Axle box device, bearing unit and sealing cover

A sealing cover and bearing technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve problems such as stop pin breakage, anti-rotation mechanism failure, etc., and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

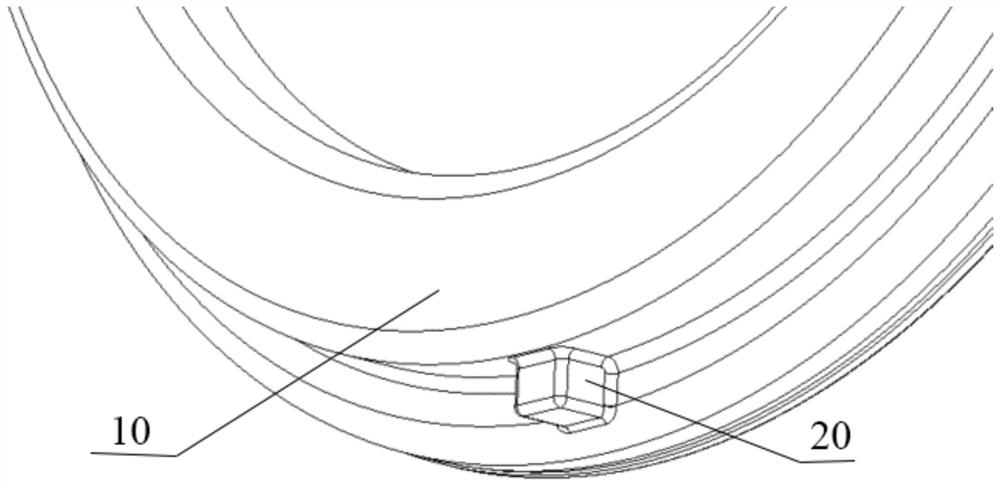

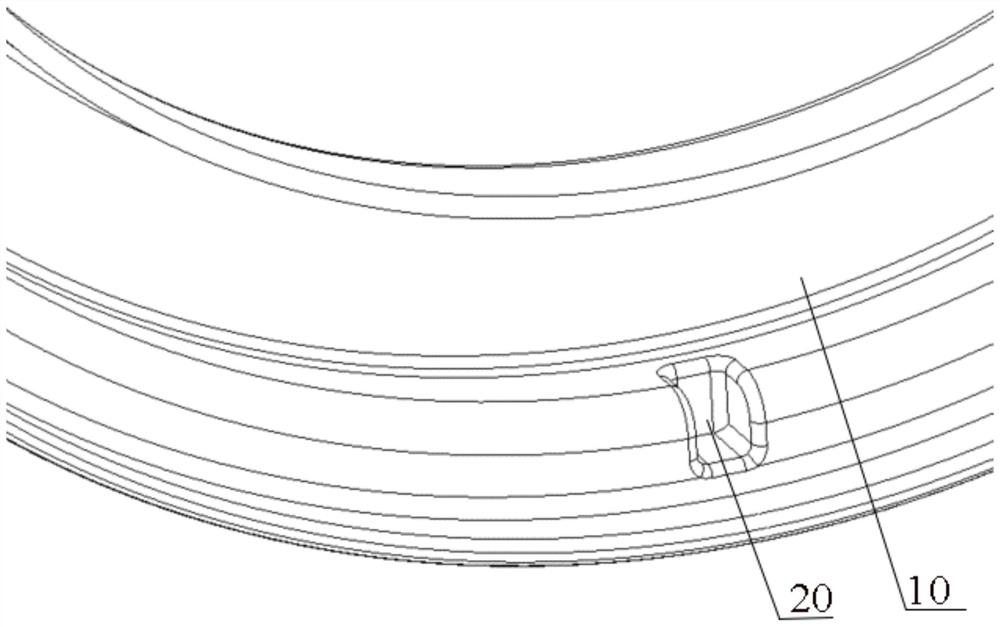

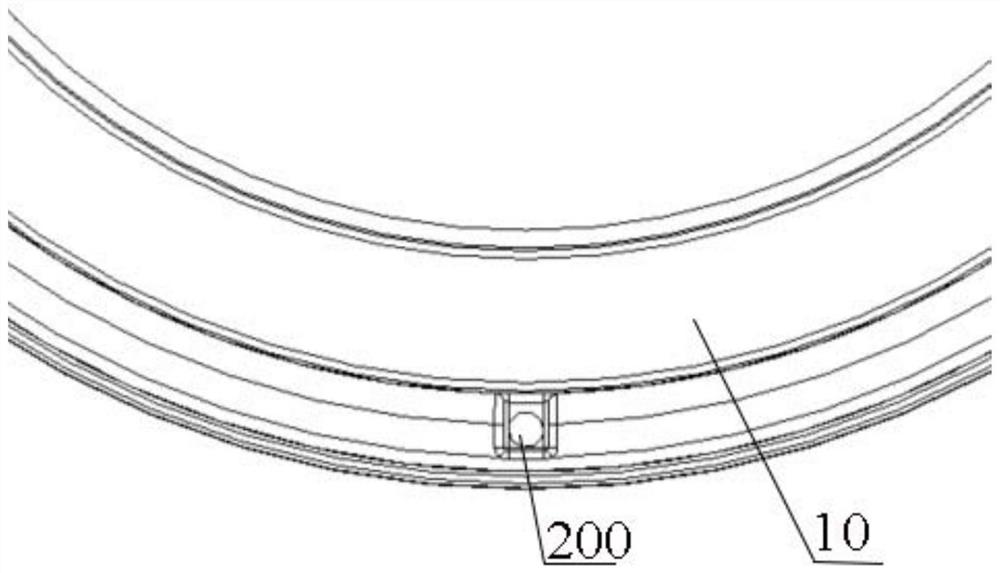

[0028] It can be seen from the background art that the stop pin of the sealing cover is very easy to break during operation, which leads to the failure of the anti-rotation mechanism between the axle box and the sealing cover.

[0029] In order to reduce the possibility of breakage of the stop pin caused by the relative rotation of the axle box cover and the outer ring of the bearing during the operation of the axle box device, the embodiment of the present invention provides a sealing cover. When the sealing cover is working, the stop protrusion The out part cooperates with the stop concave part of the axle box cover of the axle box device, which can prevent the relative movement between the seal cover and the axle box cover along the circumferential direction of the seal cover, because the stop protrusion It is integrally formed with the sealing cover body, so there is no interface between the stop stamping part and the sealing cover body, and the strength of the stop protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com