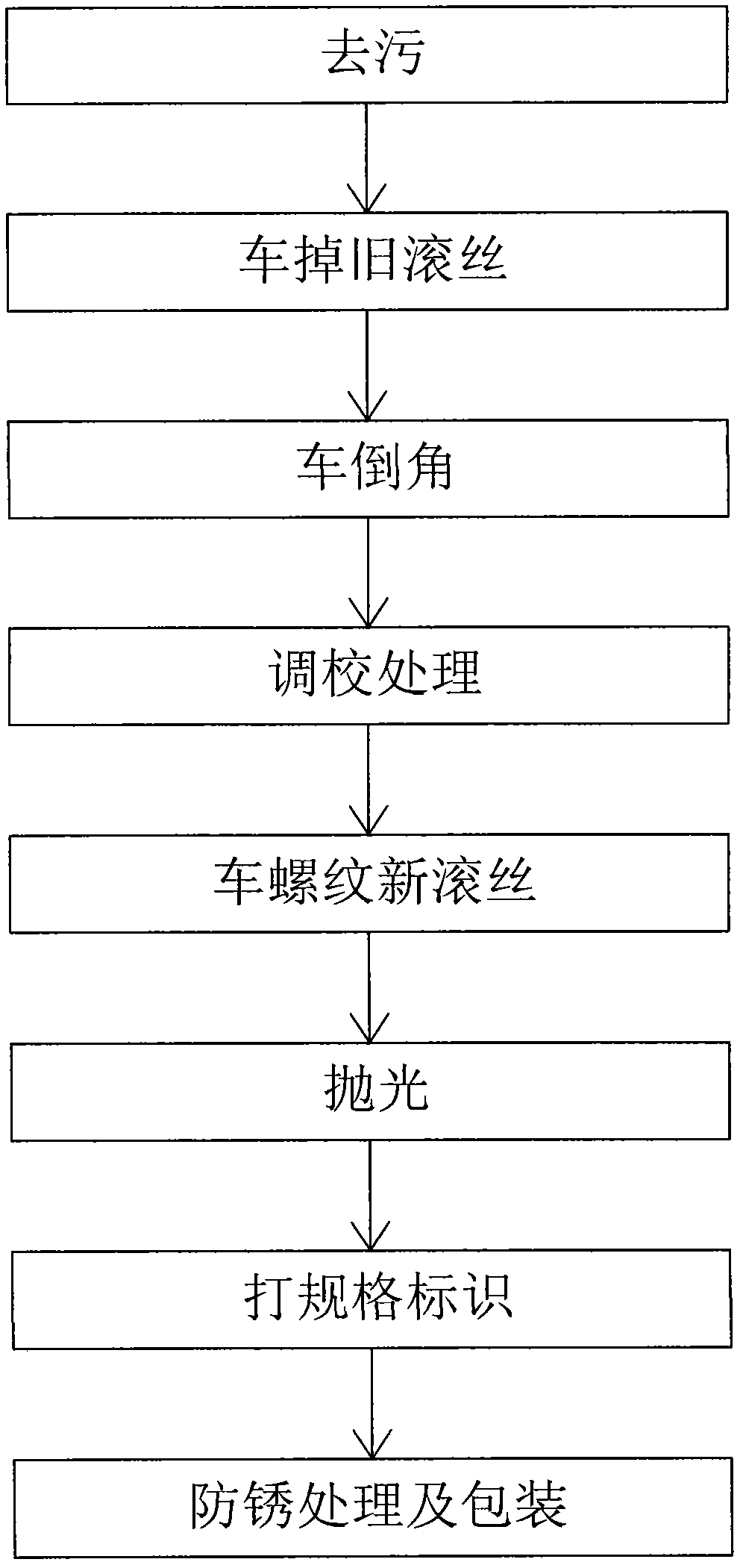

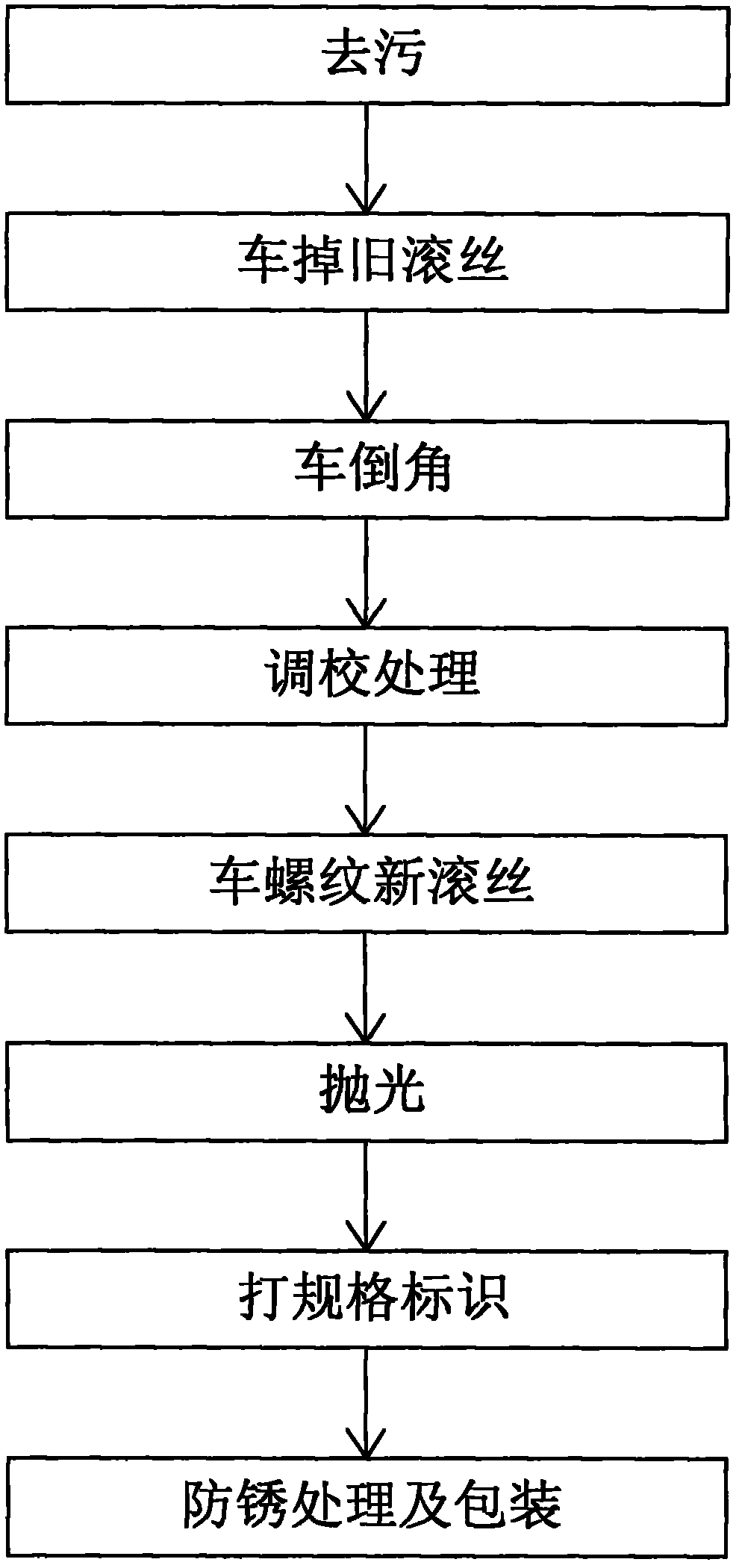

Method for renovating waste thread rolling wheels

A processing method and thread rolling wheel technology, which is applied in the field of refurbishment of waste thread rolling wheels, can solve the problems of large labor loss and high cost, and achieve the effects of increased work efficiency, low cost, and simple refurbishment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of renovation processing method of waste thread rolling wheel, its steps are:

[0023] Decontamination: decontaminate the recovered thread rolling wheel M6×1;

[0024] Turn off the old thread rolling: put the decontaminated thread rolling wheel M6×1 on the ordinary lathe, and remove all the old thread rolling wheels on the outer circle of the thread rolling wheel; place the thread rolling wheel on the ordinary lathe at a speed of 70r / min ,, The axial feed speed along the thread rolling wheel is 0.09mm / r, the radial feed rate along the thread rolling wheel is 1mm, all the old thread rolling is removed; the thread rolling wheel is processed to a diameter of 145.3mm.

[0025] Car chamfering: chamfering the thread rolling wheel with the old thread rolling off the outer circle on the ordinary lathe; the chamfering size of the chamfering treatment on the ordinary lathe is 1×1mm.

[0026] Adjustment processing: put the thread rolling wheel that has been chamfered on th...

Embodiment 2

[0032] A kind of renovation processing method of waste thread rolling wheel, its steps are:

[0033] Decontamination: decontaminate the recovered thread rolling wheel M6×1;

[0034] Turn off the old thread rolling: put the decontaminated thread rolling wheel M6×1 on the ordinary lathe, and remove all the old thread rolling on the outer circle of the thread rolling wheel; place the thread rolling wheel on the ordinary lathe at a speed of 132r / min ,, The axial feed speed along the thread rolling wheel is 0.17mm / r, the radial feed rate along the thread rolling wheel is 2mm, all the old thread rolling is removed, and the thread rolling wheel is processed to a diameter of 145.3mm.

[0035] Car chamfering: chamfering the thread rolling wheel with the old thread rolling off the outer circle on the ordinary lathe; the chamfering size of the chamfering treatment on the ordinary lathe is 1×1mm.

[0036] Adjustment processing: put the thread rolling wheel that has been chamfered on the ...

Embodiment 3

[0042] A kind of renovation processing method of waste thread rolling wheel, its steps are:

[0043] Decontamination: decontaminate the recovered thread rolling wheel M6×1;

[0044] Turn off the old thread rolling: put the decontaminated thread rolling wheel M6×1 on the ordinary lathe, and remove all the old thread rolling on the outer circle of the thread rolling wheel; place the thread rolling wheel on the ordinary lathe at a speed of 105r / min ,, The axial feed speed along the thread rolling wheel is 0.13mm / r, the radial feed rate along the thread rolling wheel is 1.5mm, all the old thread rolling is removed, and the thread rolling wheel is processed to a diameter of 145.3mm.

[0045] Car chamfering: chamfering the thread rolling wheel with the old thread rolling off the outer circle on the ordinary lathe; the chamfering size of the chamfering treatment on the ordinary lathe is 1×1mm.

[0046] Adjustment processing: place the thread rolling wheel that has been chamfered on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com