Special equipment for rapidly cleaning insulator of electrified railway

A technology for electrified railways and special equipment, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve maintenance workers' time-consuming and labor-intensive climbing operations, high labor intensity and danger, and difficulty in finding suitable water sources and other problems, to achieve the effect of compact structure, smooth sliding, and preventing random rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Example A special equipment for rapid cleaning of electrified railway insulators

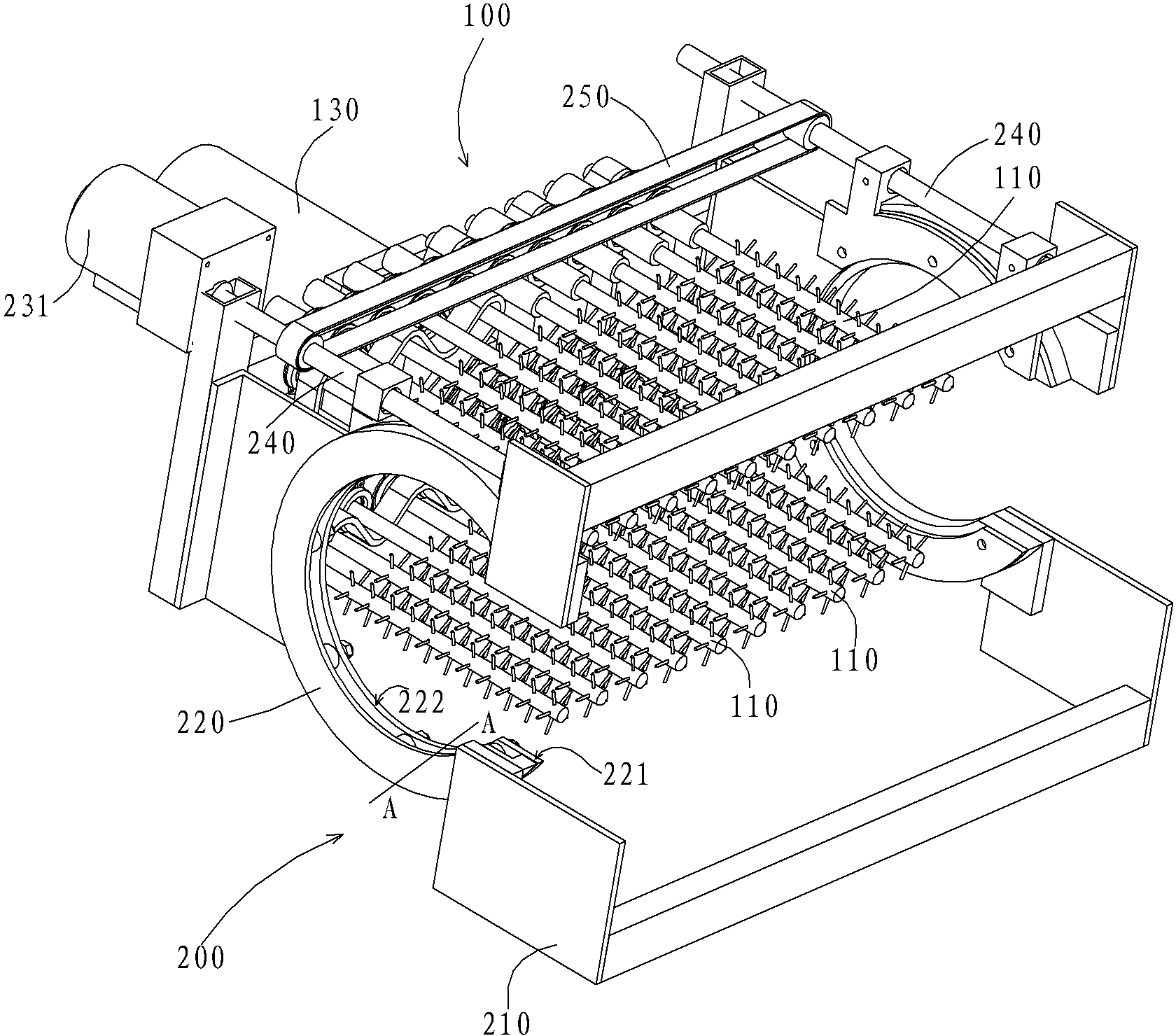

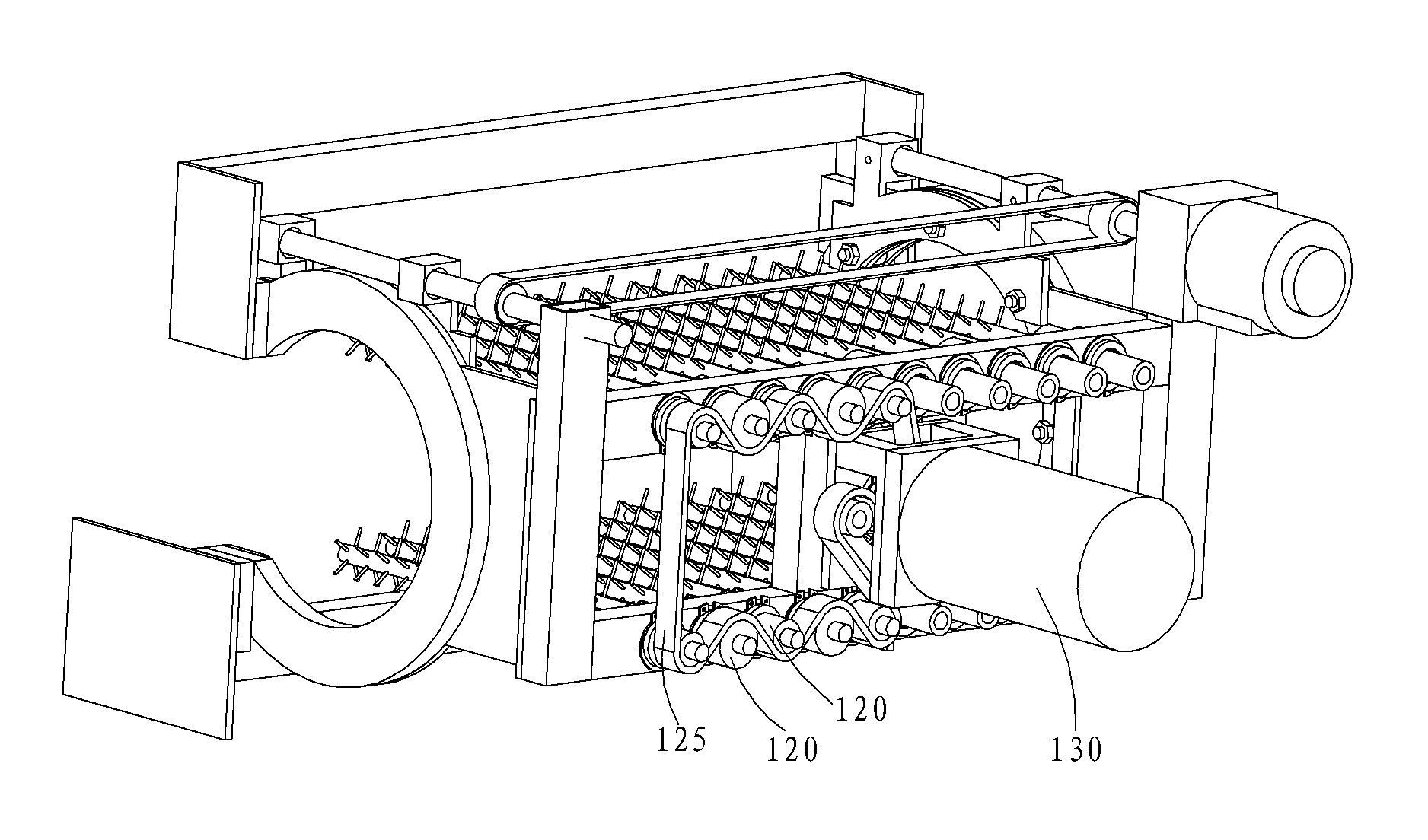

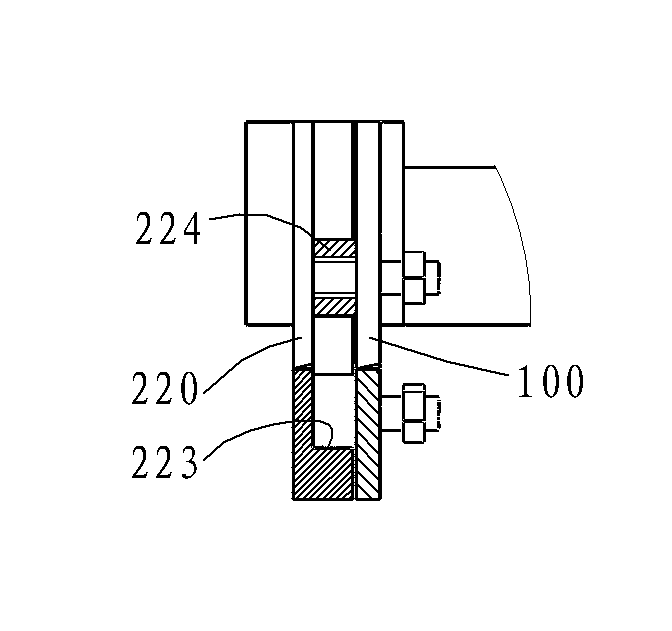

[0035] like figure 1 and figure 2 As shown, the special equipment for rapid cleaning of electrified railway insulators in this embodiment includes two parts: a brush head 100 and a drive part 200 .

[0036] The brush head 100 is provided with a plurality of cylindrical brushes 110 that can be inserted between two adjacent different umbrella leaves of the insulator, and these brushes 110 rotate around their own axes to wipe the umbrella leaves. The driving part 200 drives the brush head 100 to move along the axis of the insulator, so that the brush 110 can achieve a compound motion of rotating around itself and around the insulator, thereby cleaning the entire circumference of the umbrella leaf of the insulator. Since there are multiple brushes 110, these brushes 110 wipe multiple umbrella leaves at the same time, so that the device has a very high cleaning speed.

[0037] The brushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com