Component Locking Structure

A technology for locking structures and components, which is applied to the components of connecting devices, electrical components, coupling devices, etc., and can solve problems such as unlocking the housing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

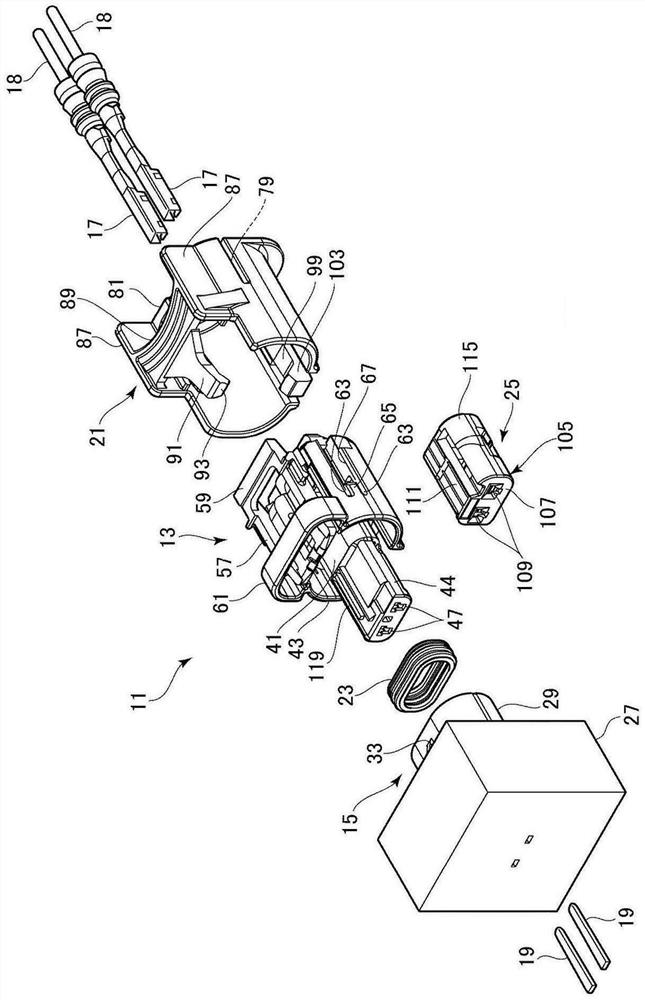

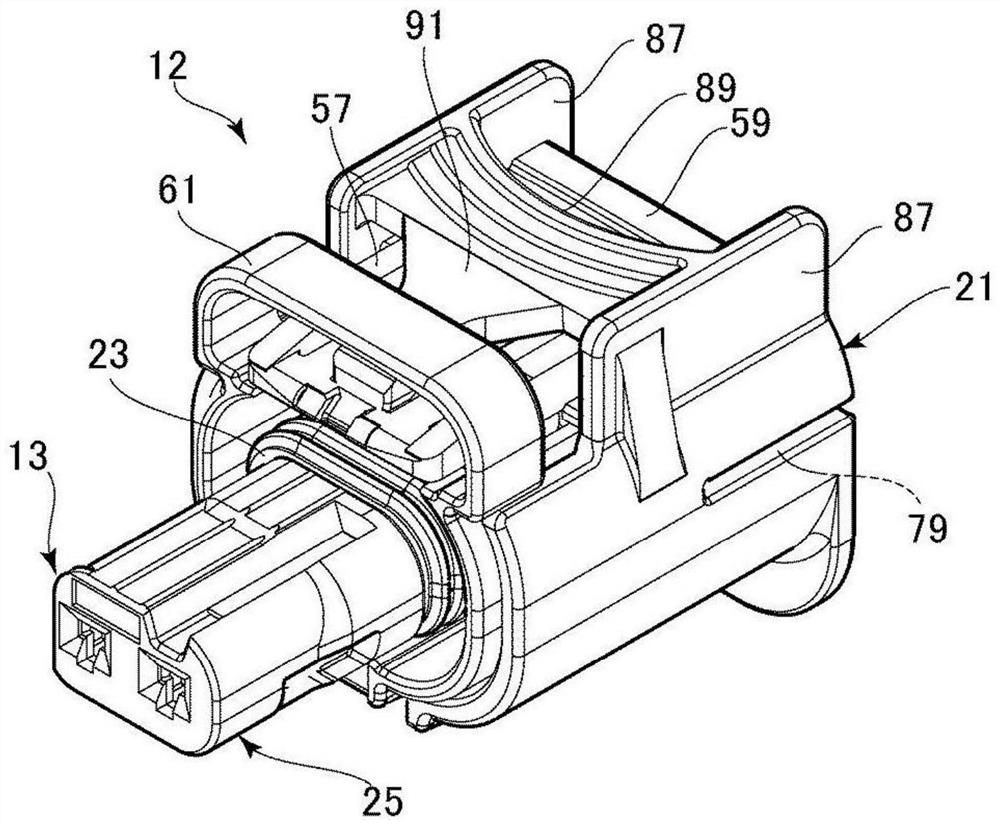

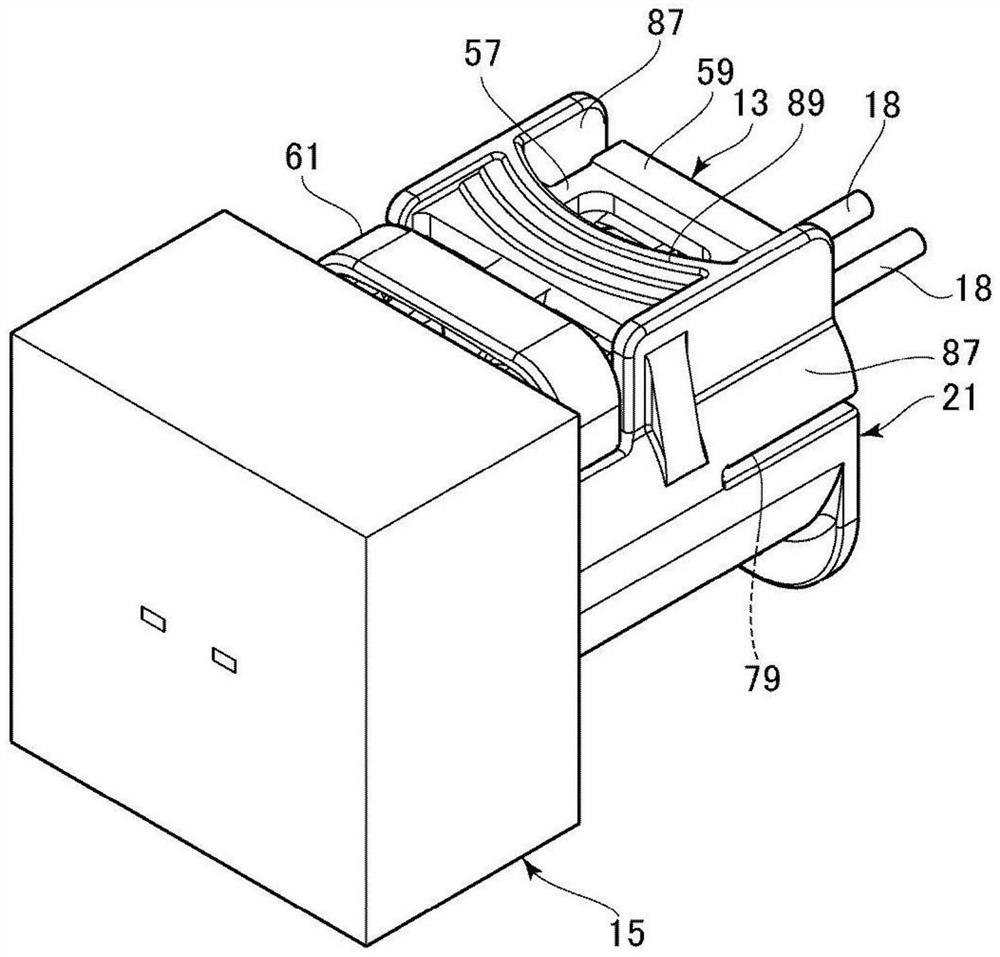

[0103] Embodiments of a connector embodying the present invention will be described below with reference to the drawings. figure 1 is an exploded perspective view of the connector 11 according to the present embodiment. figure 2 is a perspective view of the appearance of the female connector unit (connector unit) 12 in which the CPA 21 , the sealing member 23 and the side holder 25 have been mounted on the female housing 13 . image 3 It is a perspective view of the appearance of the mated state of the connector. Figure 4 to Figure 8 is a longitudinal sectional view showing the movement between the connector before mating and the final locking of the CPA. Incidentally, hereinafter, the direction of mating to the mating connector will be described as forward (forward in the mating direction); the direction of separation from the mating connector will be described as backward (backward in the mating direction); Intersect (approximately orthogonally intersect) on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com