Multifunctional washing integrated machine and dry cleaning and water washing drying switching method

An all-in-one, multi-functional technology, applied in the field of washing machines, can solve problems such as high cost of use, difficulty in integration, and large size, and achieve the effects of simplifying equipment structure and operating costs, reducing operating costs, and reducing equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

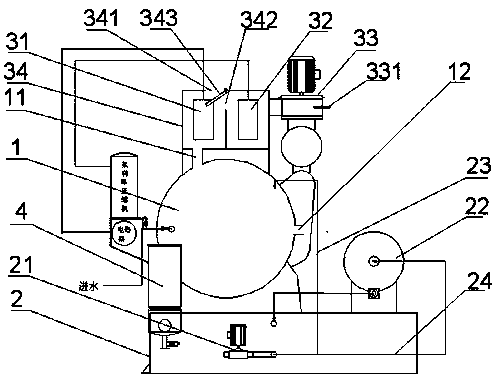

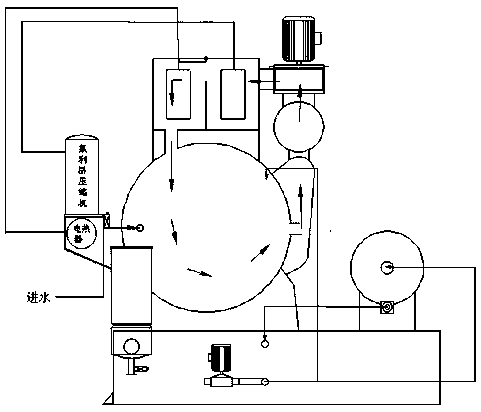

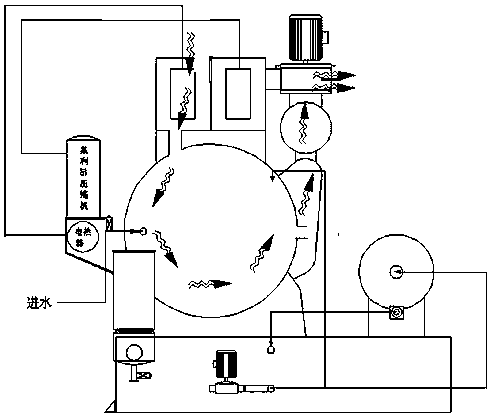

[0023] Such as figure 1 , 2 . As shown in .3, a dry and water washing integrated machine includes a driven drum body 1 installed in the casing, a dry cleaning liquid tank 2, a drying system, and a dry cleaning system.

[0024] The drum body is provided with a water inlet, a drain port, a dry cleaning liquid inlet, a dry cleaning liquid discharge port, a drying air inlet 11, and a drying air outlet 12, and the dry cleaning liquid discharge port communicates with the dry cleaning liquid tank;

[0025] The dry-cleaning system includes a dry-cleaning pump 21 and a dry-cleaning liquid filter device 22. The dry-cleaning pump 21 is installed on the dry-cleaning liquid tank for extracting the dry-cleaning liquid. The liquid outlet of the dry-cleaning pump 21 is provided with a washing branch 23 and a backwashing branch 24. The branch 23 is connected to the dry cleaning liquid inlet of the drum body, the backwash branch 24 is connected to the dry cleaning liquid filter device 22, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com