Inner hole chamfer depth gauge

A gauge and chamfering technology, applied in the field of inner hole chamfering depth gauge and measuring and testing equipment, can solve the problems such as the unsuitability of inner hole chamfering depth measurement, the inability of the profiler to detect from time to time, and the inability to do batch testing, so as to achieve maintenance Easy, low cost, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

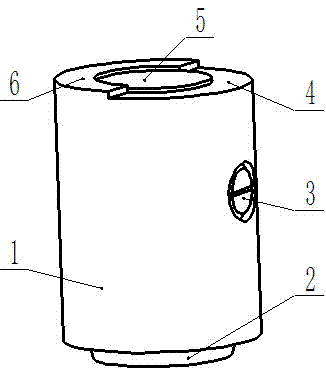

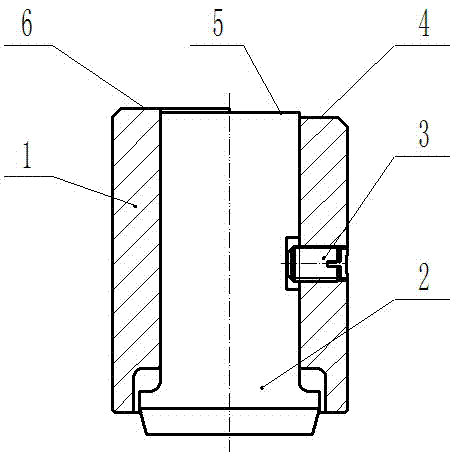

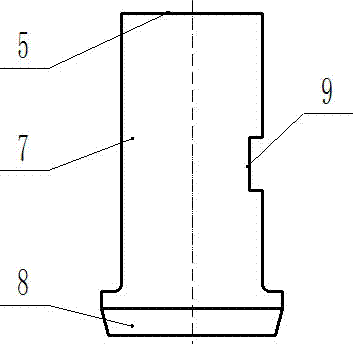

[0015] figure 1 , figure 2 Among them, the middle and upper part of the sliding measuring head 2 is a cylindrical sliding guide column matched with the gauge body 1, and a flat groove is opened on the corresponding height of its side, and the lower part is a cone measuring head for detecting the chamfering depth of the inner hole. The gauge body 1 is a hollow cylinder, the hollow part is formed by two upper and lower stepped holes, the inner cylindrical surface formed by the middle and upper holes cooperates with the sliding guide post, and the larger hole in the lower part is used to accommodate and make the cone measuring head in a certain position. Move up and down within the range. The top of the gauge body 1 is set as an upper semi-annular platform 6 and a lower semi-annular platform 4 with a certain height difference, which correspond to the minimum and maximum limits of the measured inner hole chamfer depth respectively. For the convenience of comparing the positiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com