Combined internal hexagonal spanner device

A hexagonal wrench and wrench technology, applied in the field of combined wrenches, can solve the problems of poor flexibility and strong manual pressure, and achieve the effects of easy carrying and storage, low production cost, and increased holding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

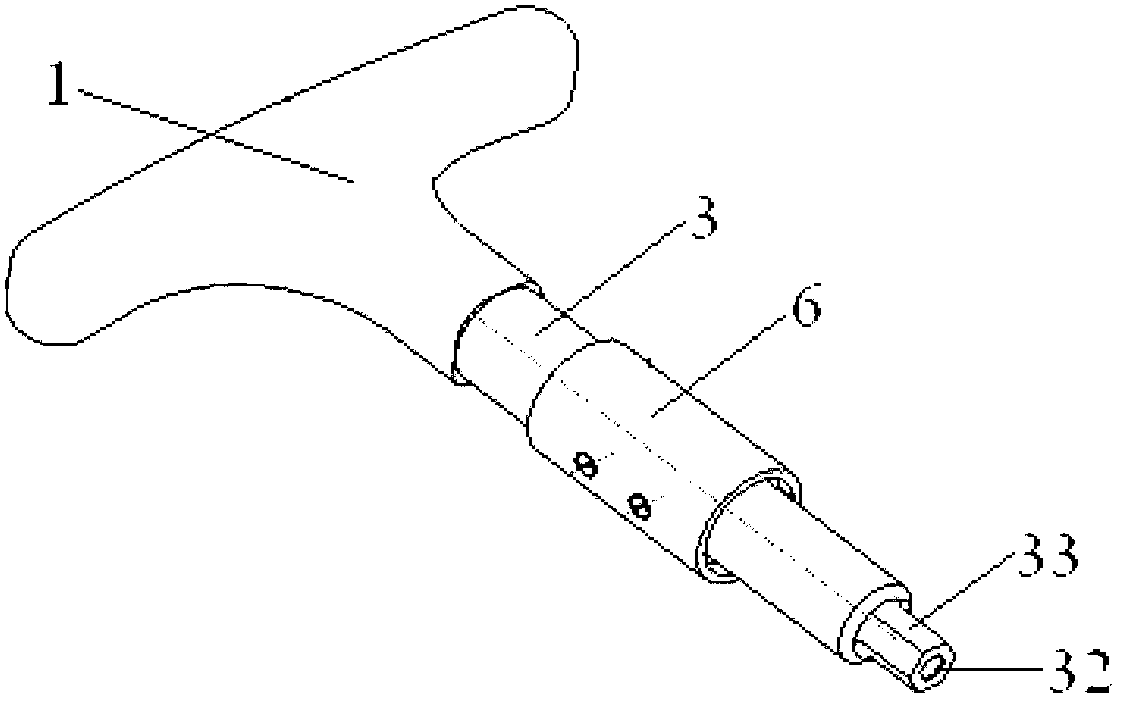

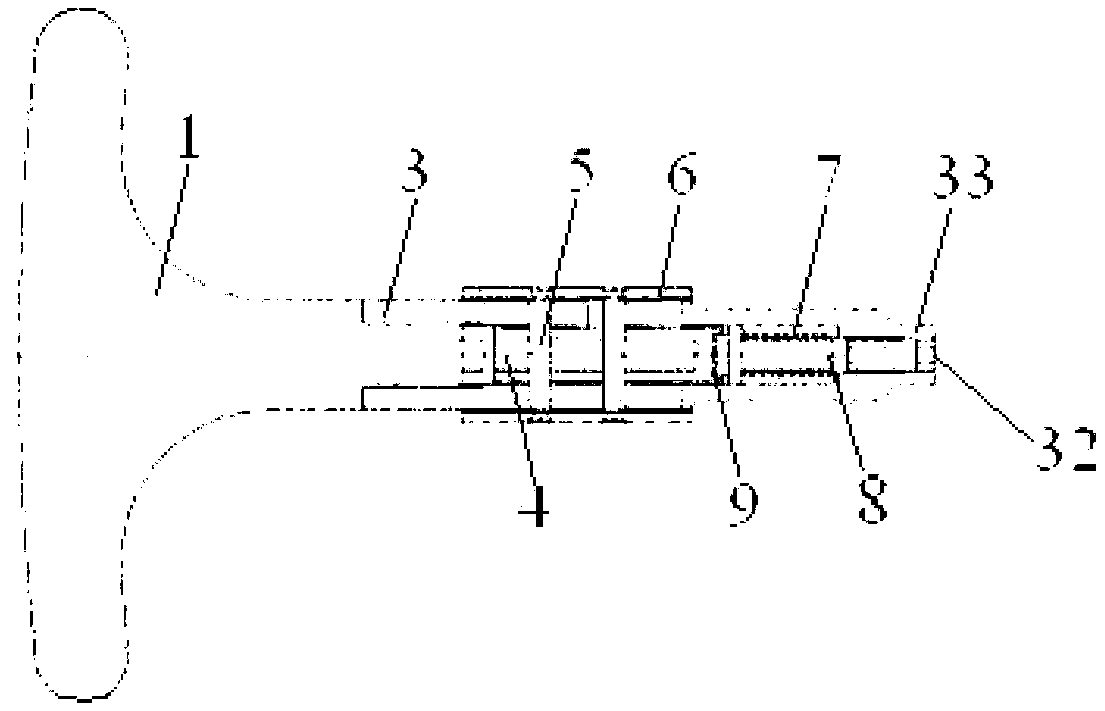

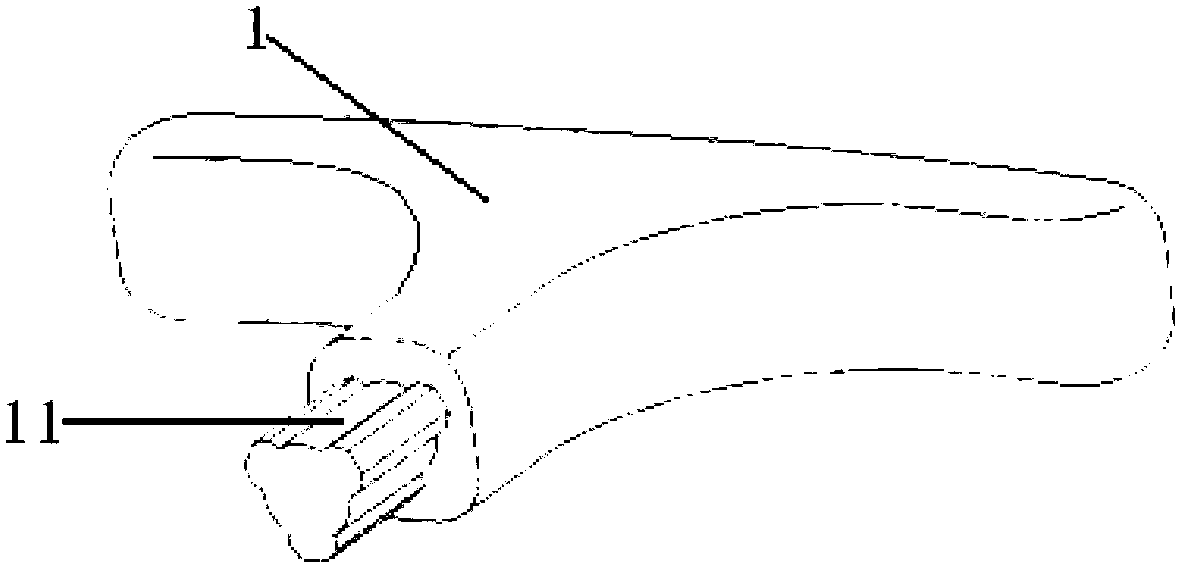

[0030] Specific implementation mode 1. Combination figure 1 Description of this embodiment, the combined hexagonal wrench device includes a handle 1, the shape of the handle 1 is a T-shaped structure, and the connection end is an external flower-shaped interface 11. It is characterized in that it also includes an adapter 2, and the adapter 2 is mainly composed of a sleeve Tube 3, mandrel 4, push rod 5, slip ring 6, compression spring 7 and inner wrench 8, handle 1 and sleeve 3 are connected through a flower-shaped interface, mandrel 4, compression spring 7, and inner wrench 8 are installed on Inside the sleeve 3, the slip ring 6 is installed outside the sleeve 3, the mandrel 4 is connected with the inner wrench 8 through a chute, the push rod 5 is connected with the mandrel 4 through a round hole, and the slip ring 6 is connected with the push rod 5 through a screw. The compression spring 7 is located in the gap between the inner wrench 8 and the sleeve 3 , one end of the comp...

specific Embodiment approach 2

[0048] Embodiment 2. The difference between this embodiment and Embodiment 1 is that this embodiment is a specific working process of Embodiment 1.

[0049] In the free state, the inner wrench 8 does not protrude from the sleeve 3, and the inner wrench 8 can be adjusted to extend or retract the sleeve 3 by changing the position of the slip ring 6 on the sleeve 3. When the inner wrench 8 extends out of the sleeve 3, the inner wrench 8 can be used to fasten or disassemble the corresponding hexagon socket head screw; when the inner wrench 8 is retracted into the sleeve 3, the outer wrench interface on the sleeve 3 can be used 33 to fasten or remove the corresponding hexagon socket head cap screws, and the function of the outer wrench interface 33 is equivalent to that of the outer wrench.

[0050] When using the inner wrench 8, first push and pull the slip ring 6, drive the push rod 5 to slide in the F-shaped chute 34, and drive the mandrel 4 and the inner wrench 8 to slide in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com