Anti-knife-jamming grass chopping mechanism

A grass cutting and anti-jamming technology, which is applied to agricultural machinery and tools, cutting equipment, applications, etc., can solve problems such as easy knife jamming and troublesome cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

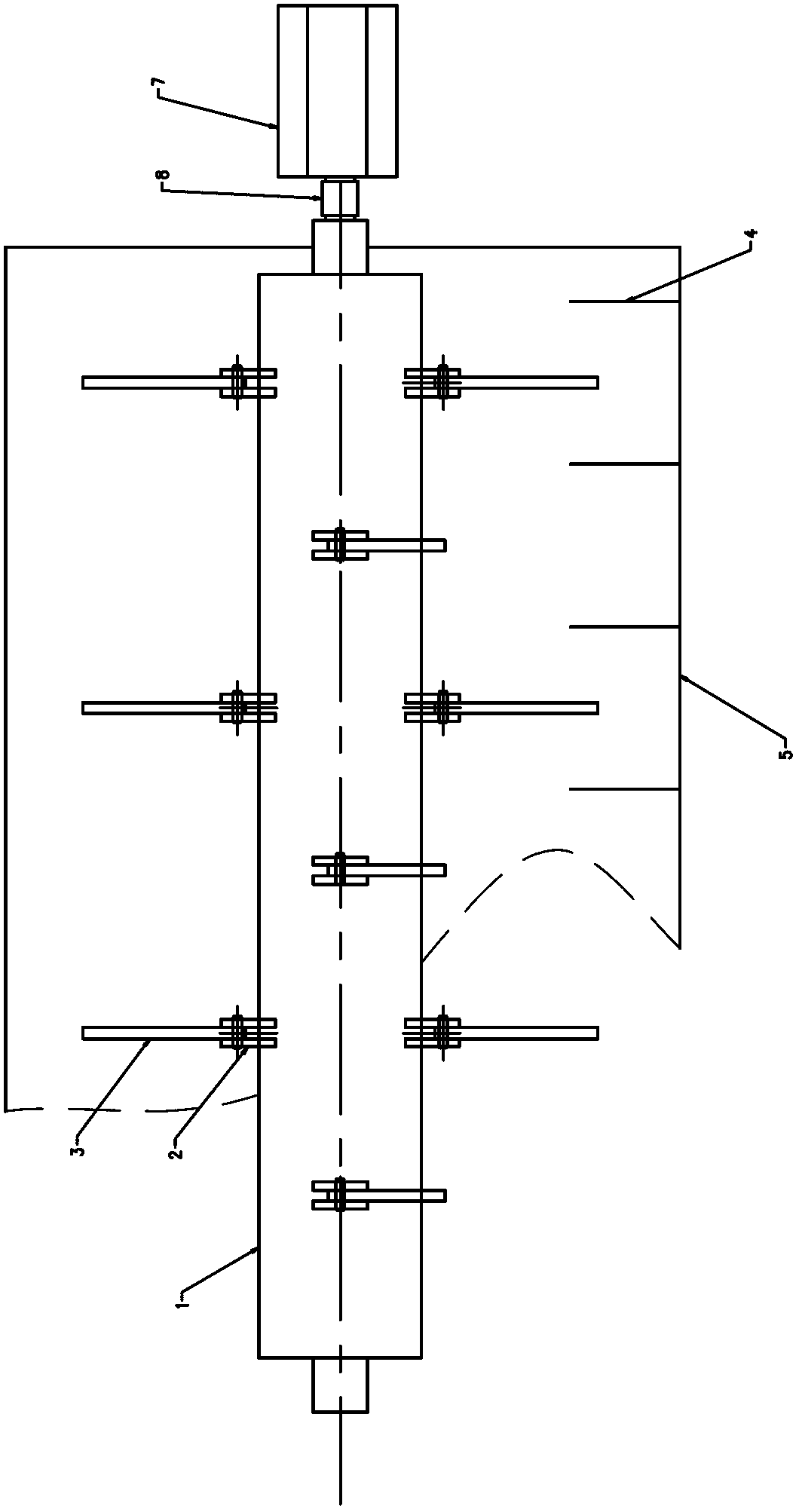

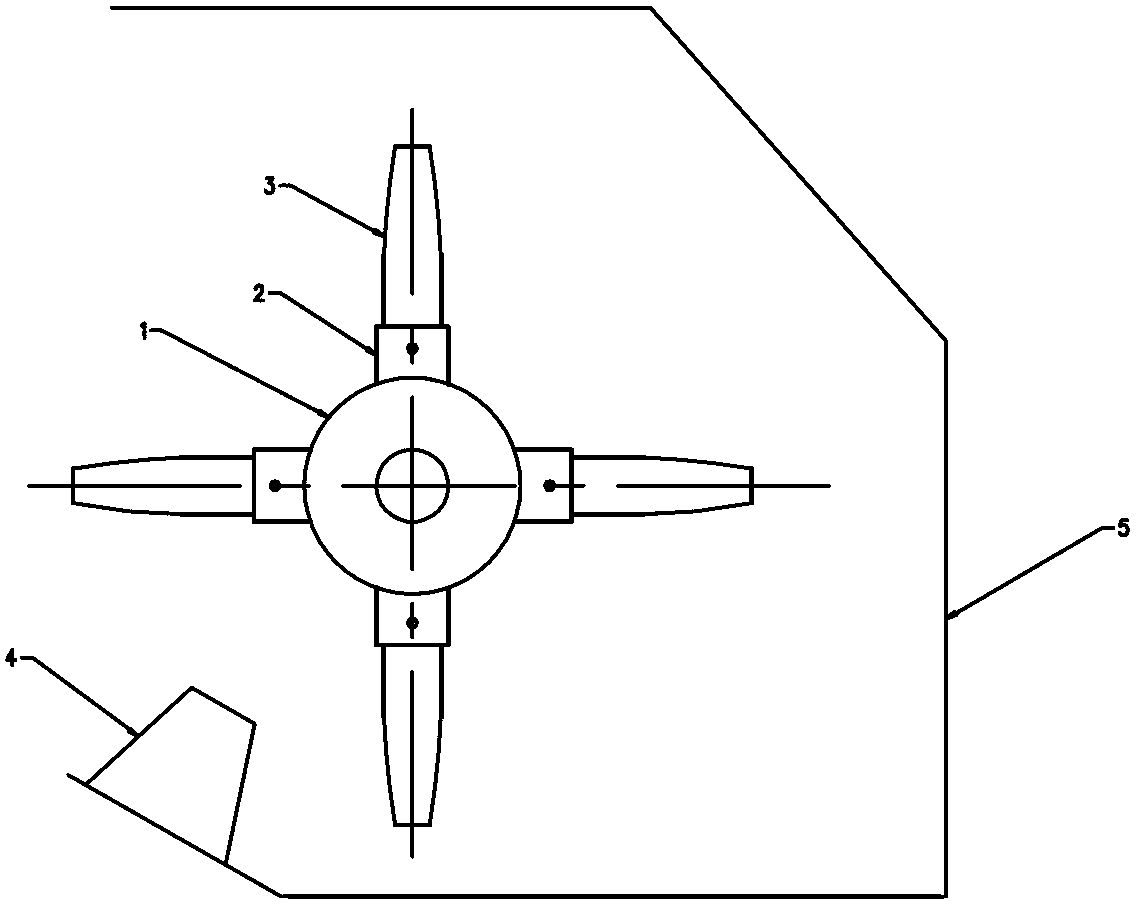

[0019] Such as figure 1 , figure 2 As shown, the present invention is an anti-sticking knife-breaking mechanism, which includes a grass-breaking bin 5 and a knife roller 1. The knife holder 2 is staggeredly distributed on the knife roller. The knife holder is provided with a knife shaft and the knife shaft is provided with For the grass cutter 3, the cutter shaft is rotatably connected with the grass cutter 3, and there is a clearance fit between the grass cutter 3 and the cutter shaft. The knife roller 1 is connected to a driving motor 7, and the output shaft of the driving motor 7 is connected to the knife roller 1 through a shaft coupling 8. A fixed blade 4 is provided on the lower inclined surface of the feeding inlet of the grass-crushing bin, and the fixed blade is located between the grass-crushing knives 3.

[0020] The grass cutter and the knife shaft are connected by a clearance fit. During the rotation of the knife roller driven by the driving mechanism, the grass cut...

Embodiment 2

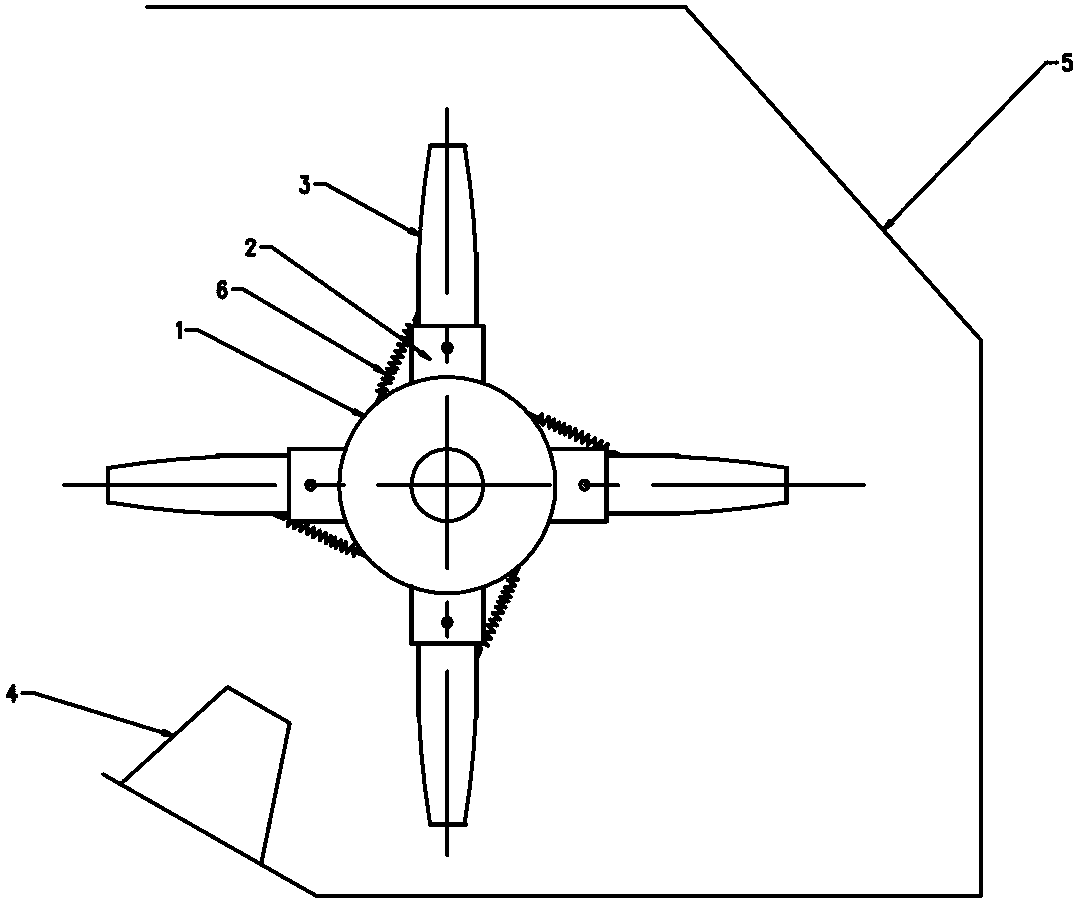

[0023] Such as image 3 As shown, the present invention is an anti-sticking-knife grass-breaking mechanism, which includes a grass-crushing bin 5, a knife roller 1, and grass-crushing knives 3 are distributed on the circumference of the knife roller 1. The output shaft of 7 is connected to the knife roller 1 through a coupling 8. The knife roller 1 is provided with knife holders 2 staggeredly distributed. The knife holder 2 is provided with a knife shaft. The knife shaft is rotatably connected with the grass cutter 3, and there is a clearance fit between the grass cutter and the cutter shaft. The grass cutter is provided with a tension spring 6 on one side in the moving direction, and the other end of the tension spring 6 is connected with the knife roller 1. A fixed blade 4 is provided on the lower inclined surface of the feed inlet of the grass-crushing bin 5, and the fixed blade is located between the grass-crushing knives.

[0024] In this embodiment, when the grass cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com