Device connector and manufacture method thereof

一种连接器、设备的技术,应用在其制造或模制领域,达到改进制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

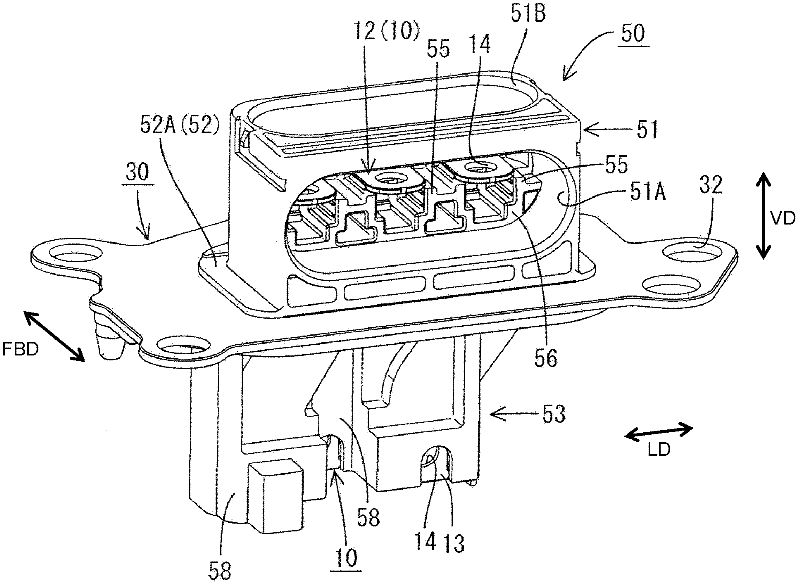

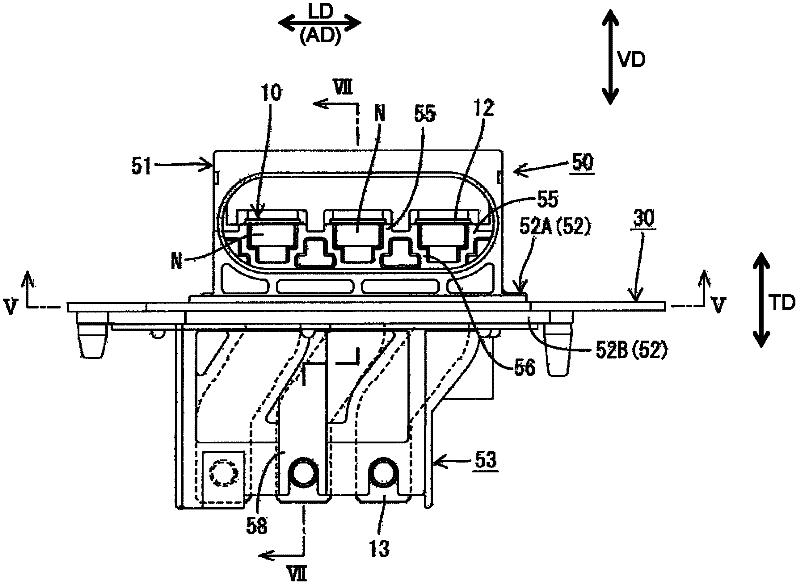

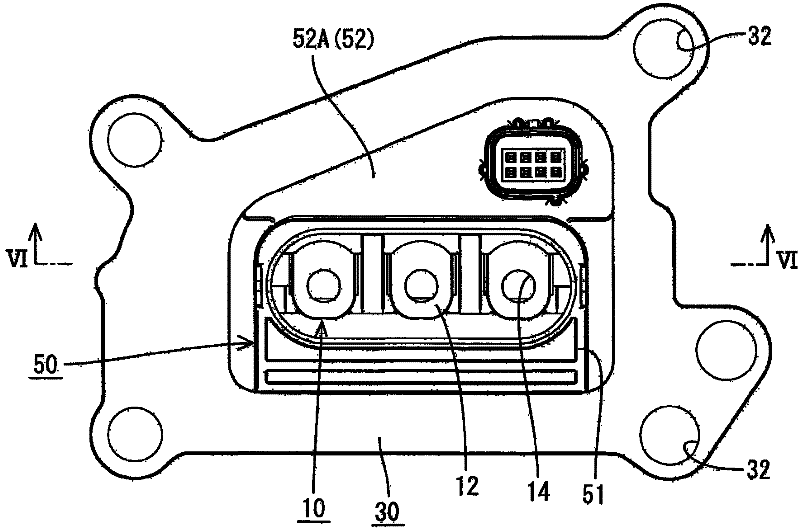

[0061] refer to Figures 1 to 13 A specific embodiment of the present invention is described.

[0062] In this embodiment, shown as an example of a device connector is a terminal block that can be connected to a metal motor housing (not shown) in which the motor (as an example of a "device") is housed. in the metal motor housing. Such as figure 1 As shown, the terminal block includes: a metal plate 30 capable of being attached and fixed to a motor housing; a connector housing 50 integrally molded with the metal plate 30; and one or more (eg, three) conductive plates 10, particularly Accordingly, the conductive plate is held or accommodated in the connector housing 50 while penetrating through the metal plate 30 in the plate thickness direction TD. Note that the connector housing 50 specifically corresponds to a molded resin portion, and the one or more conductive plates 10 specifically correspond to conductors.

[0063] One or more ends (first ends) of the conductive plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com