Device for indexing and resetting paper-based friction plate during attaching

A paper-based friction plate and reset device technology, which is applied in the field of indexing and reset devices for paper-based friction plate patches, can solve the problems of simultaneous positioning, indexing, and reset, and achieve improved indexing accuracy, production efficiency, and The effect of expanding the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

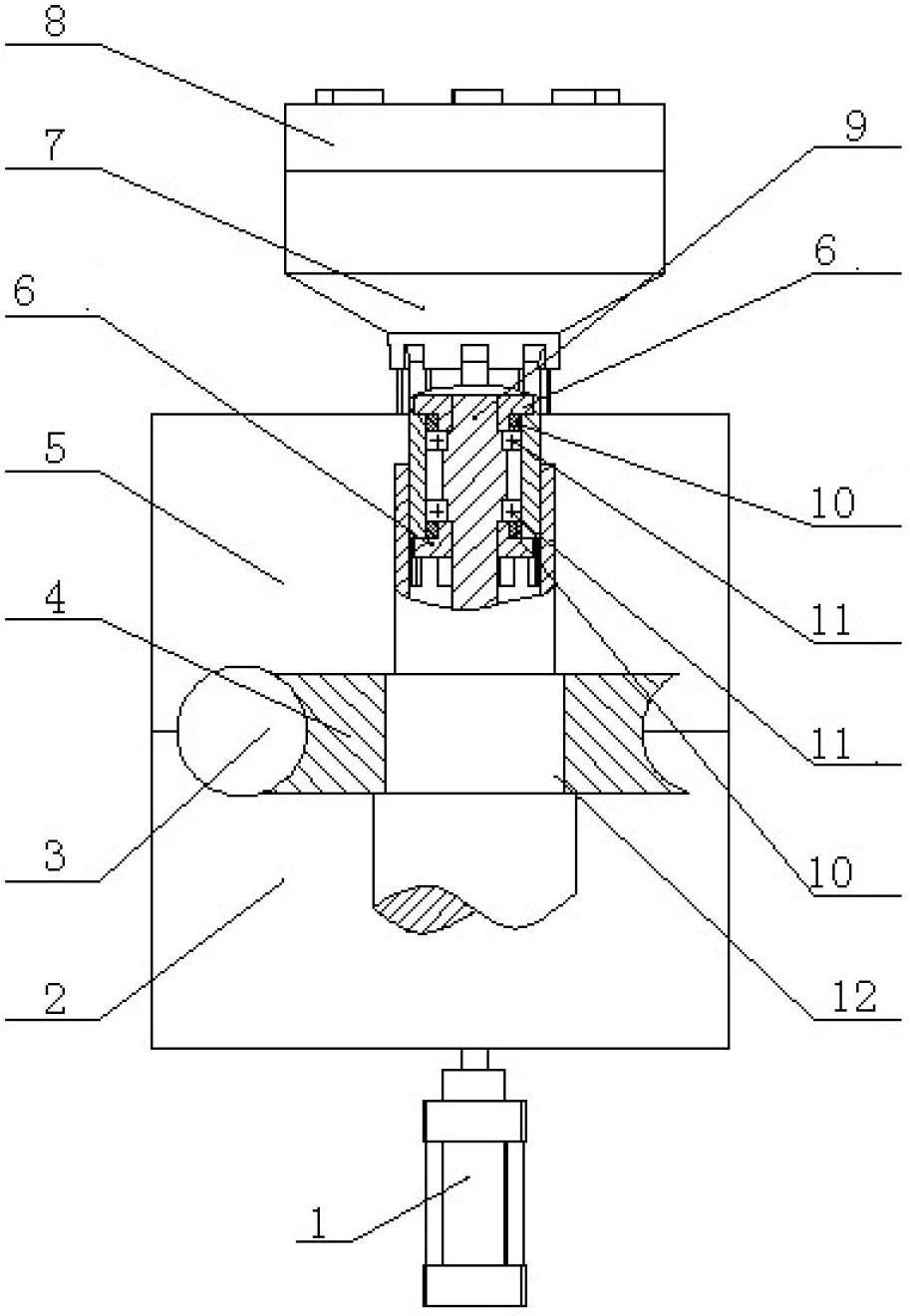

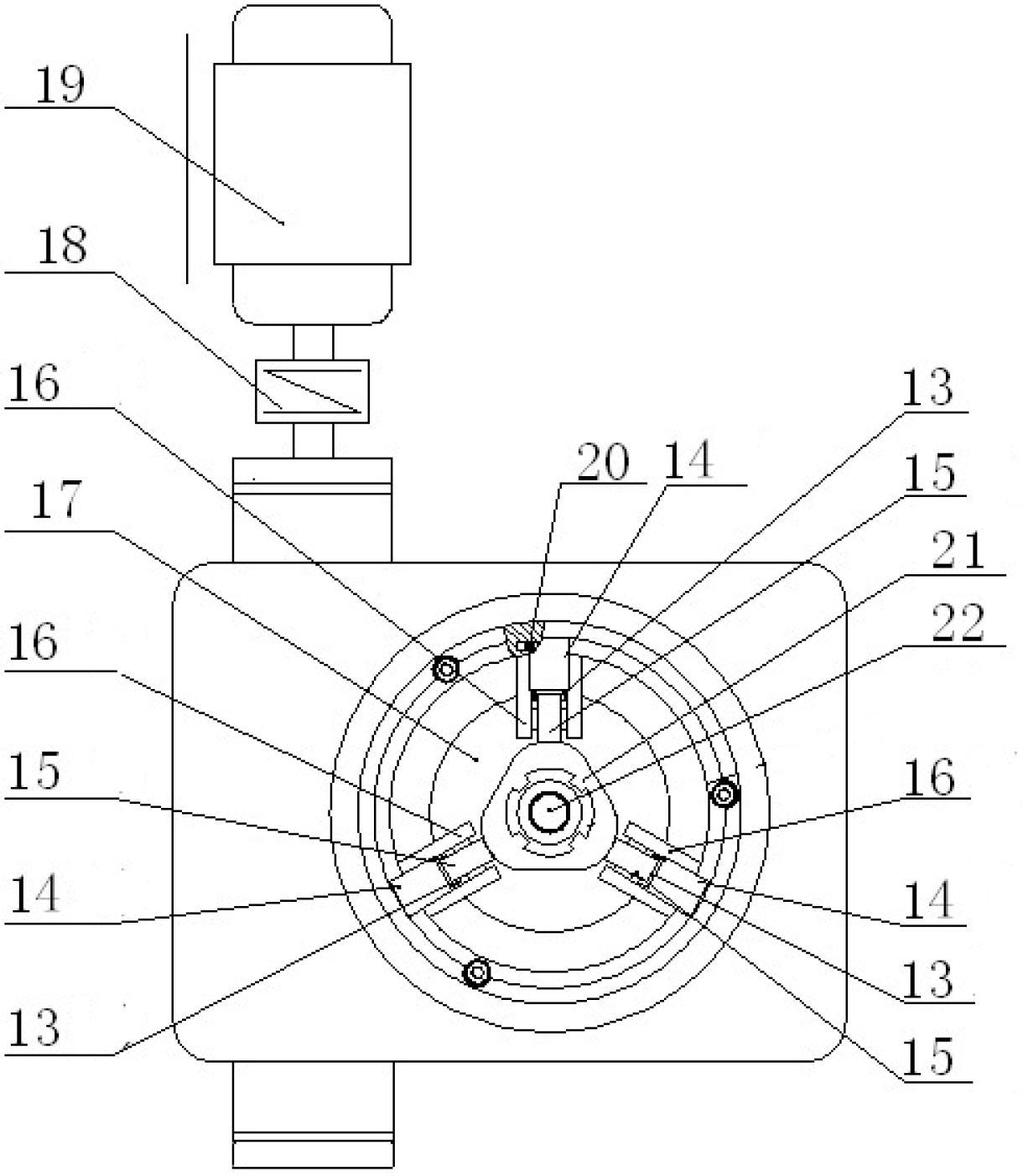

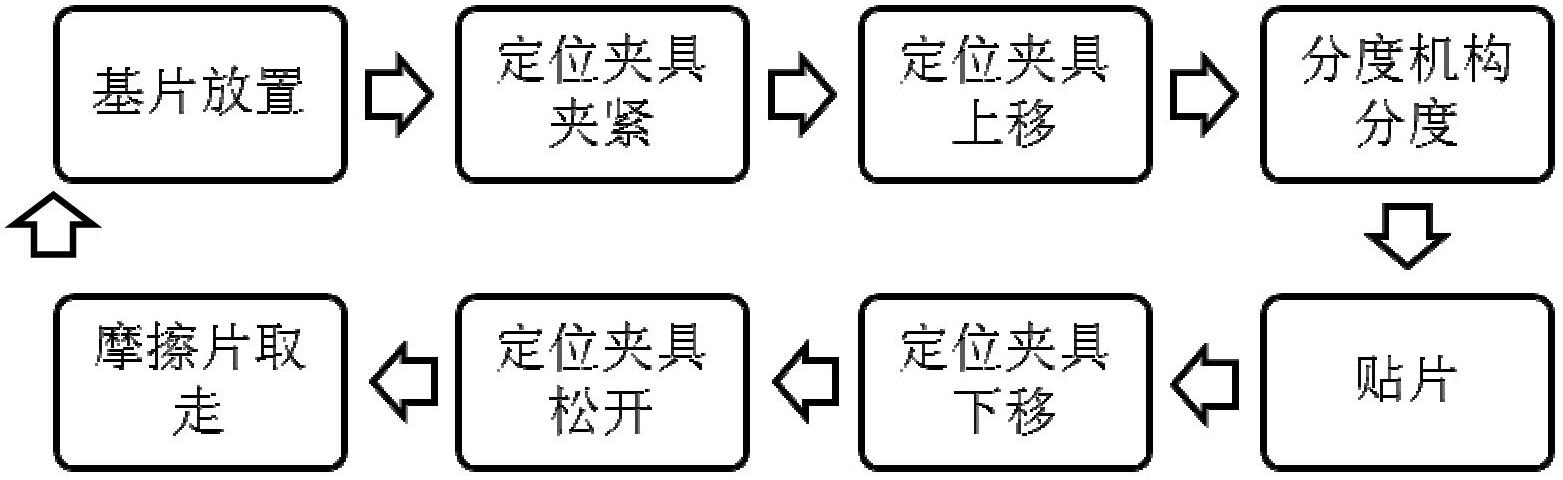

[0018] refer to Figure 1~3 , the indexing and reset device for the paper-based friction plate patch of the present invention includes a reset cylinder 1, a base 2, a worm shaft 3, a worm wheel 4, an upper seat 5, a bearing cover 6, a positioning seat 7, a positioning ring 8, a mandrel 9, and a bearing Washer 10, angular contact ball bearing 11, guide rail block 13, indexing spindle 12, positioning block 14, elastic body 15, moving block 16, cylinder fixing plate 17, coupling 18, servo motor 19, return spring 20, triangular cam 21 and swing cylinder 22.

[0019] Base 2, worm shaft 3, worm wheel 4, upper seat 5, indexing main shaft 12, coupling 18, servo motor 19 form the indexing mechanism of this device. The base 2 has half of the worm shaft 3 mounting hole; the upper base 5 also has half of the worm shaft 3 mounting hole, and the base 2 and the upper base 5 together form the mounting hole of the worm shaft 3; the indexing spindle 12 It is a hollow structure, with a spline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com