Combine harvester

A technology for combine harvesters and harvesting devices, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve problems such as heavy burdens, and achieve the effects of reducing loads and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

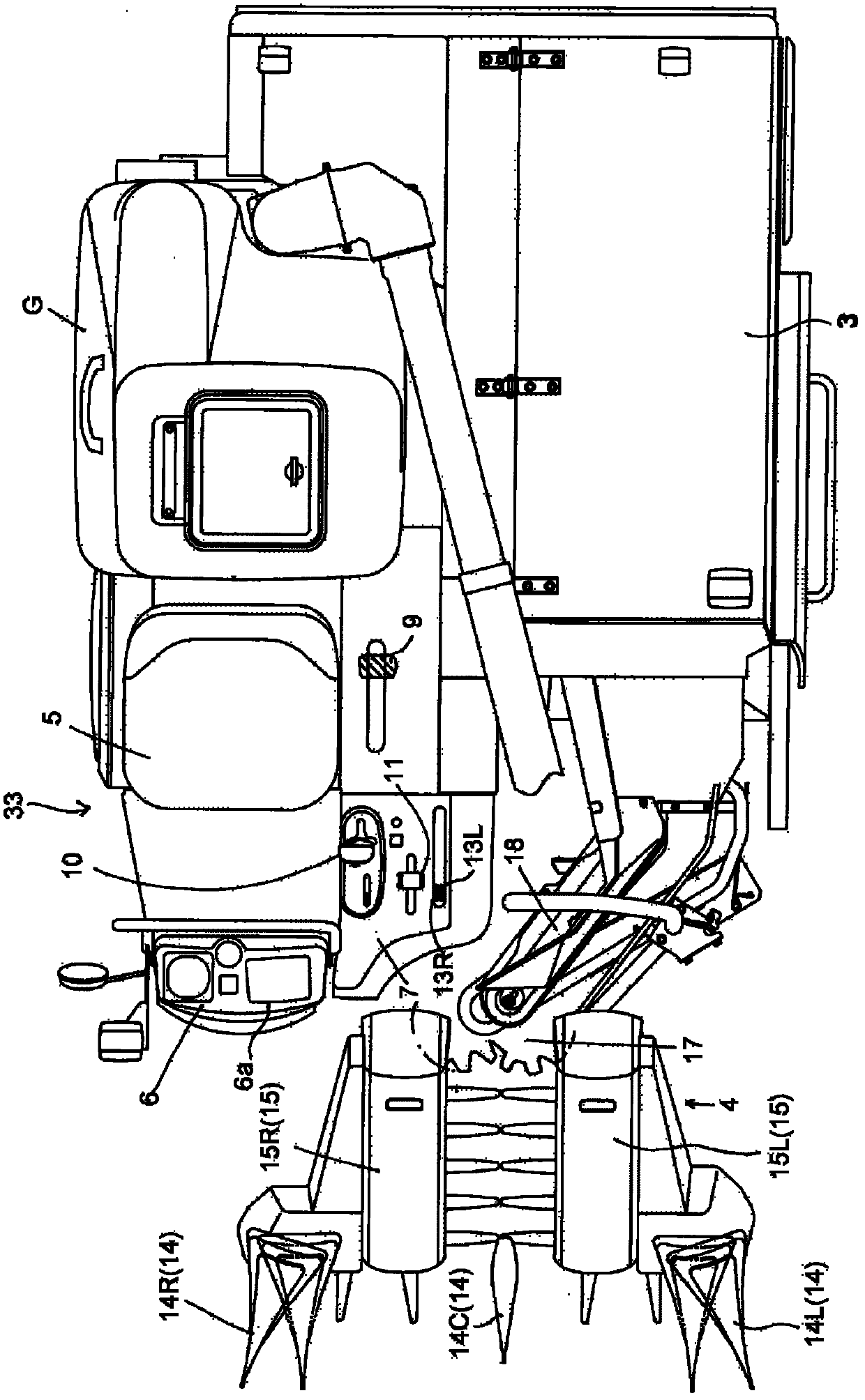

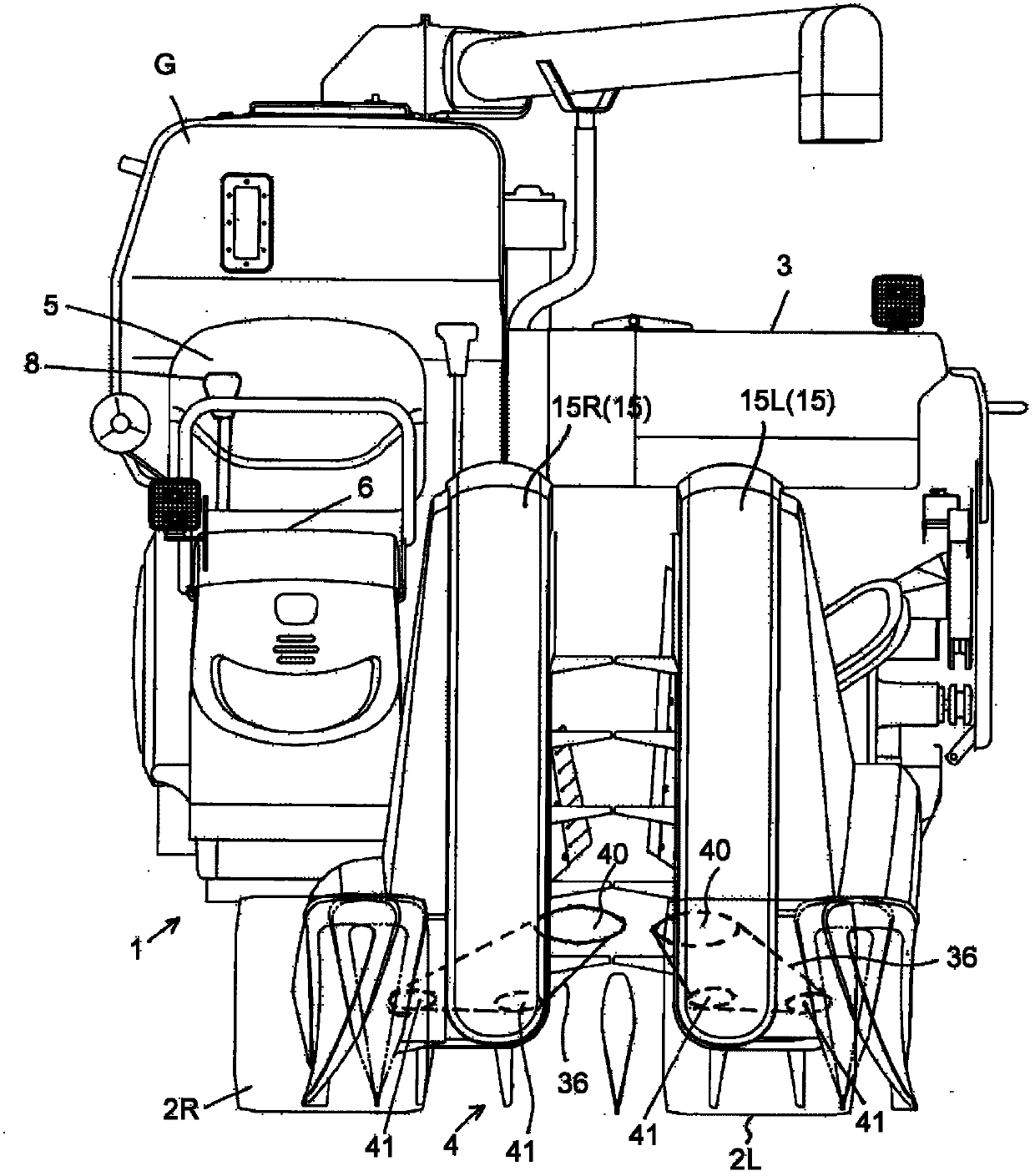

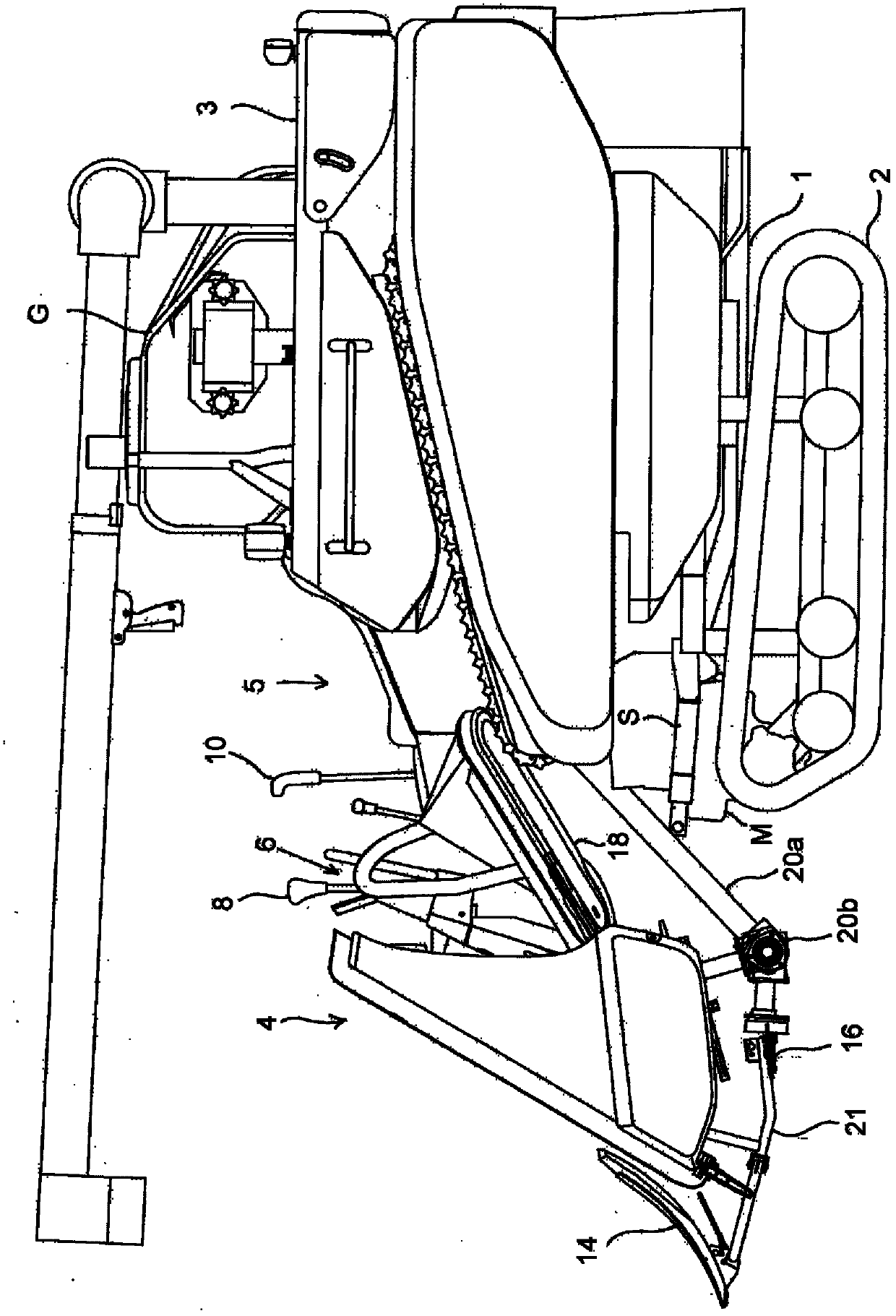

[0062] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0063] In the following description, unless otherwise indicated, the left side when viewed from the operator seated on driver's seat 5 toward the advancing direction of the combine is called left, and the right side is called right.

[0064] Figure 1 ~ Figure 3 It shows the whole figure of the combine harvester, and this traveling body 1 is provided with a pair of left and right traveling crawler belts (crawler belts) 2L, 2R as a traveling device 2 driven via a traveling gearbox M, and a threshing belt mounted on the rear The front portion of the device (threshing section) 3 is provided with a harvesting device 4, and the lateral side of the harvesting device 4 is equipped with a driver's seat 5, a front operation box 6 on the front side of the driver's seat, and a side operation box 7 on the lateral left side of the driver's seat. The operation operation part 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com