Heating device for hydraulic tray welding machine

A heating device and welding machine technology, applied in the field of heating devices, can solve the problems of low heat transfer efficiency, slow temperature rise, uneven temperature distribution, etc., and achieve the effects of good thermal conductivity, stable temperature rise, and high heating and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

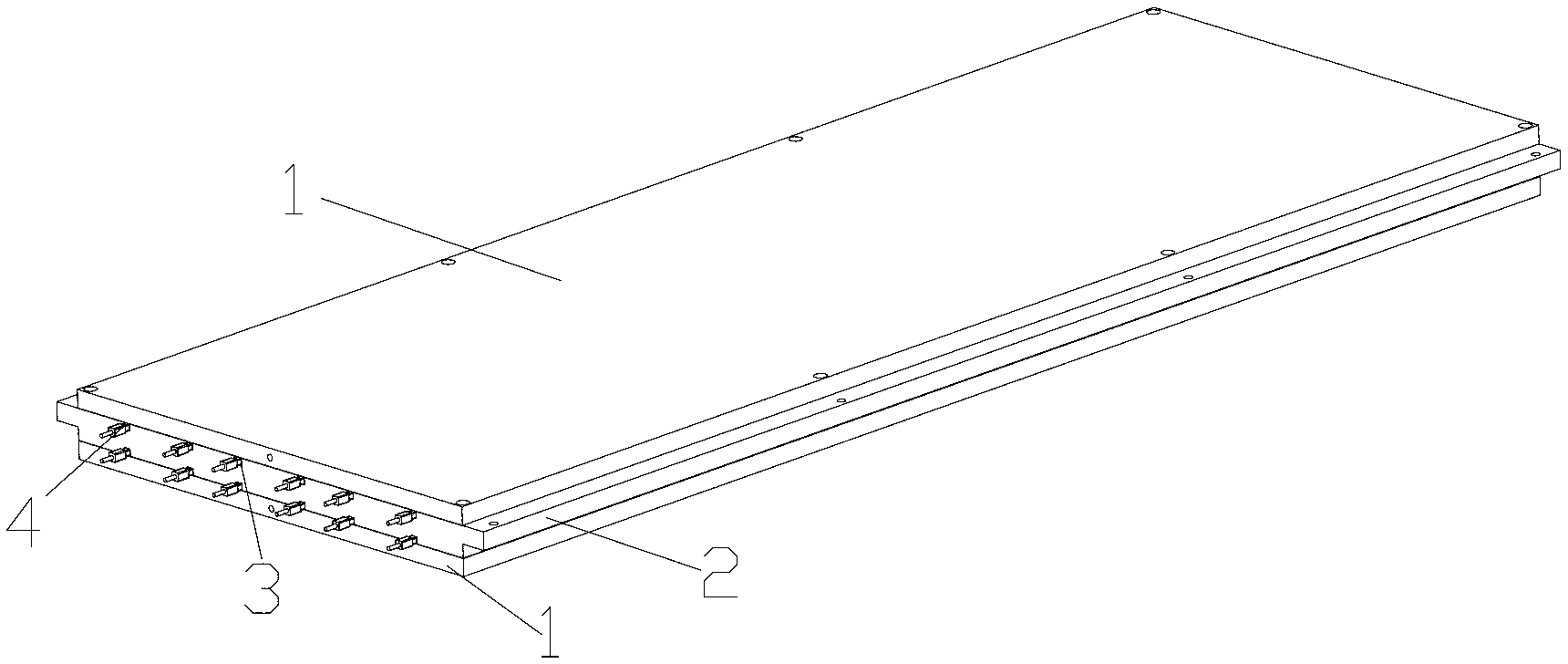

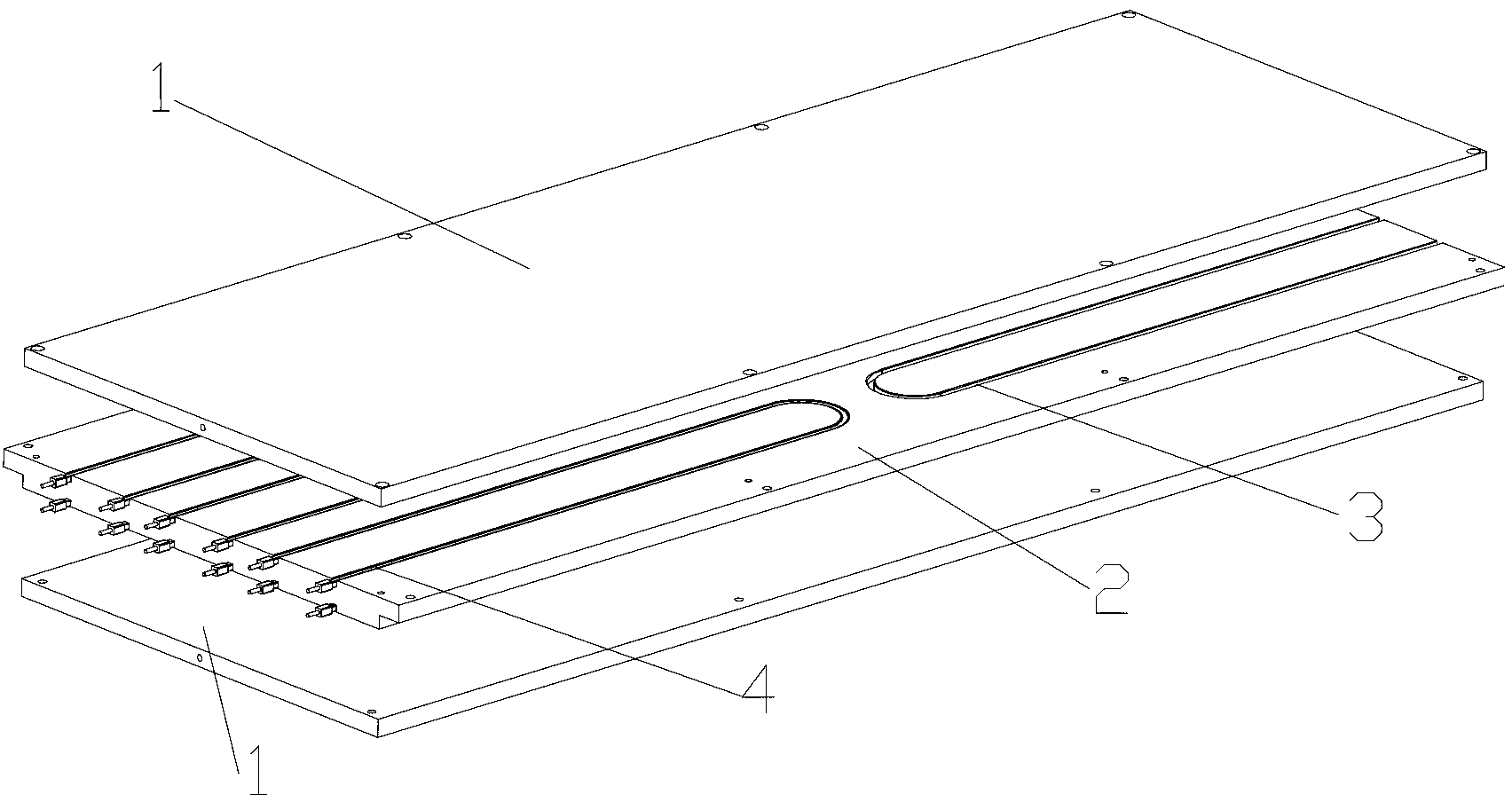

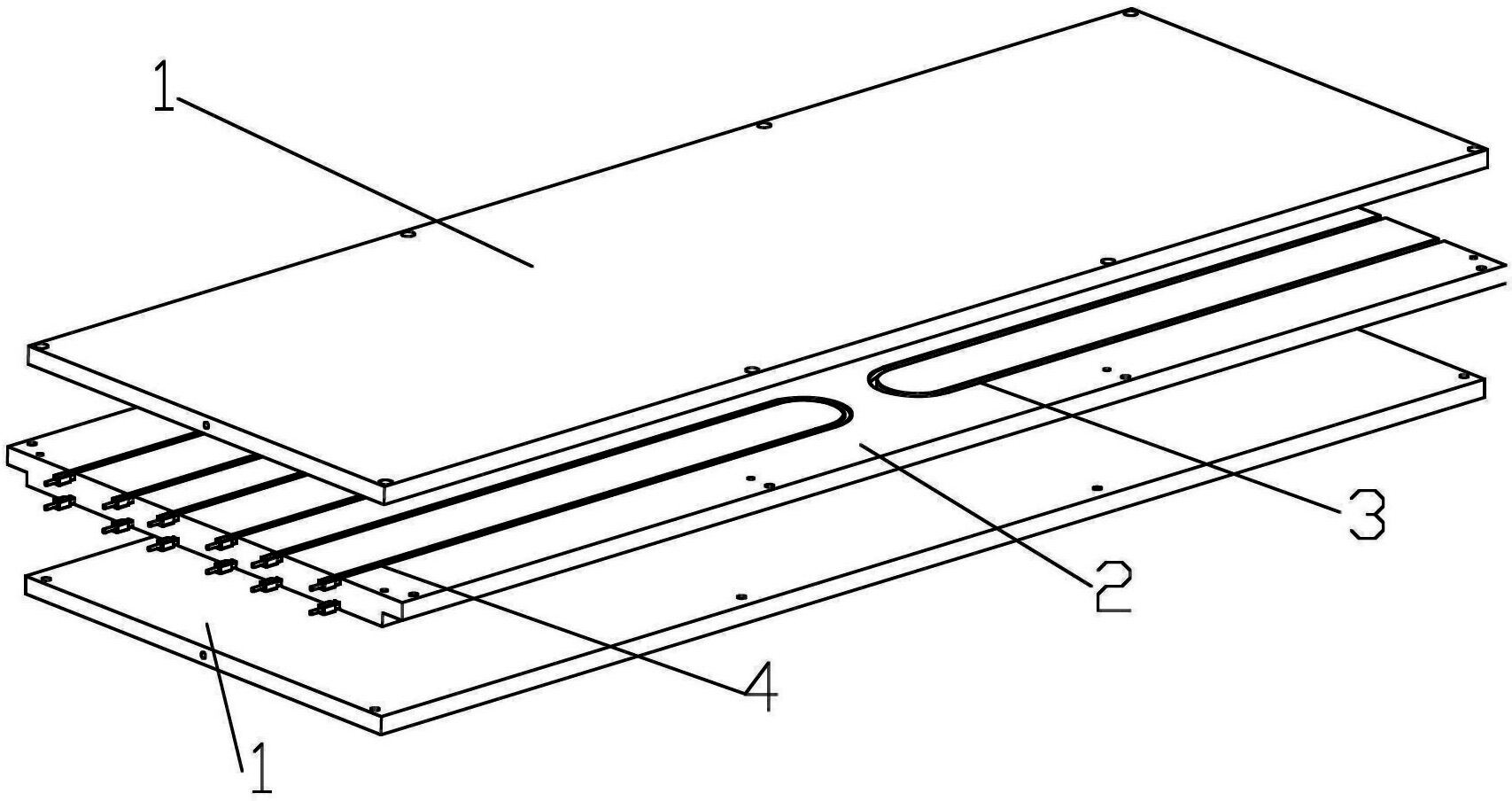

[0012] attached figure 1 , 2 It is a heating device for a hydraulic pallet welding machine according to the present invention, which includes two aluminum plates 1; a steel plate 2 is sandwiched between the two aluminum plates 1; the front and back surfaces of the steel plate 2 are respectively provided with a plurality of U-shaped groove 3; the U-shaped groove 3 is provided with a U-shaped heating strip 4 matching it; the scheme of the present invention arranges a U-shaped groove 3 on the front and back surfaces of the steel plate 2 and places a U-shaped heating strip 4 to increase the heating rate Fast, stable temperature rise, high heat and heat dissipation efficiency. At the same time, U-shaped groove 3 is set on the steel plate 2. When the U-shaped heating strip 4 is damaged, it is easy to replace; the steel plate 2 is sandwiched between two aluminum plates 1, which has good therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com