Unlocking mechanism of SFP (small form pluggable) optical modules

A technology of unlocking mechanism and optical module, applied in the direction of coupling of optical waveguides, etc., can solve the problems of lock head detachment, large unlocking force, inconvenient operation, etc., and achieve the effects of small unlocking resistance, small unlocking force, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

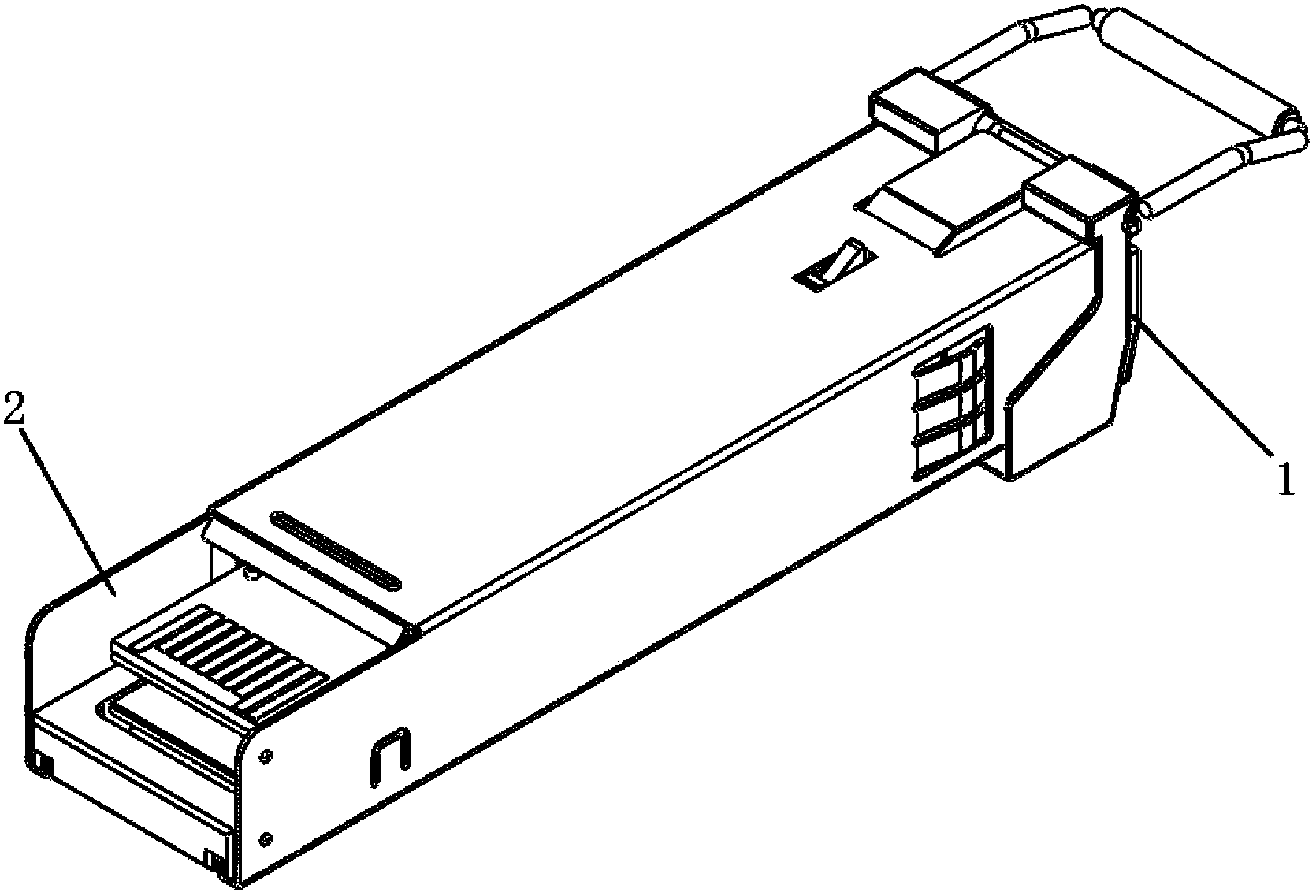

[0036] Such as figure 1 As shown, the unlocking mechanism of an SFP optical module in this embodiment includes an SFP optical module provided with an optical port 1 and an electrical port 2. Unlock and pull out from the cage.

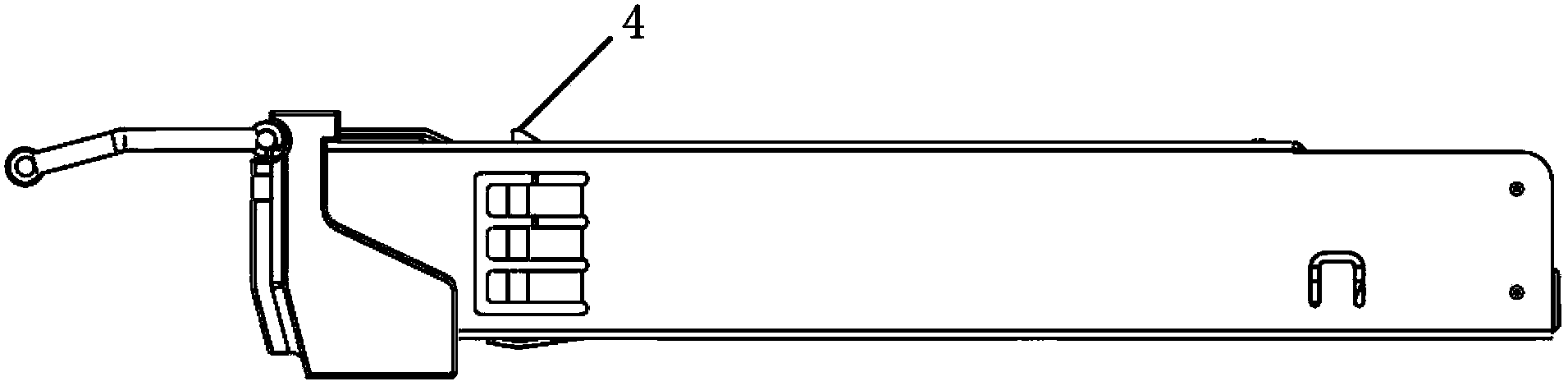

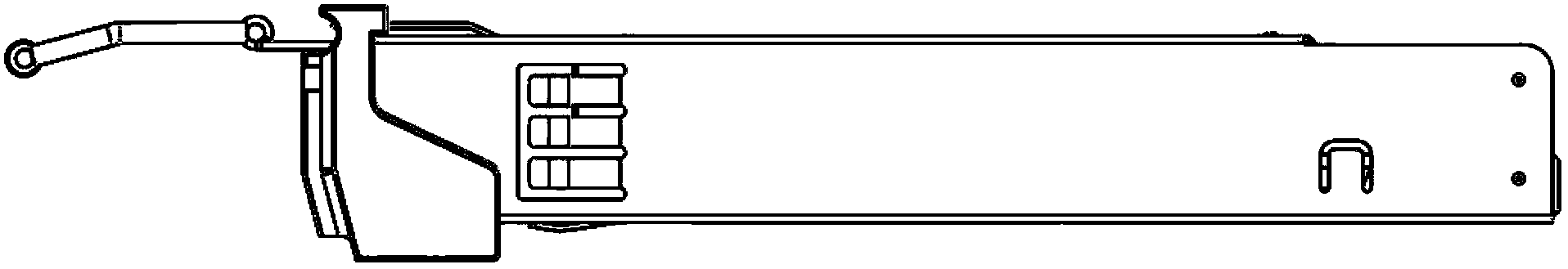

[0037] For the process of locking and unlocking the optical module and the cage of the switch, please refer to figure 2 , image 3 and Figure 4 : When the optical module is locked with the cage of the switch, the locking head 4 protrudes from the inside of the optical module through the lock hole 3 to the top surface of the optical module, and is locked with the cage of the switch, thereby preventing the optical module from being released from the cage. When the optical module needs to be unlocked from the cage of the switch, the lock head 4 is retracted from the lock hole 3 to the inside of the optical module, and the clamp connection between the lock head 4 and the cage is released, and the optical module can be released. The module is pulled ou...

Embodiment 2

[0044] Such as Figure 1 to Figure 8 As shown, in the unlocking mechanism of the SFP optical module in this embodiment, the middle part of the rotating arm 5 is hinged with the optical module, the lock head 4 is arranged at one end of the rotating arm 5, and the other end of the rotating arm 5 can be connected with the elastic reset device, and the lever The mode of drive lock head 4 resets. The elastic resetting device is a bend 7 provided on the optical module. The bend 7 is punched by the housing 10 and then bent upward. When unlocking, the arm 5 is pressed against the bend 7 . Using the top surface of the optical module housing 10 after punching and bending 7 as an elastic reset mechanism not only has good elasticity, but also has a simple structure and takes up little space, which is beneficial to the arrangement of the inner space of the optical module.

[0045] Such as Figure 9 As shown, in this embodiment, the bend 7 is located on the housing 10 above the end of the...

Embodiment 3

[0050] Such as Figure 1 to Figure 9 As shown, in the unlocking mechanism of the SFP optical module in this embodiment, a pull plate 12 is provided between the module base 9 and the housing 10, the pull plate 12 is fixedly connected to the unlocking slider 6, and the upper surface of the module base 9 is provided with a chute 11 , the bottom surface of the pull plate 12 is slidably matched with the top surface of the chute 11, and the pull plate 12 arranged on the chute 11 drives the translation of the unlocking slider 6, which is beneficial to guide the moving direction of the unlocking slider 6. The pull plate 12 is connected with a pull rod 13 on the side close to the optical port 1, and the pull rod 13 is exposed at one end of the optical port 1 of the optical module. Pull out the pull plate 12 and drive the unlocking slider 6 to move to unlock. The pull plate 12 is provided with a through groove 12b, and the rotating arm 5 is arranged inside the through groove 12b, so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com