Lead coil forming machine for fireworks and crackers

A technology of fireworks and firecrackers and wire machines, which is applied to pyrotechnics, weapon types, offensive equipment, etc., can solve problems such as low safety and impact on productivity, and achieve the effects of preventing accidents, rational structure, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the utility model is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

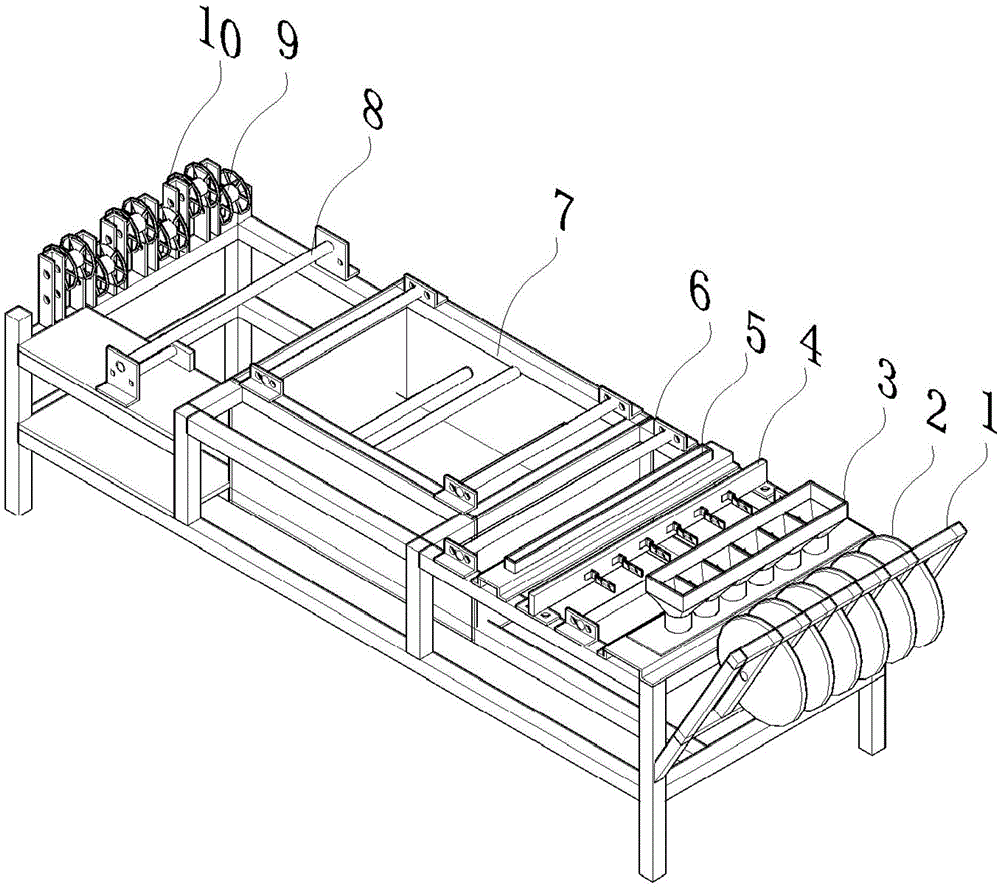

[0018] Such as figure 1 As shown, a fireworks and firecracker roll forming lead machine, its structure mainly includes a paper tray mounting frame 1, a medicine hopper 3, a lead roll forming device 4, a glue tank 5, a lead rod 6, a heating area 7, and a reciprocating rod 8, The lead reel support 10 and the frame, the medicine hopper 3 is installed between the paper tray mounting frame 1 and the lead reel forming device 4, a glue tank 5 is installed on the lead reel forming device 4 near the heating area 7, and the glue tank 5 5 and the lead roll forming device 5 are equipped with lead wire drawbars 6 on the left and right sides, and lead wire drawbars 6 are also installed in the heating area 7, and reciprocating moving rods 8 are installed between the heating area 7 and the lead plate suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com