Pressurized thin-layer chromatography development chamber

A technology of thin-layer chromatography and expansion chamber, which is applied in the field of pressurized thin-layer chromatography, can solve the problems of complex structure, bulky volume, and high cost of the pressurized expansion chamber, and achieve uniform force, improved connection strength, and simplified structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

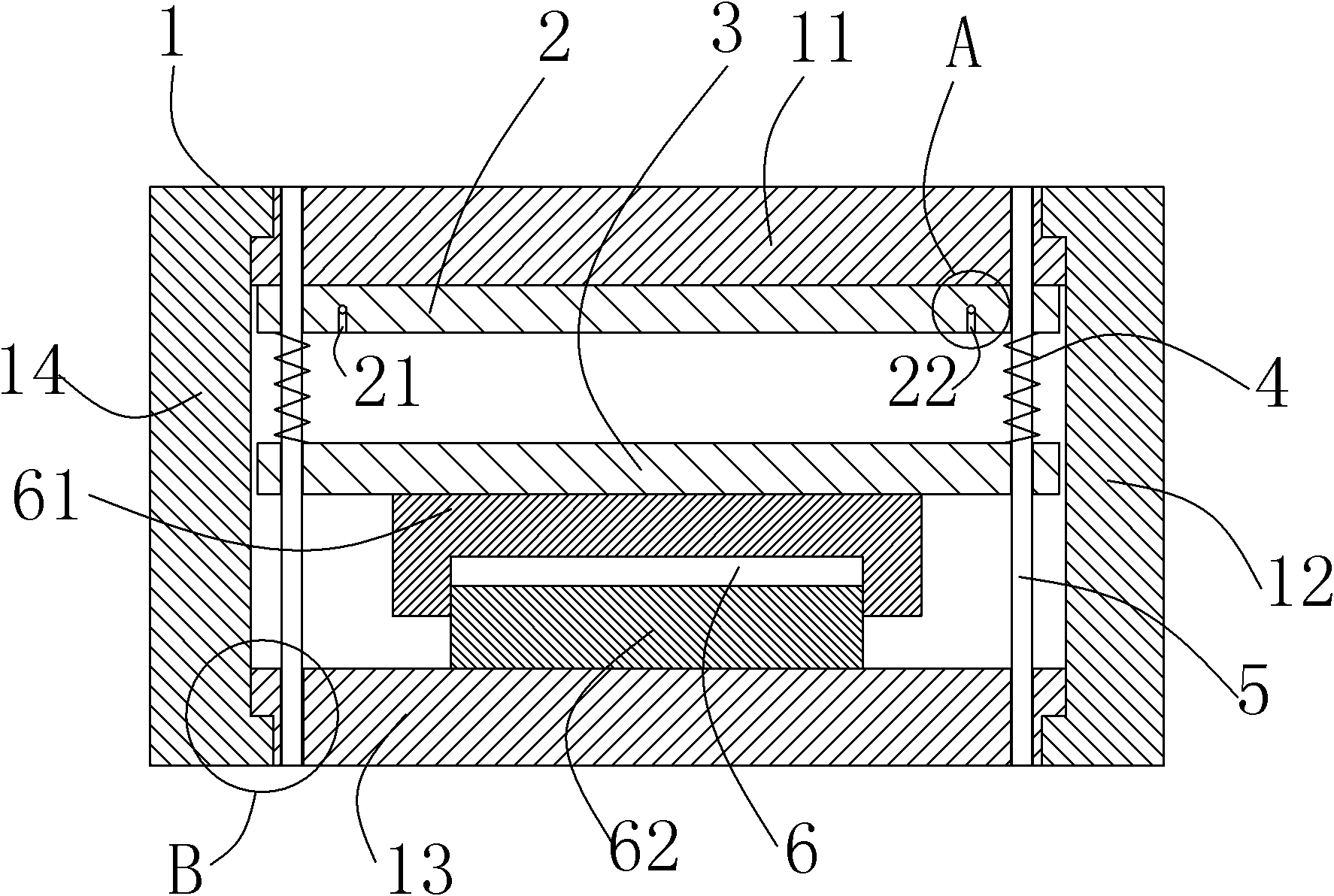

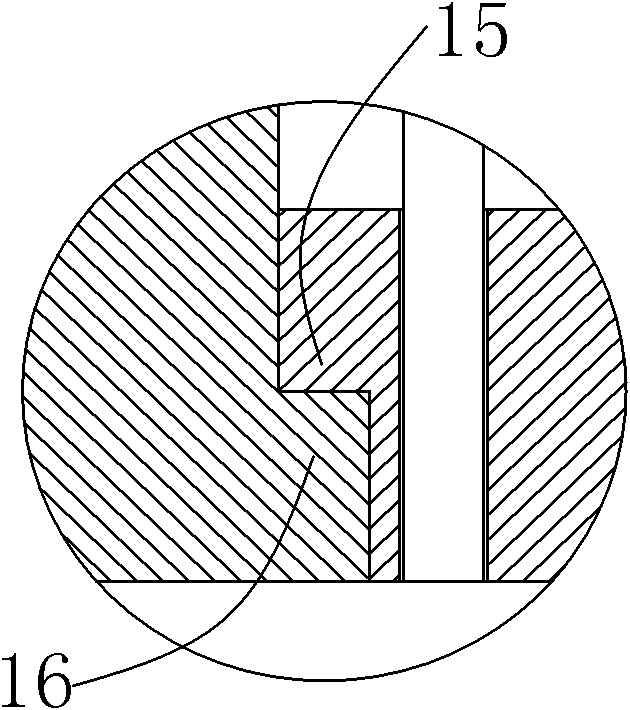

[0031] Such as figure 1 As shown, the pressurized TLC development chamber of the present invention includes a pressure ring 1, a top plate 2 and a bottom plate 3 are arranged in the pressure ring 1, the top plate 2 is fixed on the top of the pressure ring 1, and a pressure ring 1 is also provided with There are at least two guide pillars 5, and the bottom plate 3 is installed on the guide pillars 5, and can slide up and down along the guide pillars 5. The bottom surface of the bottom plate 3 is seated on the upper end of an ultra-thin hydraulic cylinder 6 , and the lower end of the ultra-thin hydraulic cylinder is supported on the bottom of the pressure bearing ring 1 . The plate clip that the plate column is installed is just placed between the top plate 2 and the base plate 3.

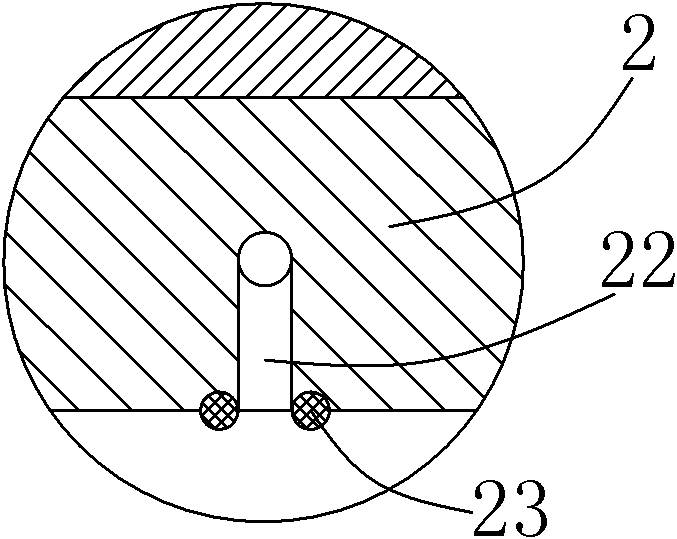

[0032] The top plate 2 is provided with a developer inlet 21 and a developer outlet 22, and the other ends of the developer inlet 21 and the developer outlet 22 are respectively connected to externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com