Fan-out chip packaging structure and packaging method

A chip packaging structure and chip packaging technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of low reliability of packaging structure, stress fracture failure, etc. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

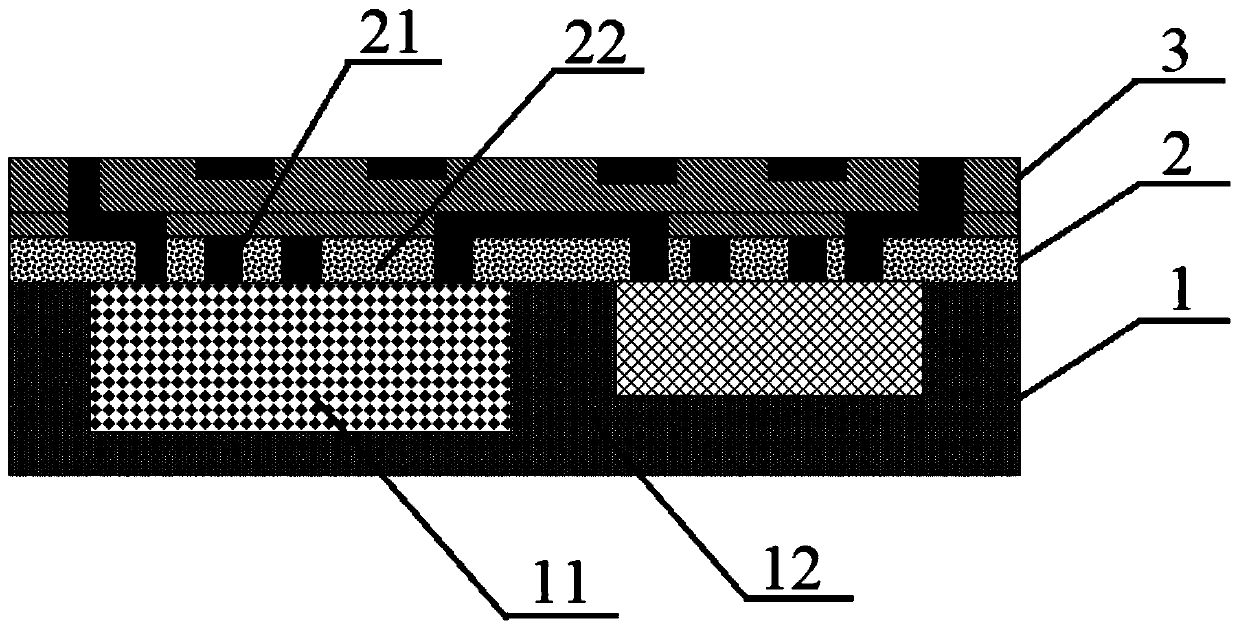

[0030] This embodiment provides a fan-out chip packaging structure, such as figure 1 As shown, the packaging structure includes: a plastic package body 1 , an interconnection layer 2 and a redistribution layer 3 .

[0031] Such as figure 1 As shown, at least one chip 11 is packaged inside the plastic package 1 , and the device surface of the chip 11 is exposed outside the plastic package 1 . Here, the device surface of the chip 11 refers to the surface where the pads of the chip 11 are located. Specifically, the chip 11 can be first mounted on the substrate 4 according to the direction that the device surface of the chip 11 faces the substrate 4, and then mounted on the substrate 4. The molding compound is injected to form the molding layer 12 that encapsulates five surfaces of the chip 11 except the device surface, and then the molding layer 12 and the chip 11 are peeled off from the substrate 4 to form the molding body 1 .

[0032] Such as figure 1 As shown, the interconn...

Embodiment 2

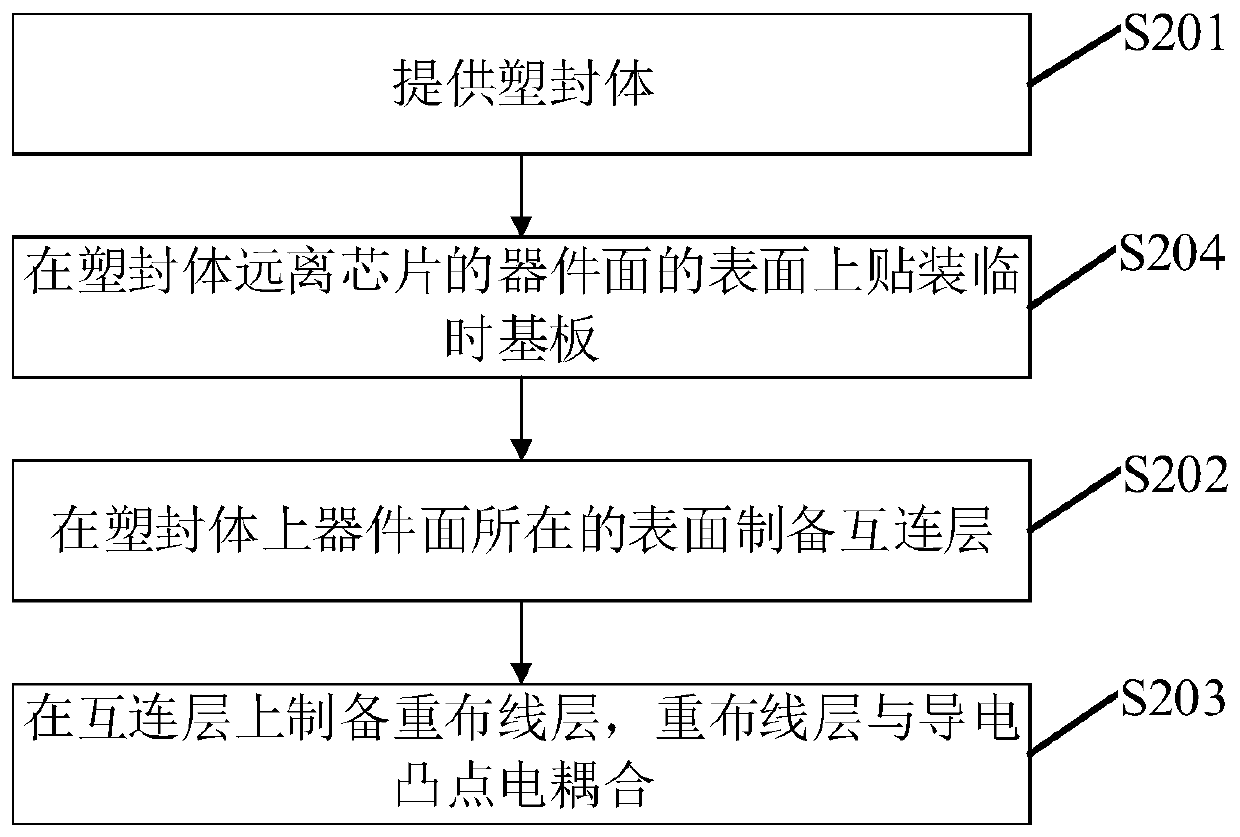

[0040] This embodiment provides a fan-out chip packaging method, and the packaging structure in Embodiment 1 can be prepared according to the method and its preferred implementation, and what has been explained will not be repeated.

[0041] The fan-out chip packaging method provided in this embodiment, such as figure 2 shown, including the following steps:

[0042] S201: Provide a plastic package.

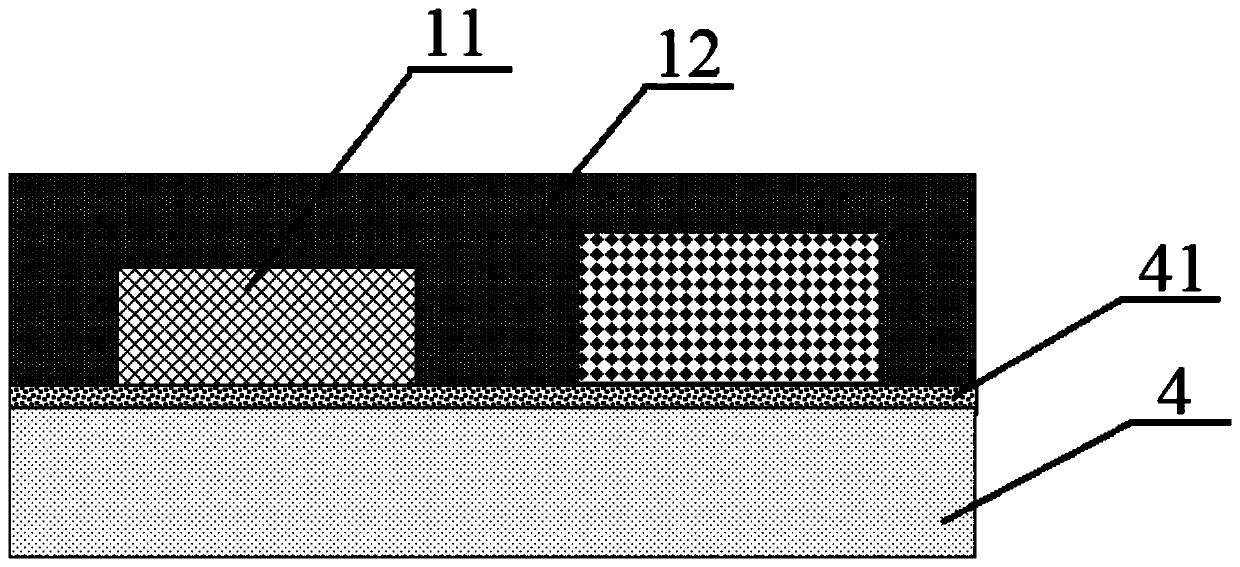

[0043] here, as image 3 As shown, at least one chip 11 is packaged inside the plastic package 1 , and the device surface of the chip 11 is exposed outside the plastic package 1 .

[0044] Specifically, such as image 3 As shown, the plastic package 1 can be prepared by the following steps:

[0045] Step A1: pasting a first temporary bonding glue 41 on a substrate 4 .

[0046] Step A2: paste the chip 11 on the first temporary bonding glue 41 according to the direction that the device surface of the chip 11 faces the first temporary bonding glue 41 .

[0047] Step A3: dispos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com