Electrically-assisted engine braking

An engine braking and generator technology, applied in engine control, engine components, combustion engines, etc., to solve problems such as battery degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

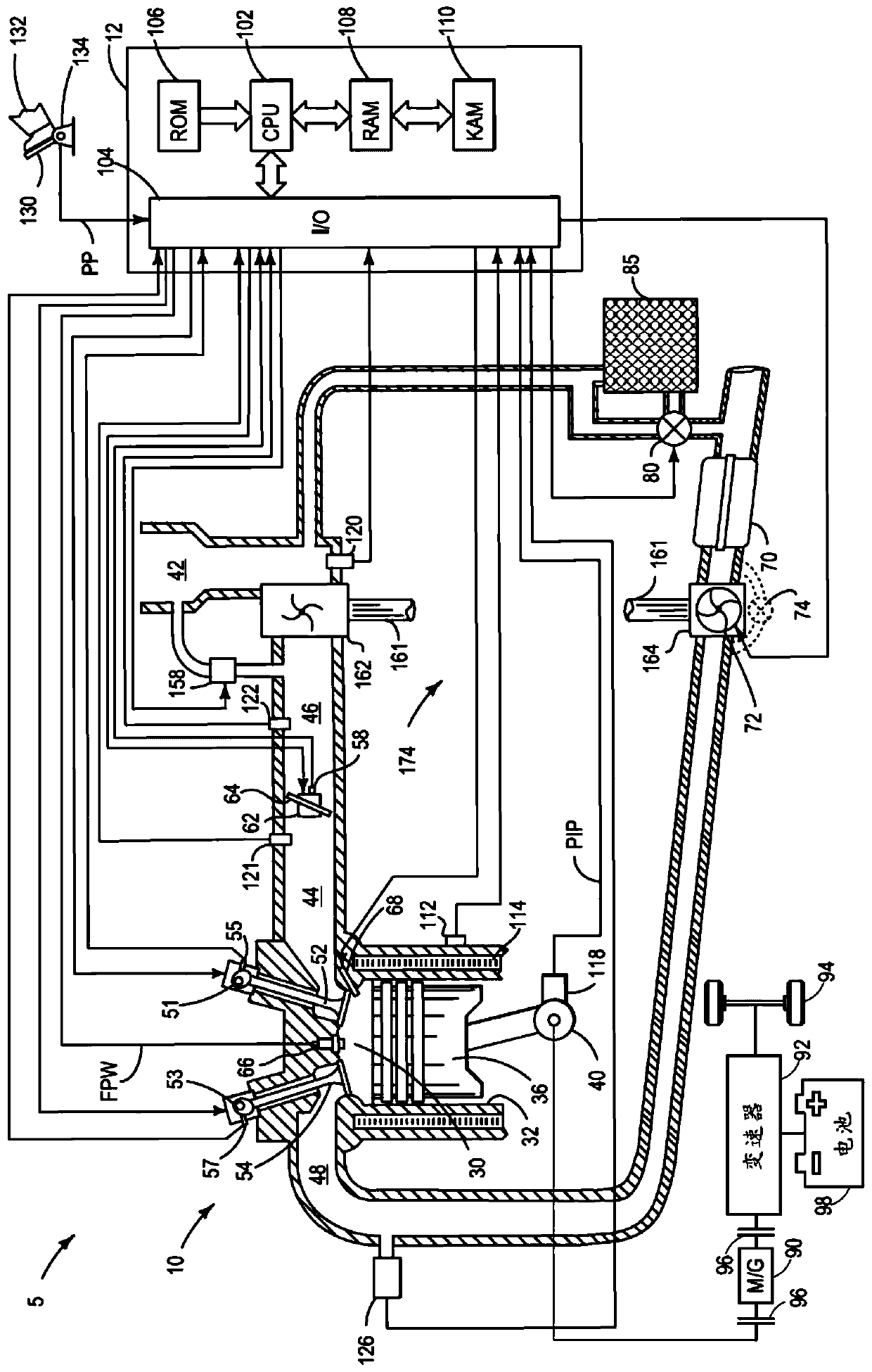

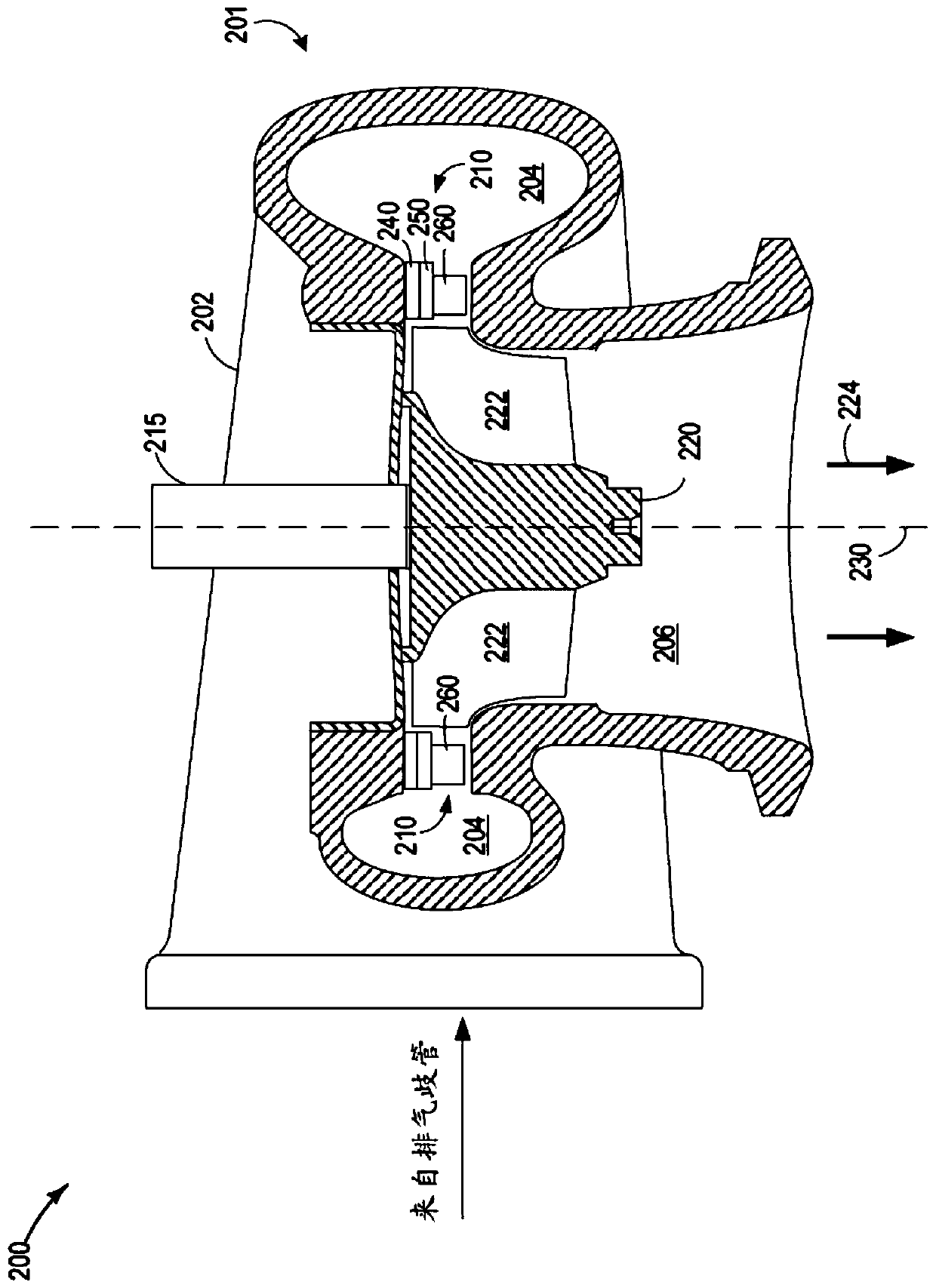

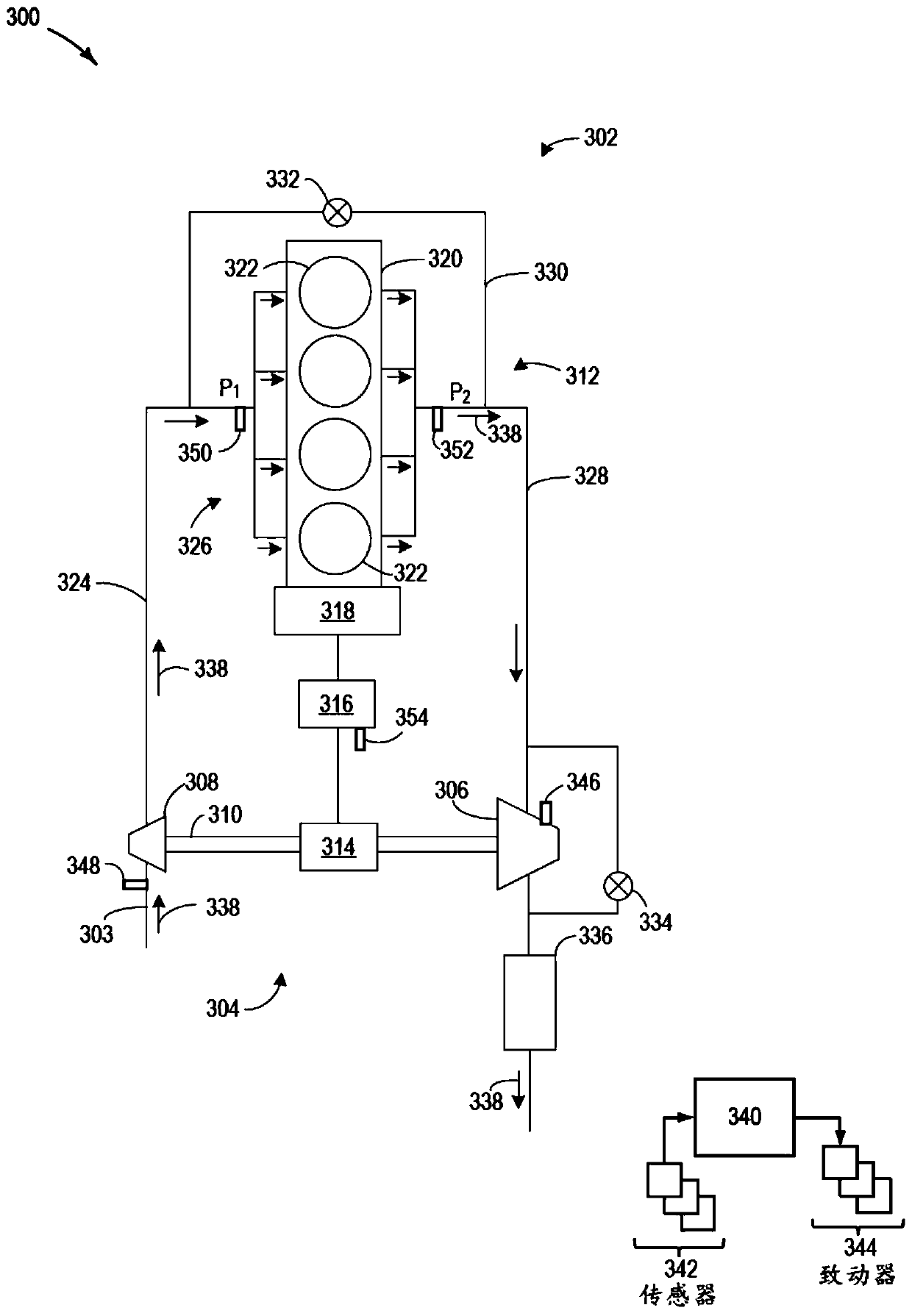

[0017] The following description relates to systems and methods for increasing engine braking power while maintaining use of regenerative braking. Exhaust braking can be used in diesel engines to use increased exhaust manifold pressure to counteract the engine's compression stroke and slow the engine down. Regenerative braking may be used in conjunction with exhaust braking to provide additional braking force while recovering braking energy to recharge the vehicle's electrical storage device. Therefore, the coordinated use of exhaust braking and regenerative braking may be particularly attractive for hybrid electric vehicles (HEVs), which include a traction battery to propel the HEV, thereby reducing the use of mechanical friction brakes and increasing the HEV's fuel consumption. economy. However, an upper bound on the braking torque provided by exhaust braking can be attributed to the intake air flow to the engine. This problem can be addressed by engine braking methods tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com