Jet printing control device and system as well as data processing method

A control device and data technology, applied in the field of data transmission, can solve the problems of longer cycle, reduced printing efficiency, and increased data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An embodiment of the present invention provides a jet printing control device, which can increase data storage capacity and improve jet printing efficiency. Corresponding systems and data processing methods are also provided. Each will be described in detail below.

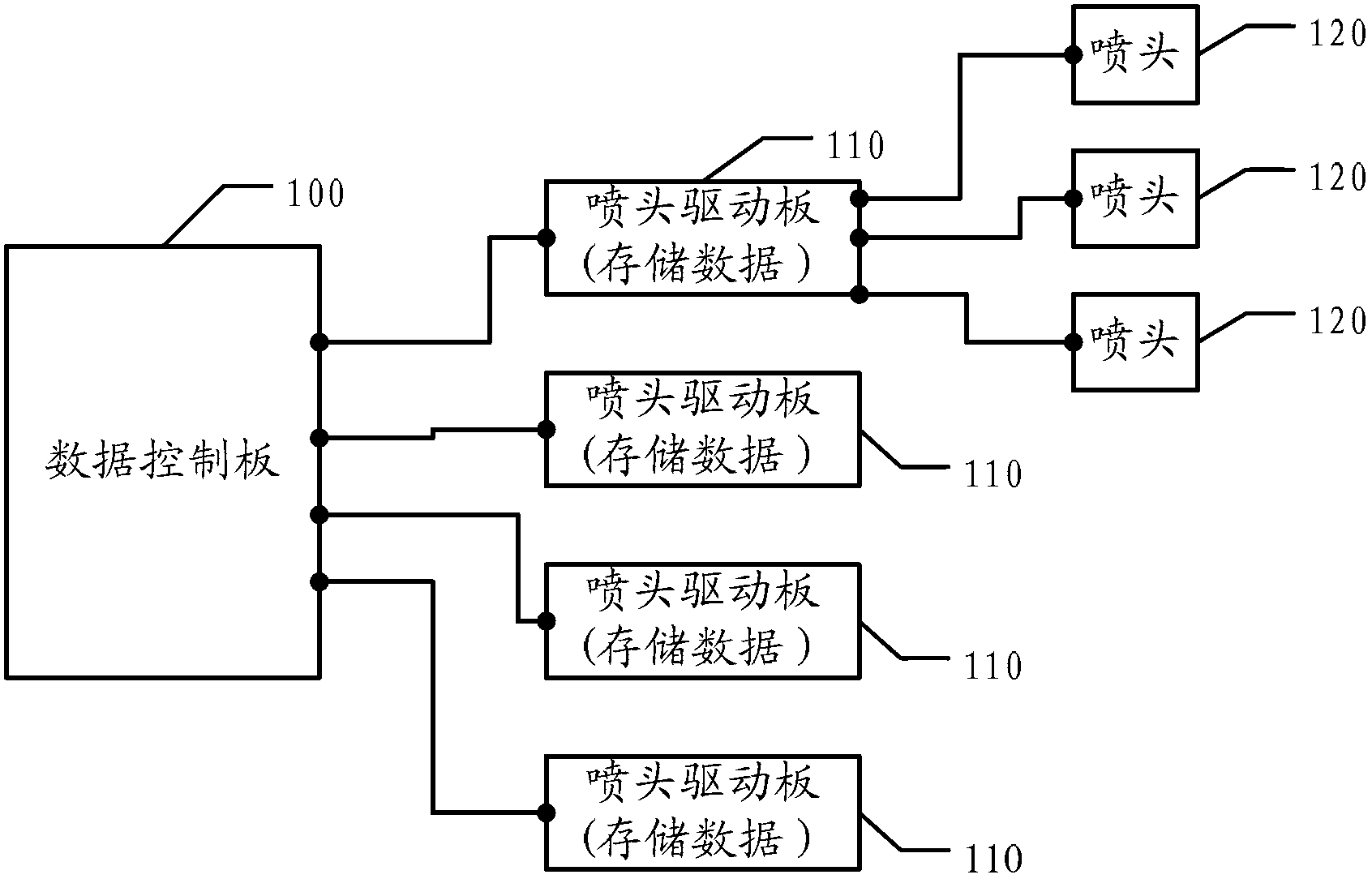

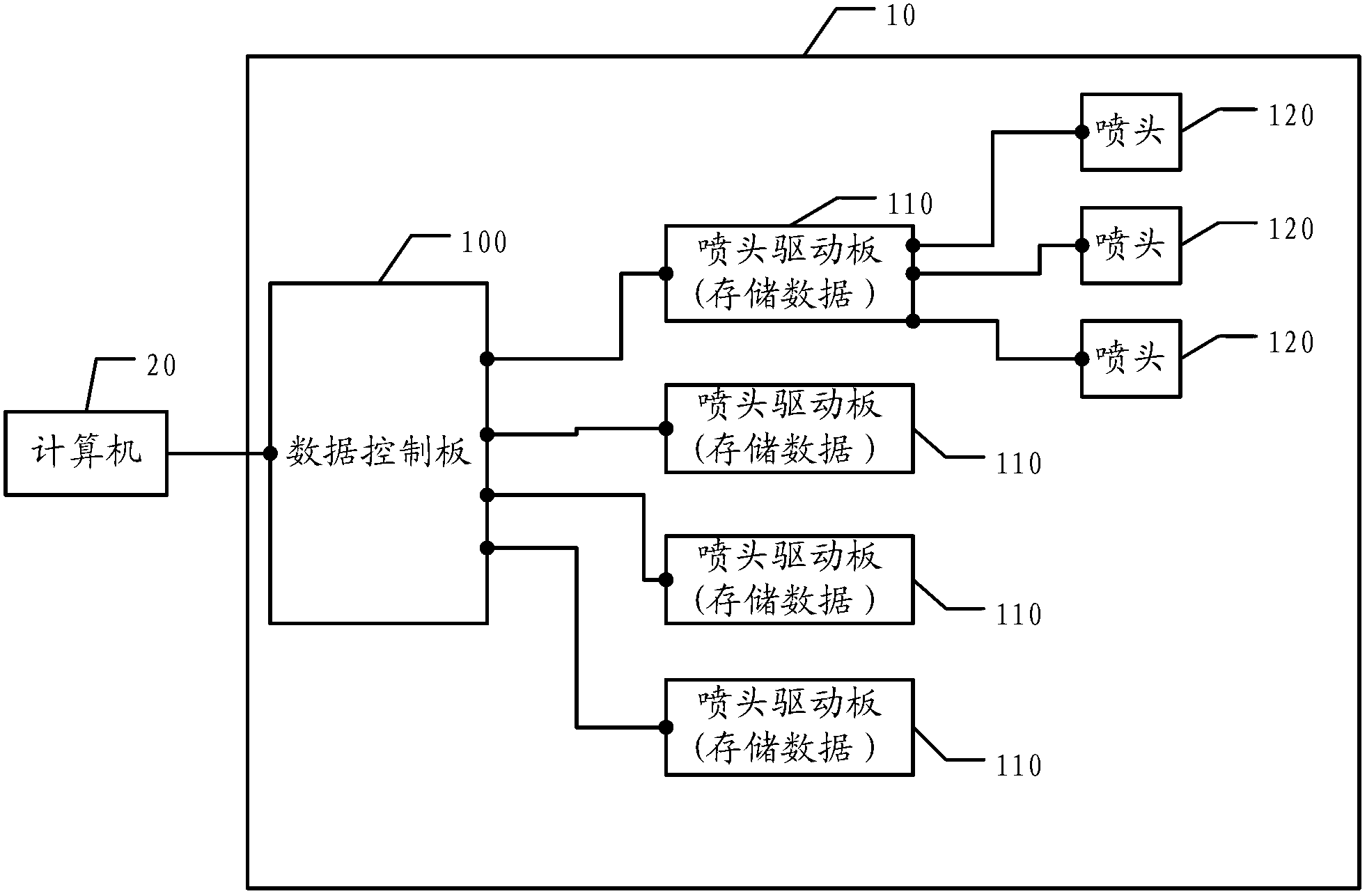

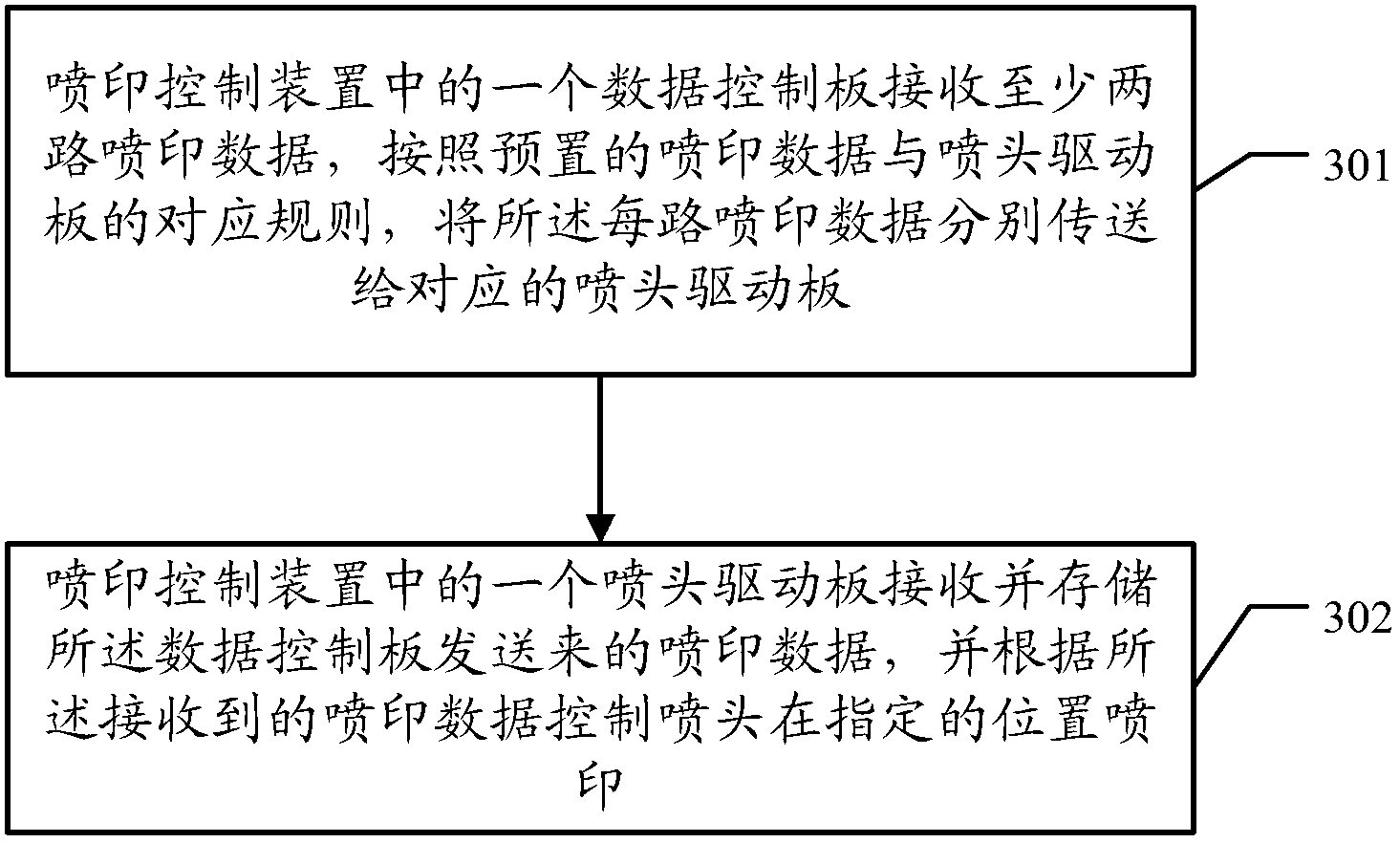

[0027] refer to figure 1 The printing control device provided by the embodiment of the present invention includes: a data control board 100, a nozzle driving board 110 and a nozzle 120, the data control board 100 controls at least two nozzle driving boards 110, and the nozzle driving board 110 controls at least two nozzles 120 ; The data control board 100 is connected to the nozzle driving board 110 through a cable, and the nozzle driving board 110 is connected to the nozzle 120 through a cable. figure 1 The data control board 100 controls 4 print head drive boards 110, and the print head drive board 110 controls 3 print heads as an example to illustrate the spray printing control device provided by the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com