Thin film feedback throttling device module, static bearing module and main spindle box module

A hydrostatic bearing and restrictor technology, applied in the directions of bearings, bearing components, shafts and bearings, etc., can solve the problems of inability to achieve integration, many pipelines for restrictors, etc., and achieve the effect of omitting connecting pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

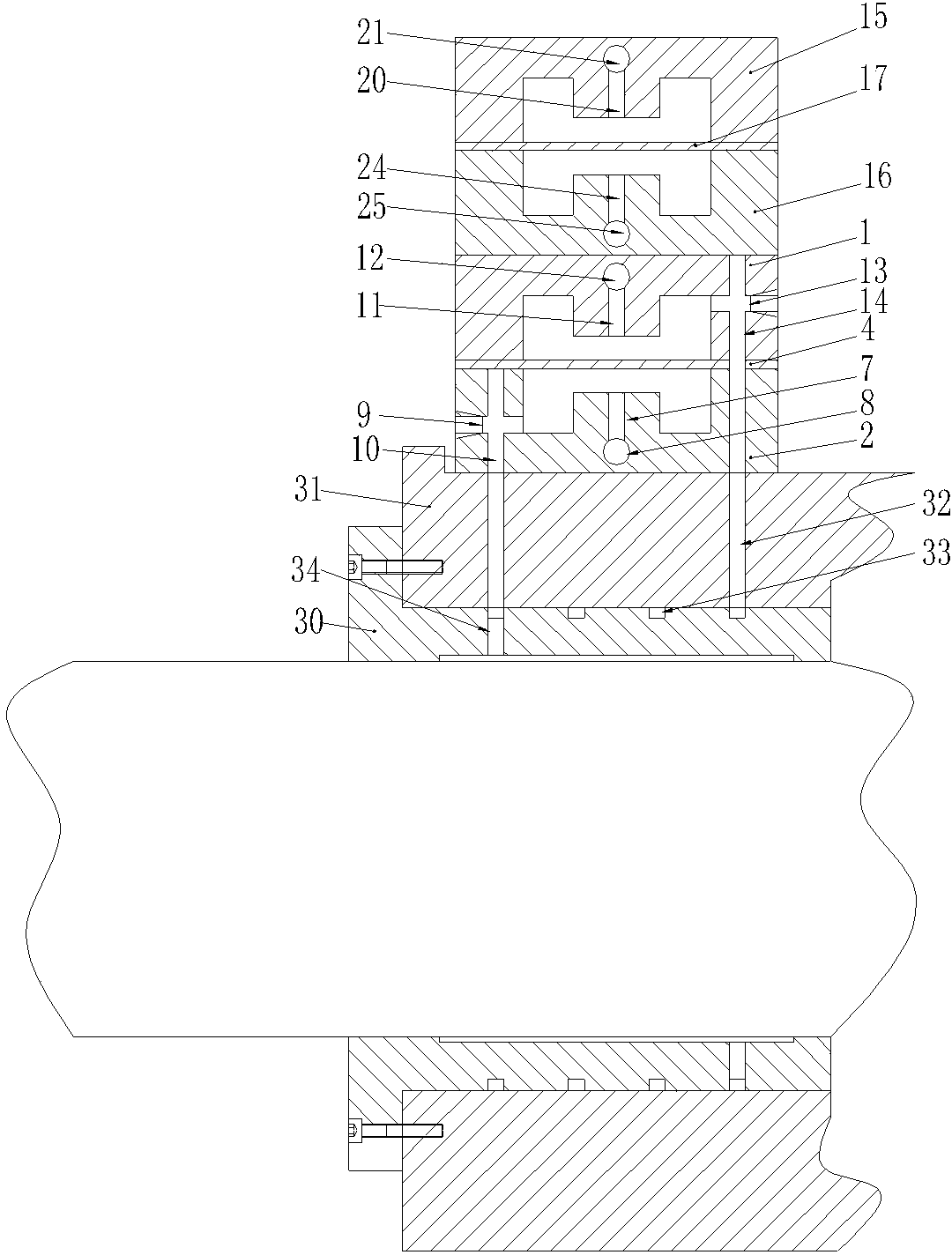

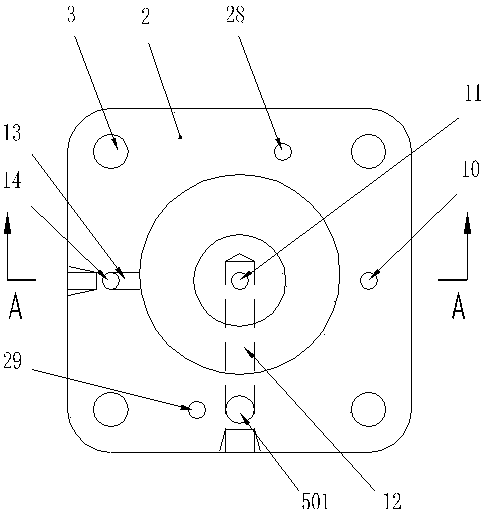

[0047] Example 1 of a thin-film feedback throttle module, such as Figure 1-10 As shown, there is a main restrictor and a bypass restrictor, both of which are film feedback restrictors.

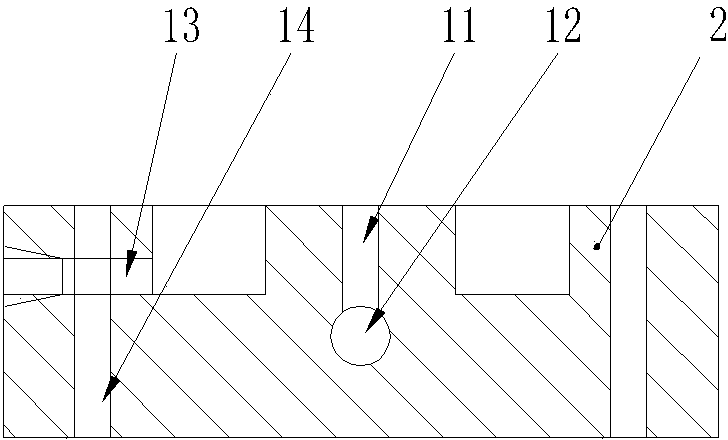

[0048] The main restrictor has a first housing, the first housing is composed of a first upper half shell 1 and a first lower half shell 2 fixedly assembled together, the first upper and lower half shells are respectively provided with corresponding positioning connections hole 3, in addition, the first upper half-shell 1 and the first lower half-shell 2 are all provided with annular grooves on the two opposite sides, and the grooves make the corresponding sides of the first upper and lower half-shells form A circular platform, the height of which is lower than the depth of the groove where it is located, so that the circular platforms on the first upper and lower half-shells are relatively non-contact, a first film 4 is arranged between the first upper and lower half-shells, the second The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com