Liquid crystal display module and liquid crystal display device

A liquid crystal display module and vertical wall technology, which is applied in the direction of lighting devices, lighting auxiliary devices, lighting device components, etc., can solve the problem that the frame of the liquid crystal display module cannot be further narrowed, and achieve the effect of a narrow frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

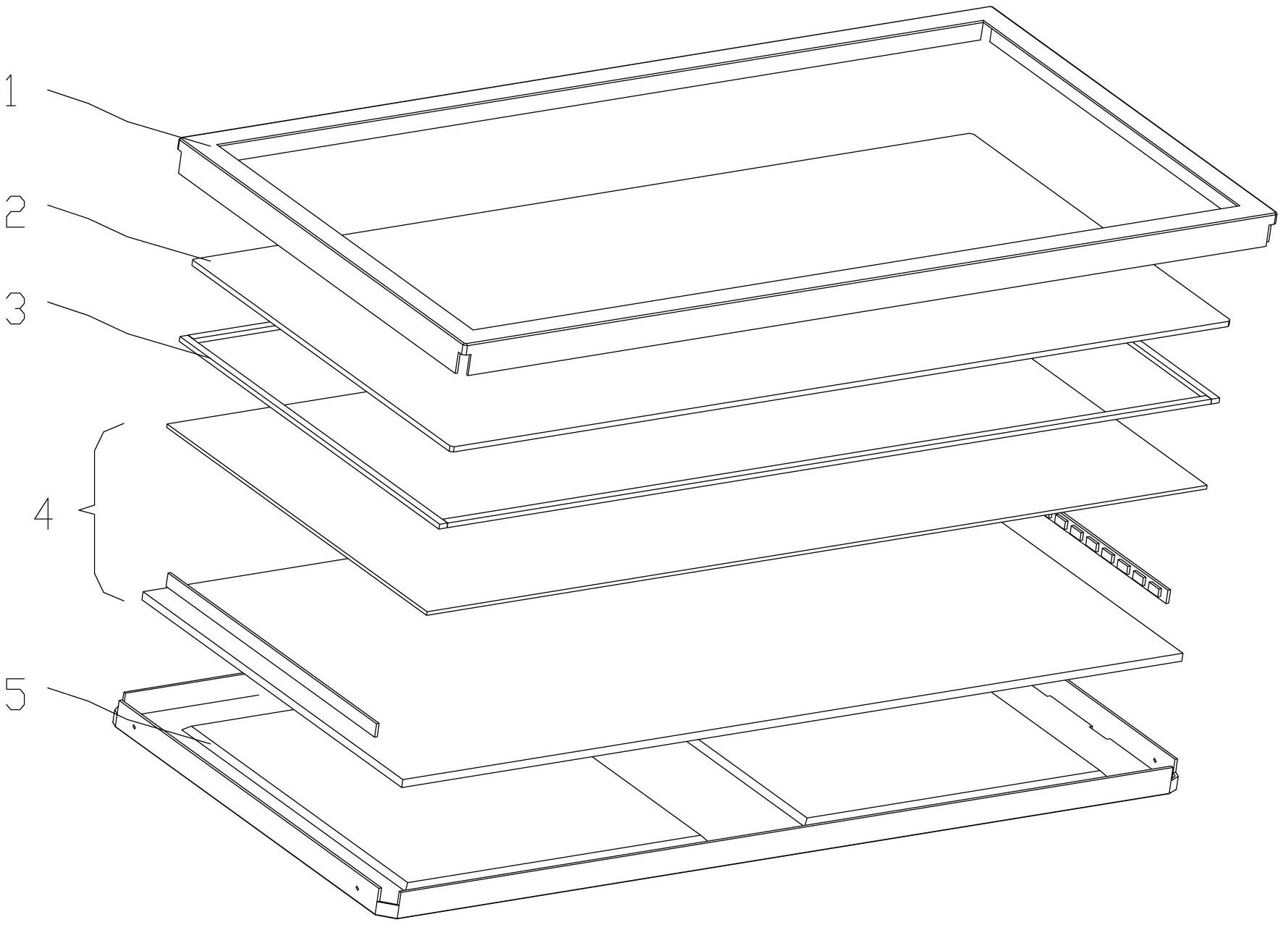

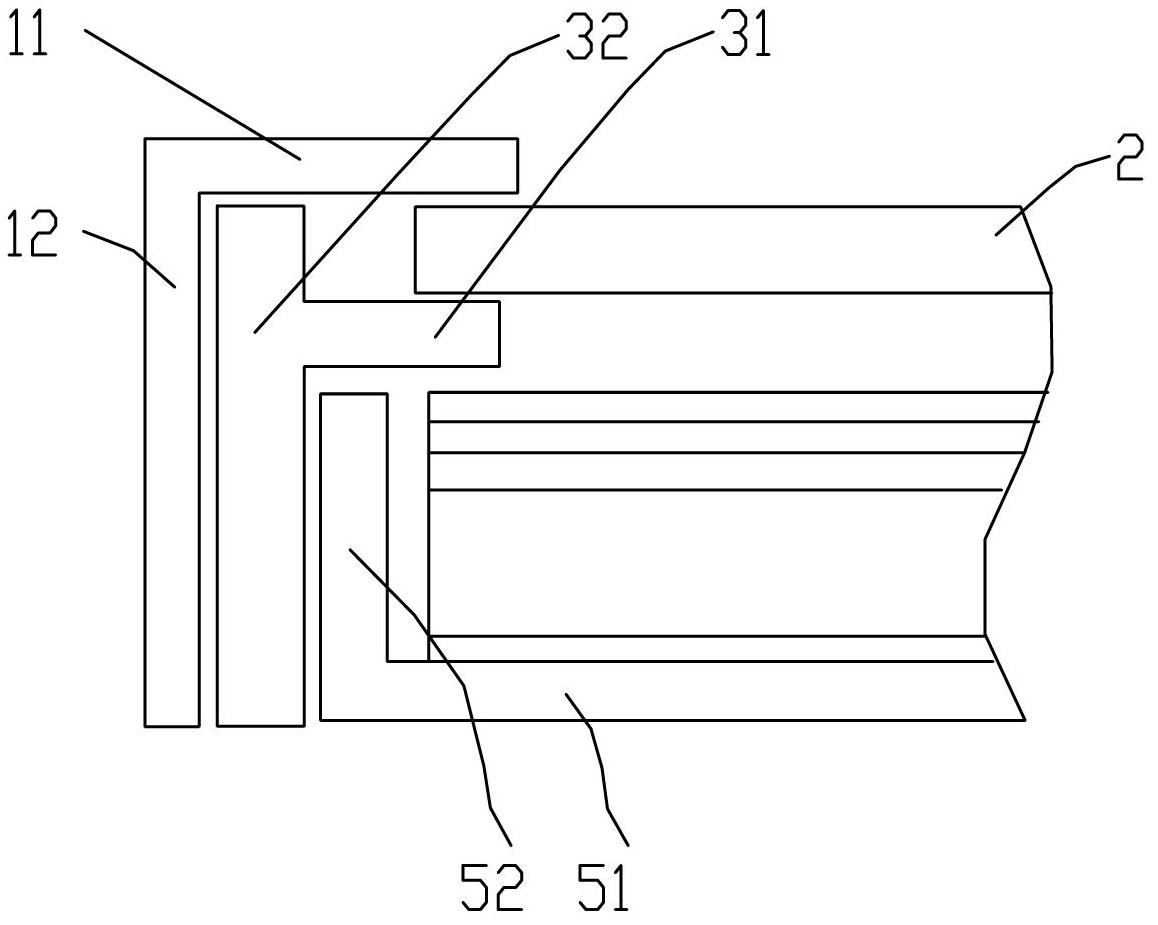

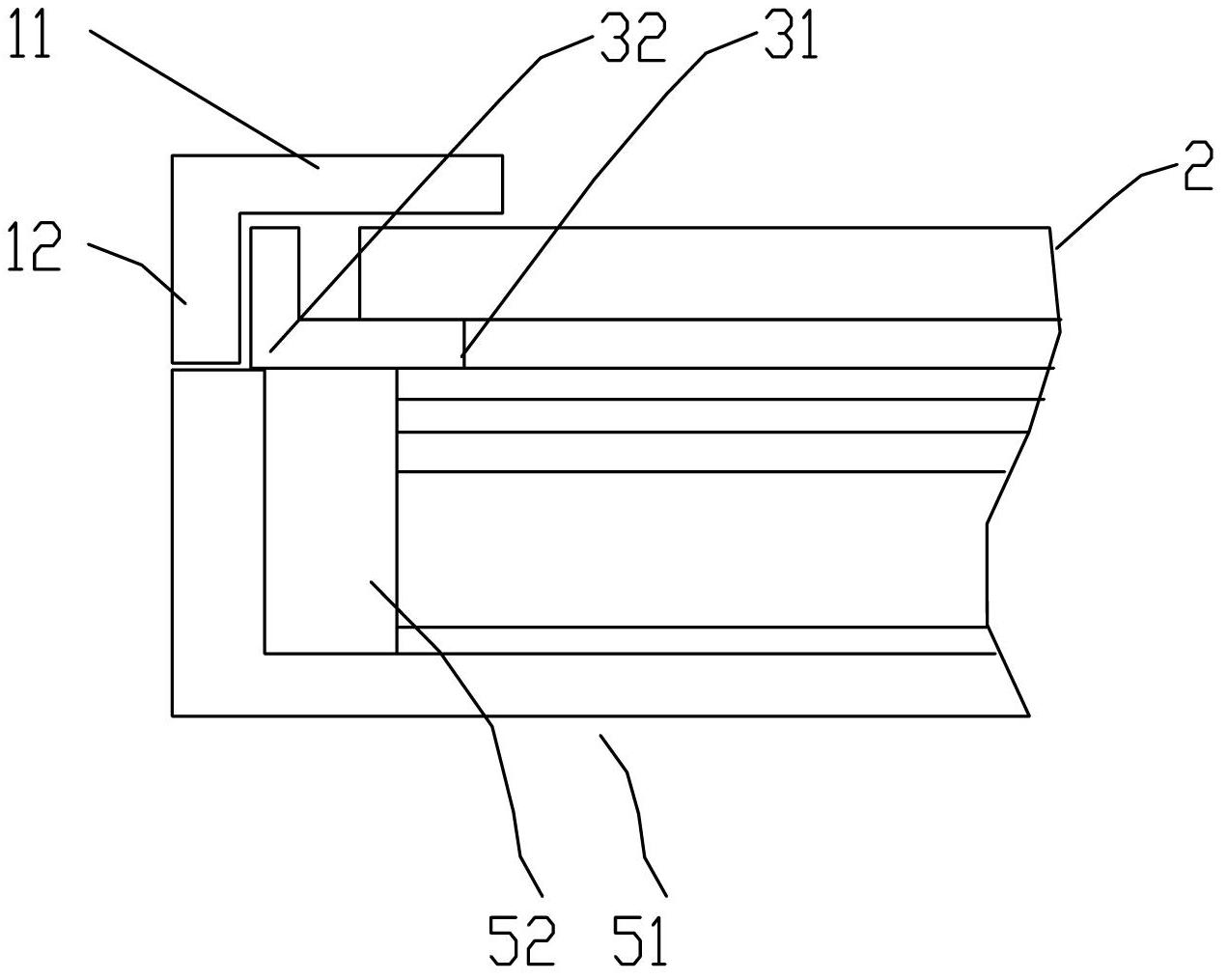

[0028] The present invention discloses a liquid crystal display device, including a liquid crystal display module, as the first embodiment of the liquid crystal display module of the present invention, such as Figures 3 to 9 As shown, it includes a front frame 1 and a back plate 5, the front frame 1 includes a horizontal wall 11 and a vertical wall 12, the back plate 5 also includes a horizontal wall 51 and a vertical wall 52, the front frame 1 The vertical wall 12 of the vertical wall 52 and the vertical wall 52 of the backboard 5 are aligned up and down. In this embodiment, the liquid crystal display module further includes a middle frame 3, and the middle frame 3 includes a horizontal wall 31 and a vertical wall 32, and the vertical wall 32 of the middle frame 3 is positioned vertically between the front frame and the back panel. The inner side of the wall 12,52.

[0029] The liquid crystal display module in the prior art has already made the frame very narrow, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com