Pulse reverse blowing ash removal device of ceramic filter

A ceramic filter, pulse backflushing technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of increasing dust concentration, unfavorable long-term stable operation of the filter, affecting the production process, etc. Achieve the effect of reducing the possibility of fracture failure, conducive to long-term stable operation, and easy backflushing parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

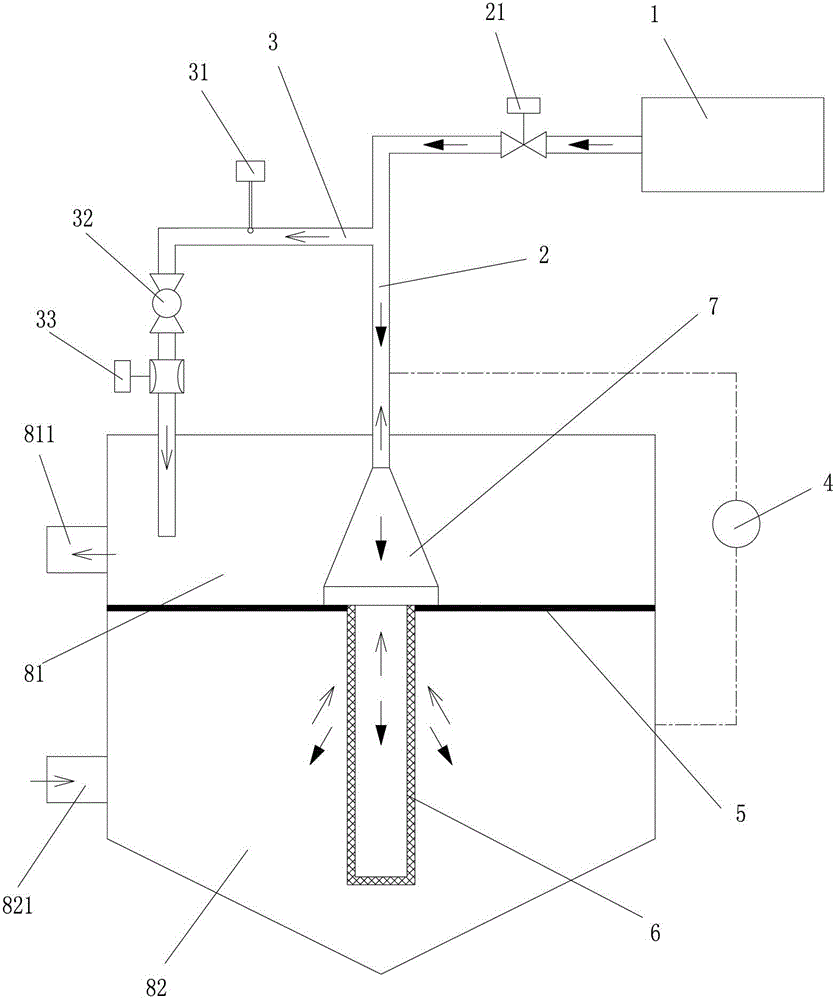

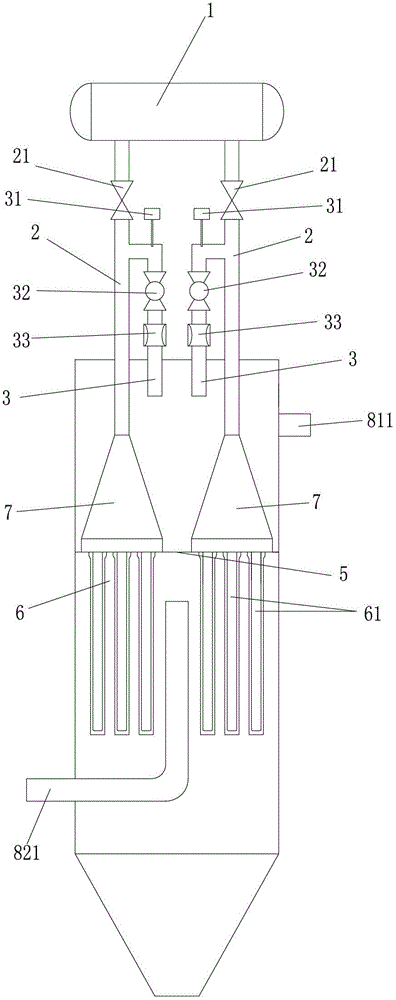

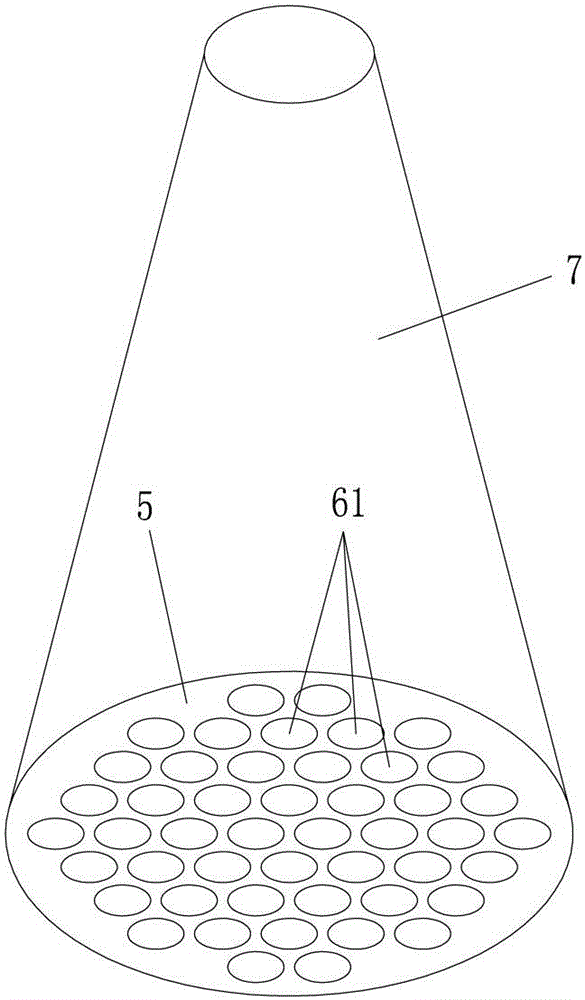

[0028] like figure 1As shown, the present invention proposes a pulse blowback soot cleaning device for a ceramic filter, a filter unit 6 is provided on the tube plate 5 of the ceramic filter, and a gas collection chamber 7 is provided on the filter unit 6 top; the filter tube plate 5 The filter is sealed and separated into an upper clean gas chamber 81 and a lower dusty gas chamber 82, the clean gas chamber 81 is provided with a gas outlet 811, and the dusty gas chamber 82 is provided with a gas inlet 821 The pulse blowback soot cleaning device includes a blowback gas storage tank 1, and the blowback gas storage tank 1 is provided with a blowback pipeline 2 that is sealed and connected with the top of the air collection chamber 7 of the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com