Pressure mounting slip coupling

一种滑动联轴器、压力的技术,应用在滑移联轴器、联轴器、流体驱动离合器等方向,能够解决从动机或原动机破损等问题,达到提供绝缘功能、有效且正确切断、提高耐久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

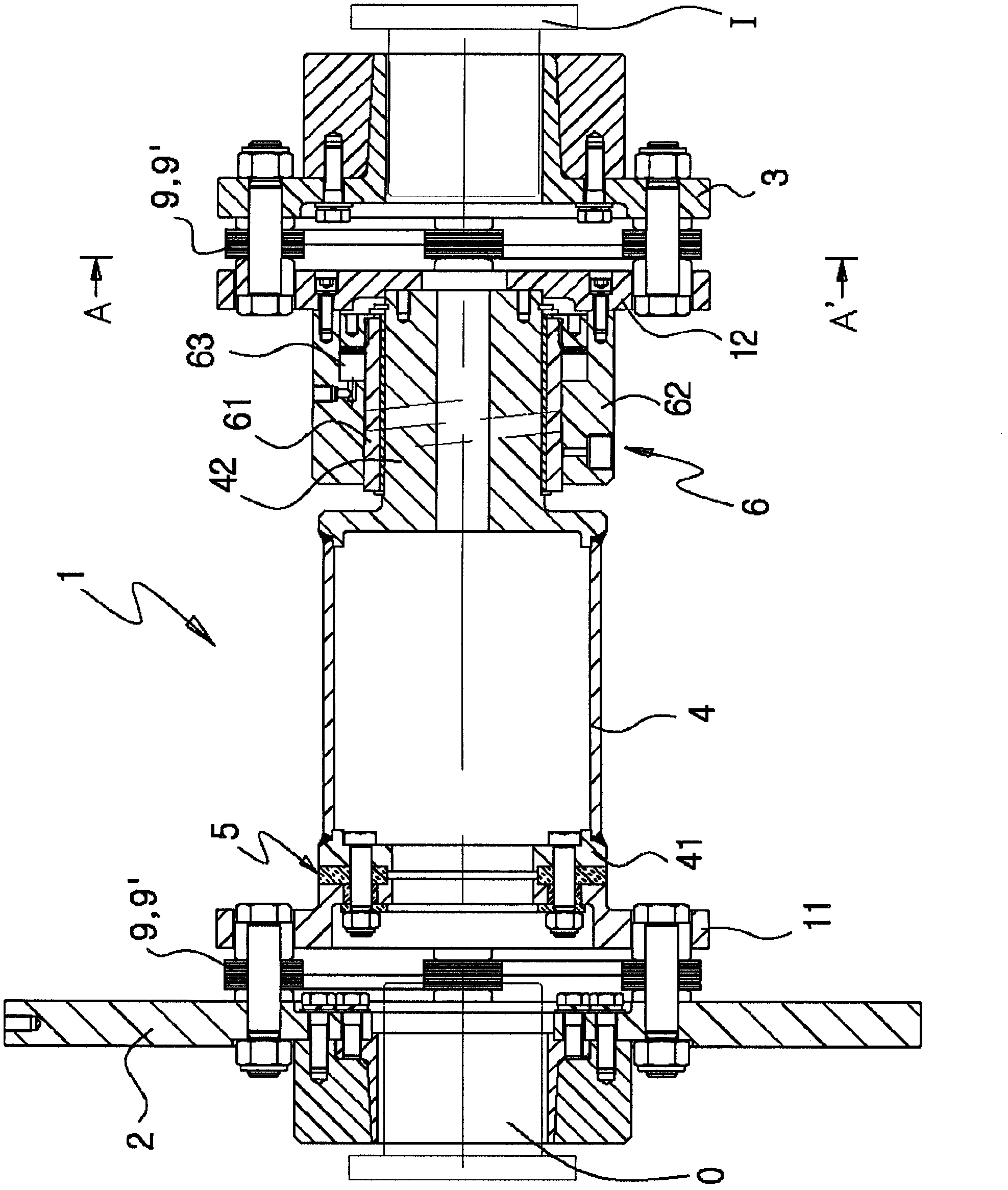

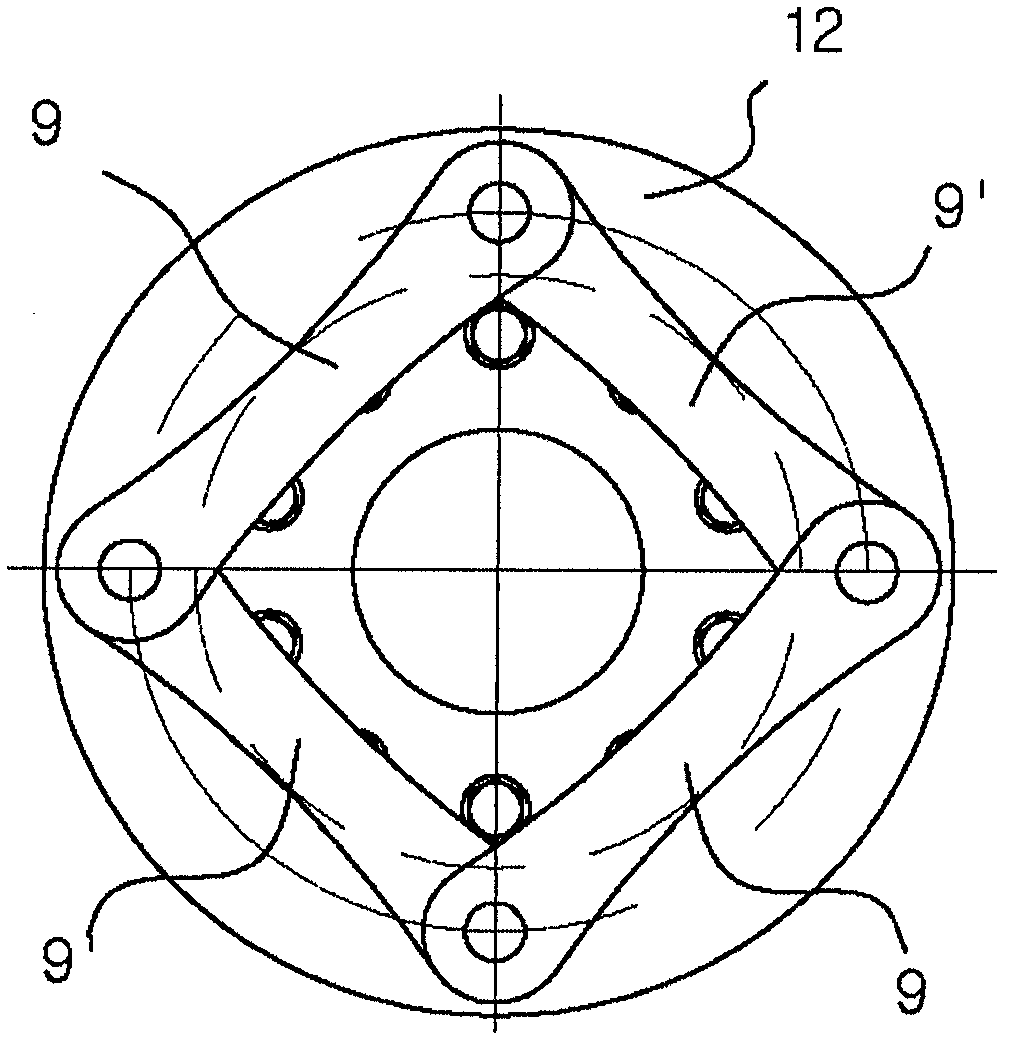

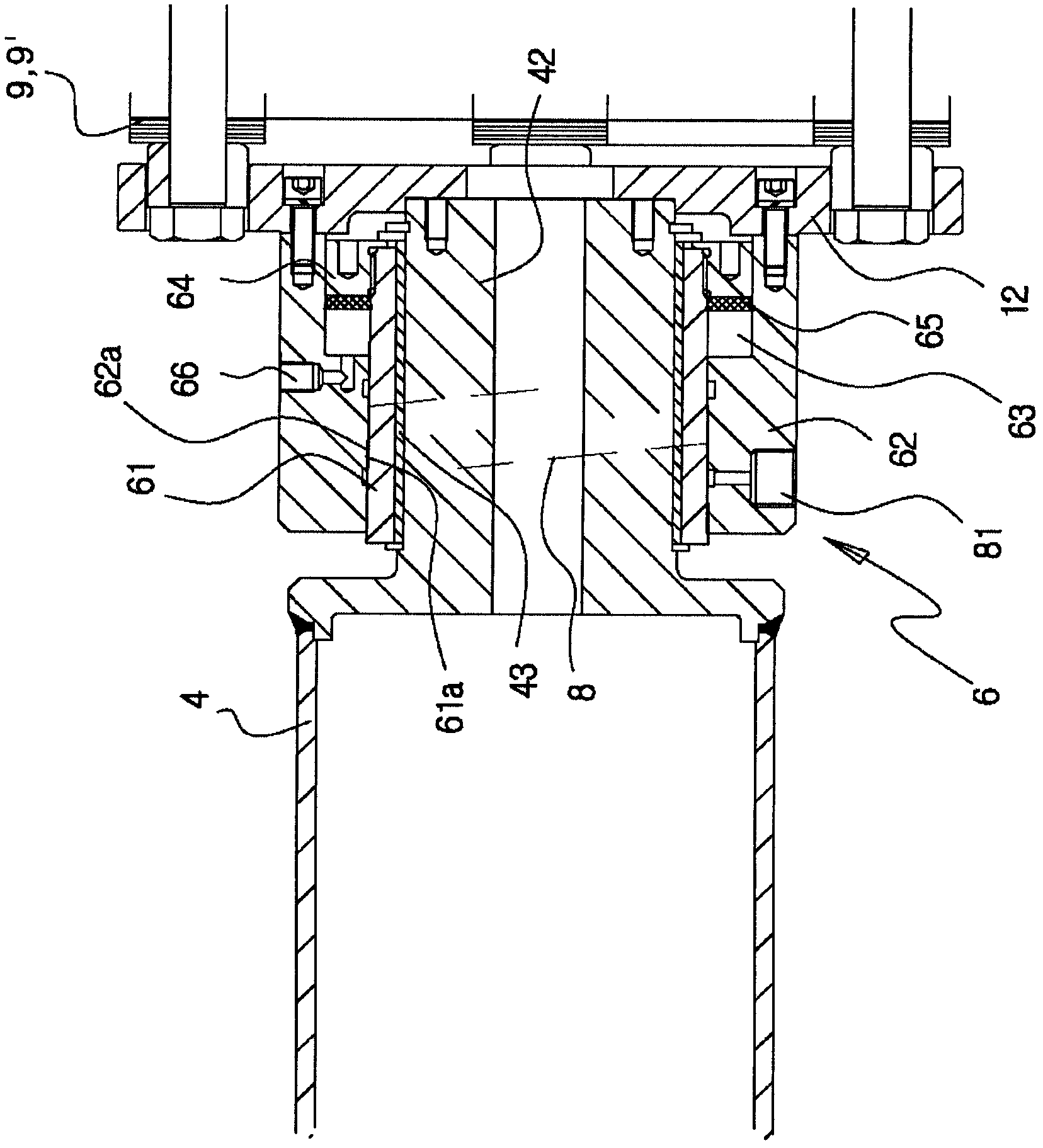

[0051] The present invention constitutes a pressure-mounted sliding coupling that connects the output shaft of the prime mover and the input shaft of the driven machine, and is characterized in that it can transmit eccentricity and deflection in the axial direction when connecting the shafts. Power, and can cut off the overload to prevent the force greater than the predetermined torque from being transmitted to the opposite shaft, and has an insulation function, and can elastically respond to the distance change between the input shaft and the output shaft.

[0052] The coupling of the present invention is structured as follows, that is, an overload prevention part and an insulating part are formed on both sides of the coupling, flanges are formed on both sides of the output shaft connecting the prime mover and the input shaft of the driven machine, and the output shafts are respectively connected. The shaft and the input shaft can transmit power even if there is eccentricity o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap