A coated substrate, a process for production of a coated substrate, a package and a dispersion coating

A dispersion, coating technology, applied in coating, transportation and packaging, without pigment coating, etc., can solve problems such as reducing bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

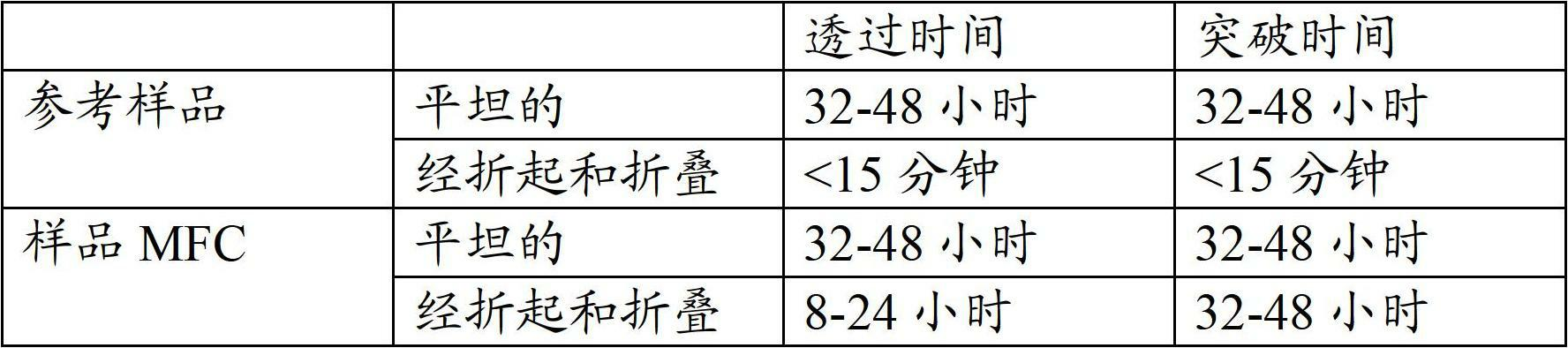

[0042] Use uncoated cardboard as the substrate. The substrates had an areal weight of 210 gsm and a Bendtsen roughness level of 400-500 ml / min.

[0043] The substrates were coated with a commercially available dispersion paint dispersion called Cartaseal TXU manufactured by Clariant (UK), which is a latex based aqueous dispersion. The dispersion was used as a reference, hereinafter referred to as "reference sample", and by mixing microfibrillated cellulose with the dispersion, hereinafter referred to as "sample MFC". MFC was metered into the dispersion for the sample MFC until the Brookfield viscosity was about 1000 mPas.

[0044] Uncoated paperboard was coated by means of a rod coating unit dispersion on the sheet. The weight of the dispersion coating on both samples was 15 gsm.

[0045] The sheet is then dried.

[0046] Microfibrillated cellulose is manufactured in high consistency from bleached pine sulfite pulp. The bleached pulp was firstly pre-mechanically treated i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com