Composite steel pipe defect detecting device and composite steel pipe defect detecting method

A composite steel pipe and defect detection technology, which is applied to measuring devices, instruments, and material analysis through electromagnetic means, can solve problems such as pipeline leakage, weld defects, cracks or inclusions, etc., to avoid interference, ensure quality, and effectively The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

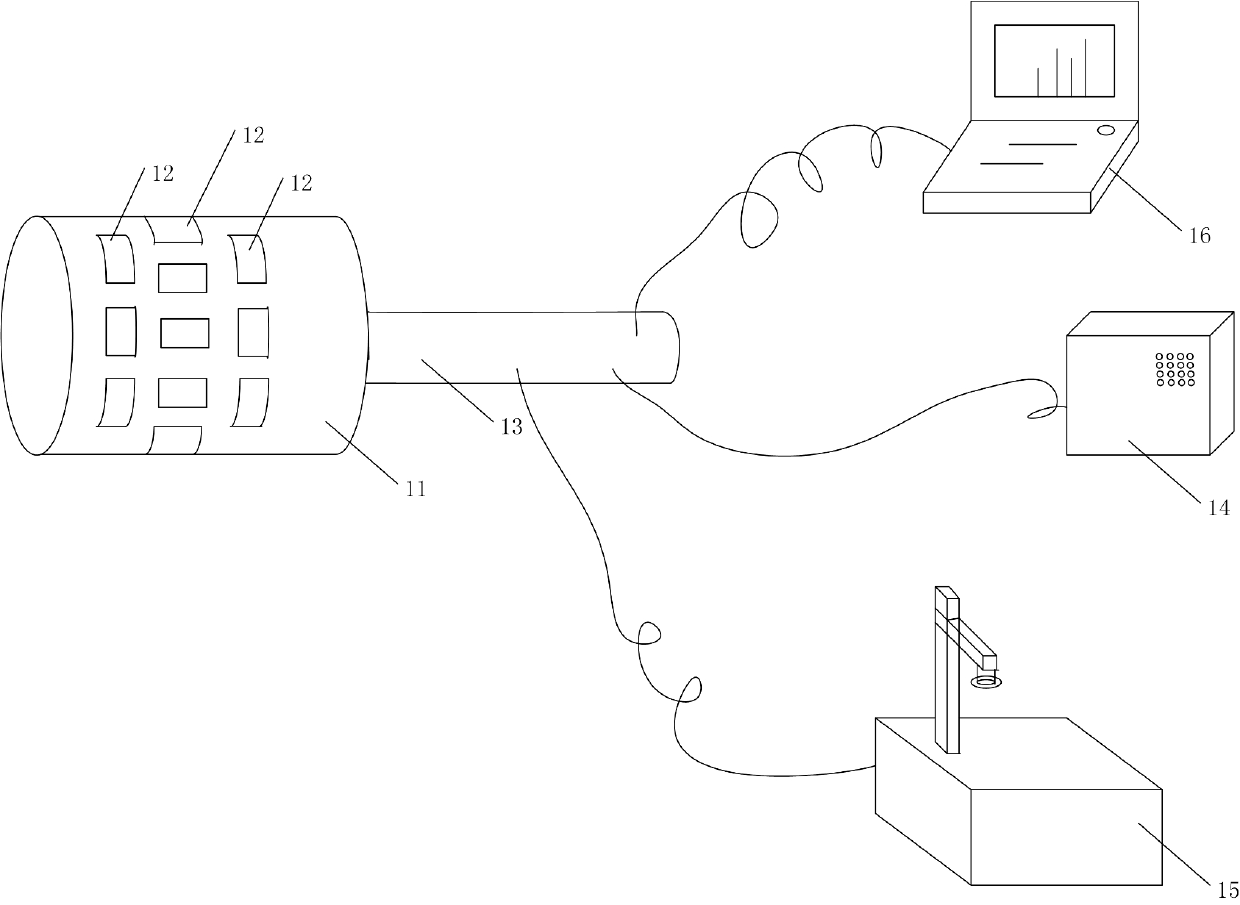

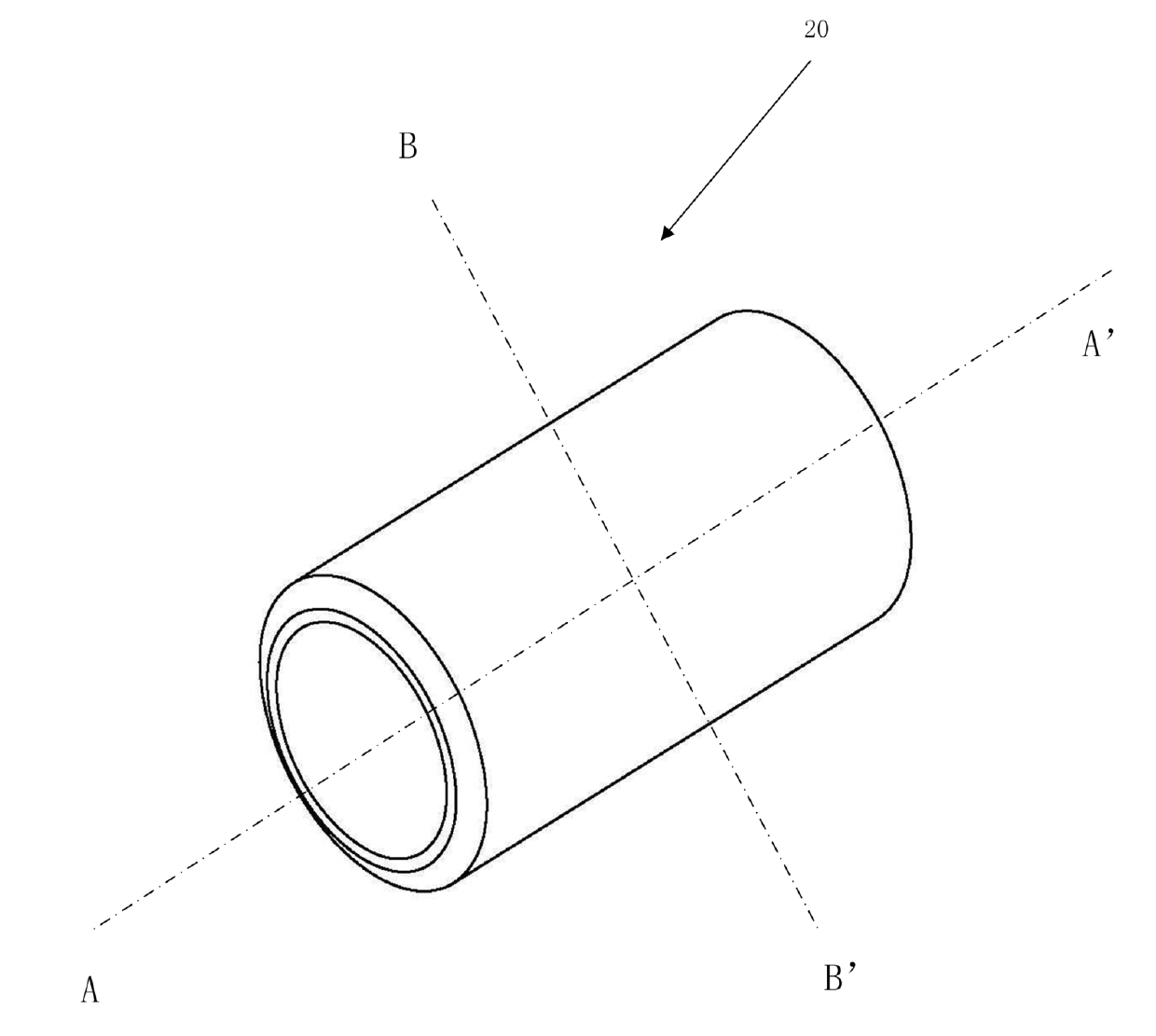

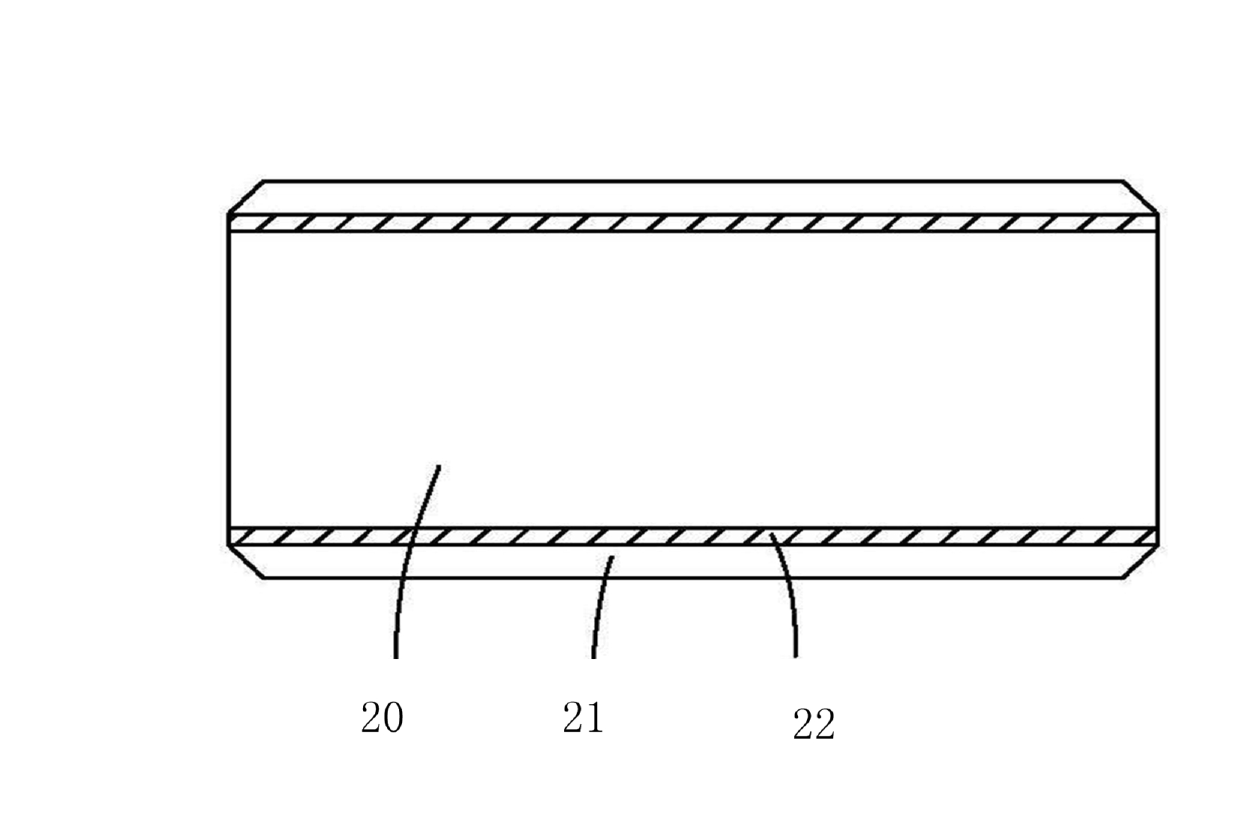

[0041] The specific implementations of the composite steel pipe defect detection device and the composite steel pipe defect detection method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0042] Based on the principle of electromagnetic induction, the invention uses the eddy current detection coil of the composite steel pipe defect detection device to detect the defect of the composite steel pipe to be inspected in the way of passing through, when the eddy current detection coil passes through a discontinuity defect in the inner wall of the composite steel pipe to be inspected , the eddy current magnetic field changes due to the existence of defects in the compound steel pipe to be inspected, and the change of the eddy current magnetic field in turn causes the impedance of the eddy current detection coil to change. By analyzing the impedance amplitude and phase in the impedance plane diagram, it is judged whether the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com