact with the optical film can be provided with elastic members to prevent damage to the optical film when vibrating, as understood by those skilled in the art within the scope, no further details are given.

[0025] The first side wall 12 is connected to the bottom 11. The first side wall 12 c...

Embodiment 2

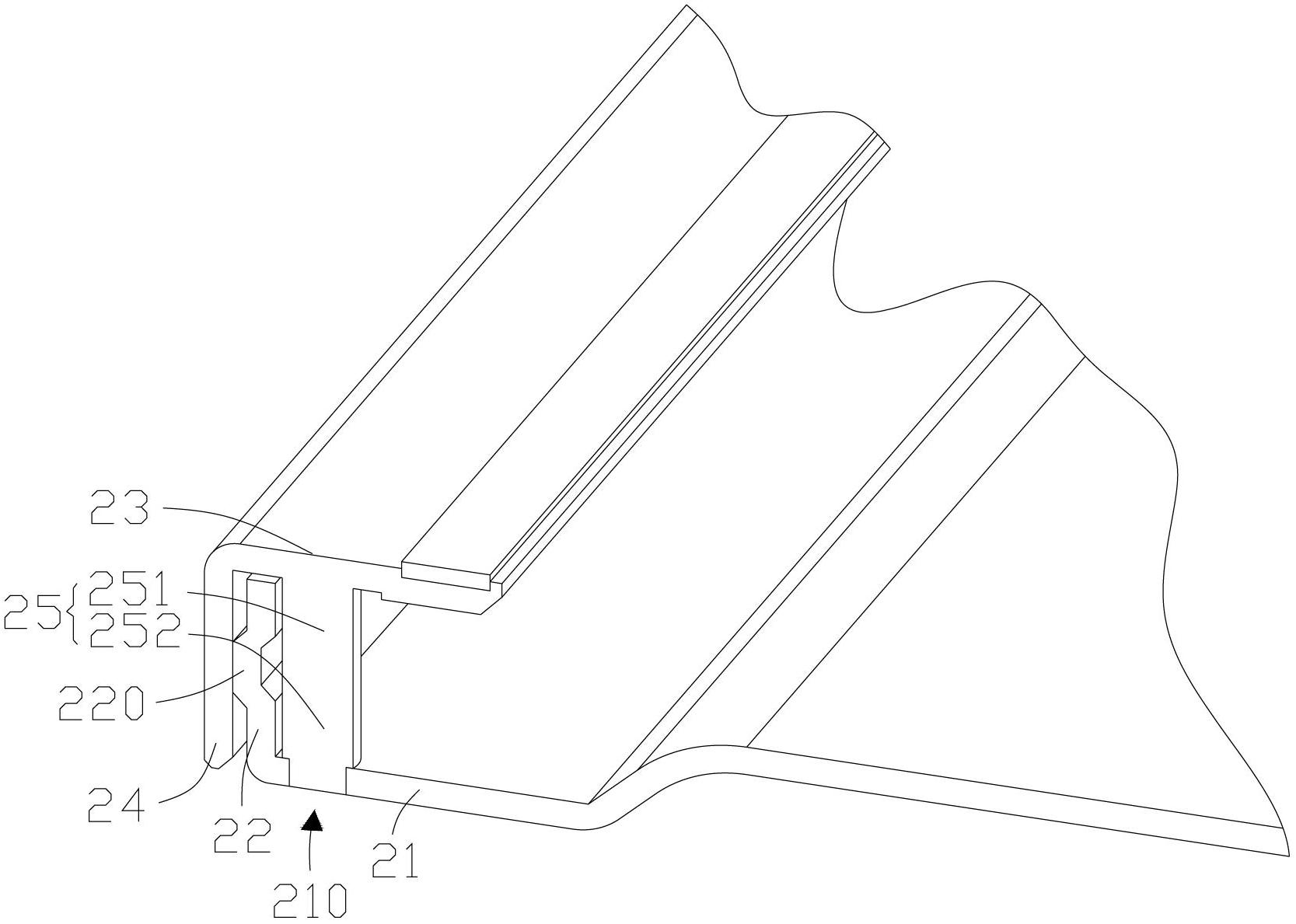

[0031] Example 2, please refer to figure 2 , is a partial structural schematic diagram of the second embodiment of the frame unit of the present invention.

[0032] The frame unit of this embodiment is preferably applied in a backlight module, which includes but not limited to a back plate and a plastic frame that cooperate with each other. As mentioned above, the back plate includes but not limited to the bottom 21 and the first side wall 22, and The plastic frame includes but is not limited to the bearing part 23, the second side wall 24 and the supporting part 25. The supporting part 25 includes the supporting body 251 and the positioning block 252. For the specific structure and matching method, please refer to the relevant description of the first embodiment. Within the scope of understanding of those in the technical field, details are not repeated here.

[0033] The difference between this embodiment and the first embodiment is that: the bottom 21 is provided with a f...

Embodiment 3

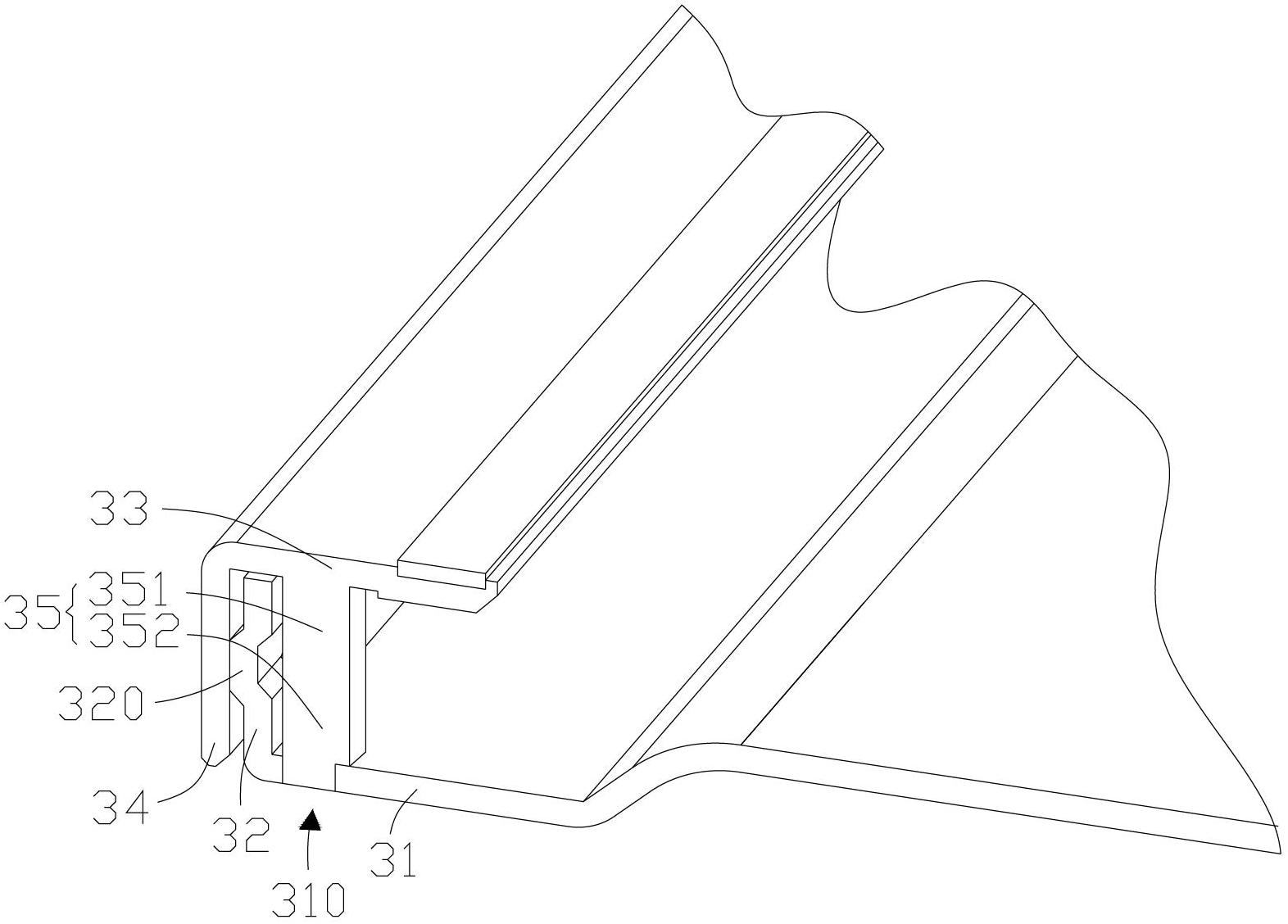

[0036] Embodiment three, please refer to image 3 , is a partial structural schematic diagram of the third embodiment of the frame unit of the present invention.

[0037] The frame unit of this embodiment is preferably applied in a backlight module, which includes but not limited to a back plate and a plastic frame that cooperate with each other. As mentioned above, the back plate includes but not limited to the bottom 31 and the first side wall 32, and The plastic frame includes but is not limited to a bearing part 33, a second side wall 34 and a support part 35. The support part 35 includes a support body 351 and a positioning block 352, and a fixing part 310 is provided on the bottom 31, and a fixing part 310 is provided on the first side wall 32. There is a tightening unit 320 on it, and for its specific structure and matching method, please refer to the relevant description of the second embodiment, and it will not be repeated within the scope of understanding of those sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com