Wear assembly for excavating equipment

一种挖掘设备、磨耗的技术,应用在移土机/挖土机、建筑等方向,能够解决增加挖泥作业时间和费用、不紧固等问题,达到减少阻力、降低功耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

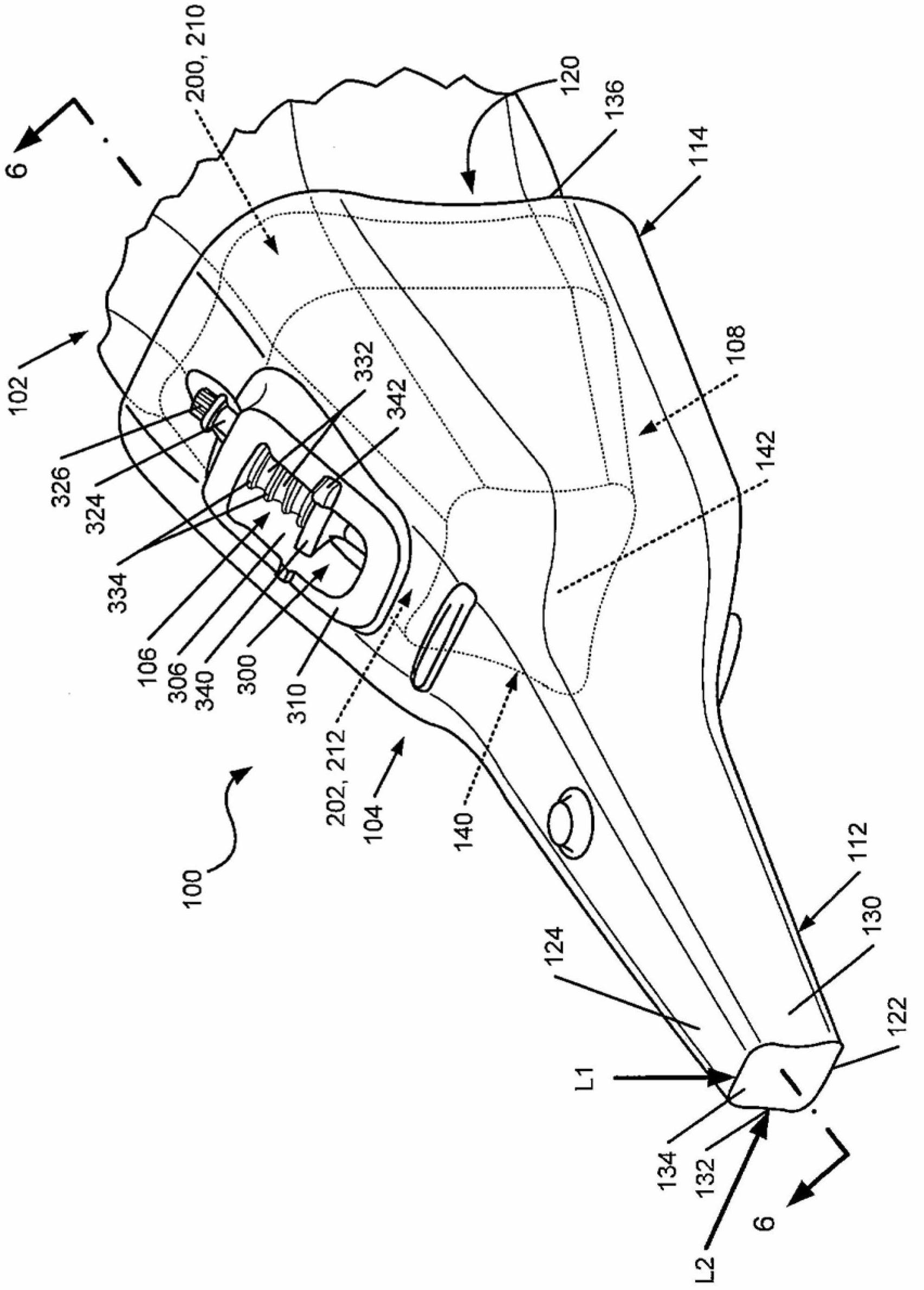

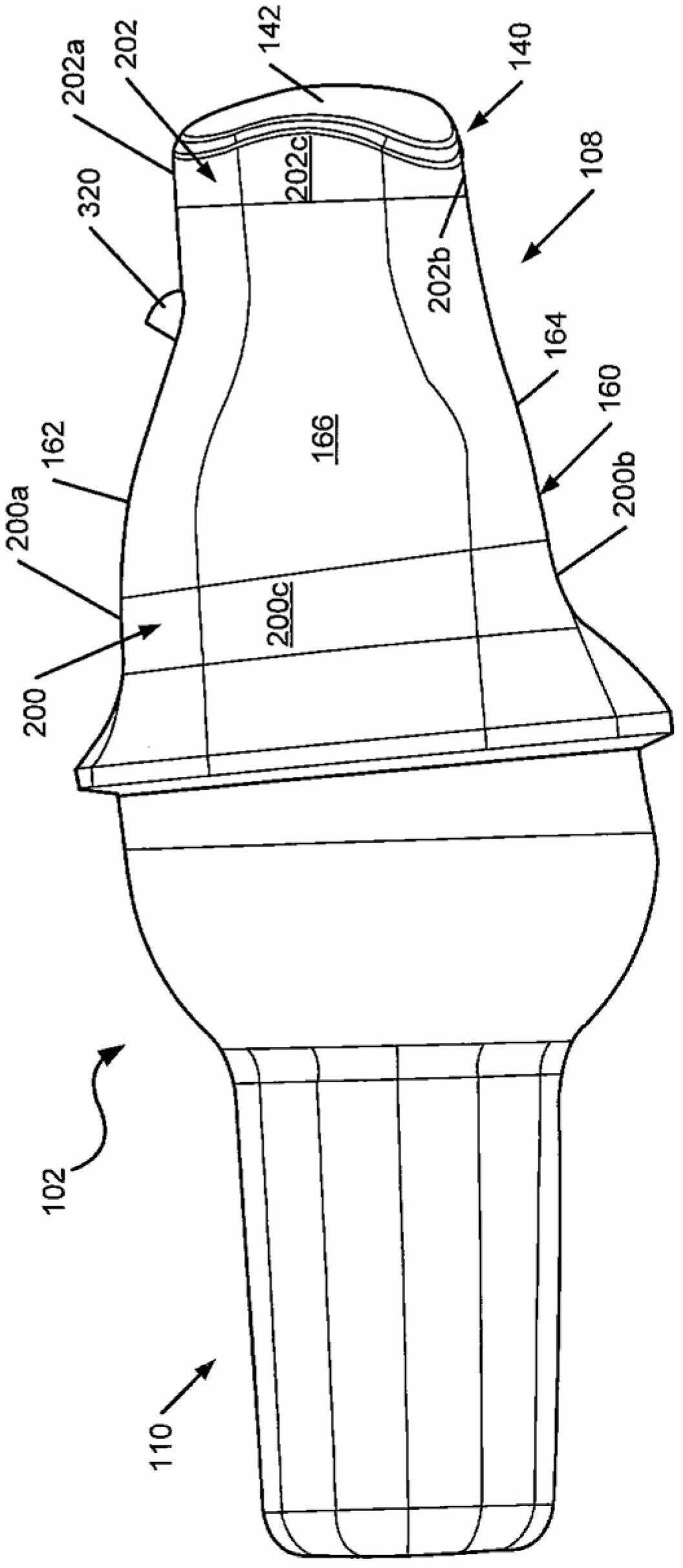

[0047] The following description and drawings disclose exemplary features of excavation equipment, including wear member structures for excavation equipment and structures for mounting the wear members according to examples of the present invention.

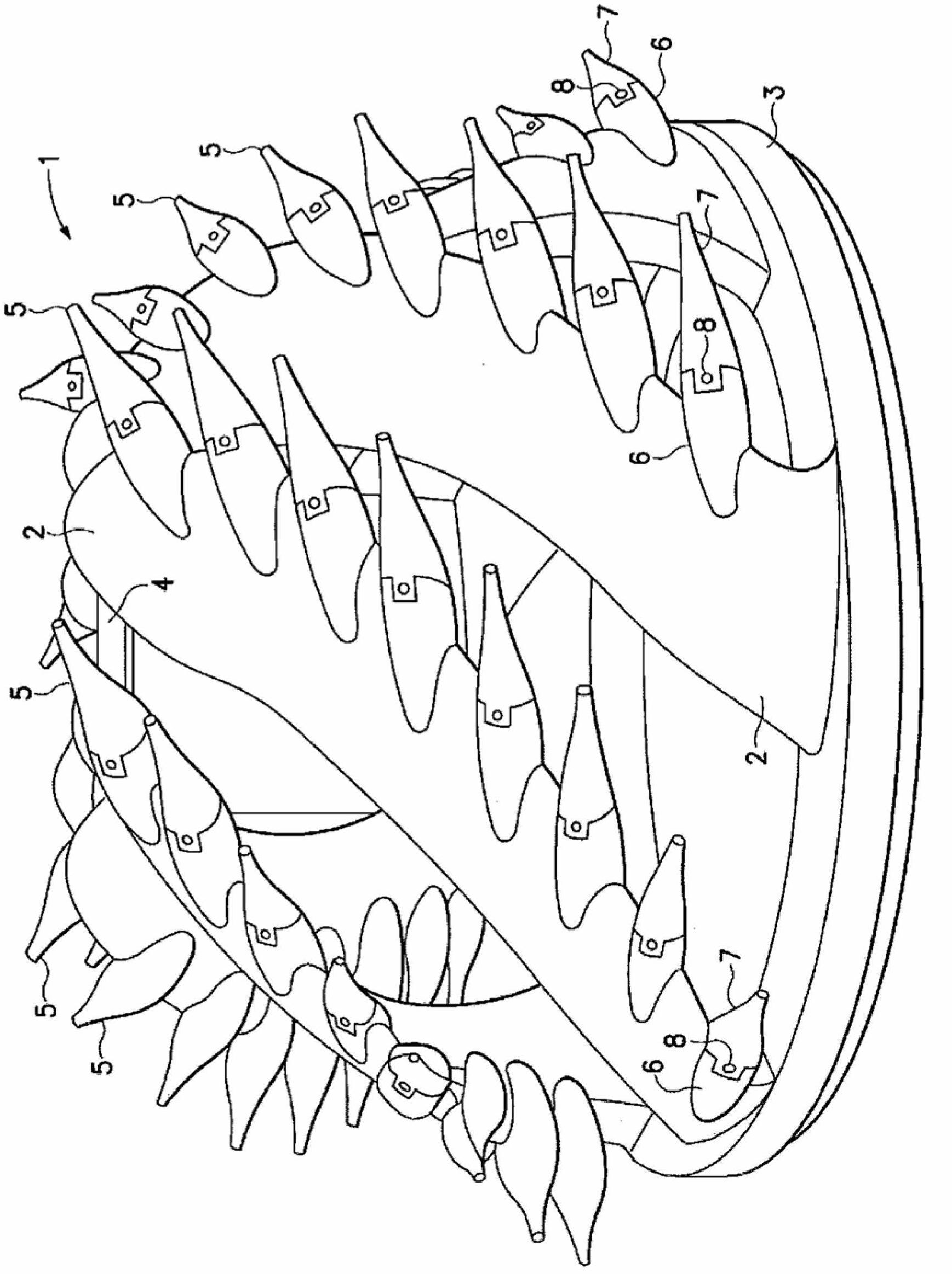

[0048] Aspects of the invention relate to wear assemblies 100 for excavation equipment that may be particularly well suited for dredging operations. In this application, the invention is mainly described in terms of dredging teeth adapted to be attached to a dredger cutter head. However, different aspects of the present invention may be used in conjunction with other types of wear assemblies (eg, pipe covers), and with other types of excavating equipment (eg, buckets for construction or mining equipment, etc.).

[0049] Assembly 100 and / or portions thereof are often described in relative terms such as "upper," "lower," "horizontal," "vertical," "front," and "rear," and the like. Such terms are not considered necessary and are me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com