Quantitative packaging scale for sub-package according to amount of grains and quantitative weighing method of quantitative packaging scale

A technology of quantitative packaging and packaging scales, applied in packaging, packaging machines, packaging protection, etc., can solve the problem of large difference in particle number and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

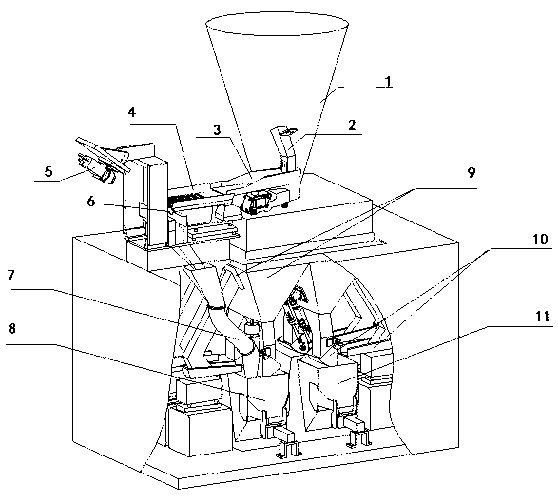

[0032] see figure 1 , the invention discloses a quantitative packaging scale for packing according to grain number. As shown in the figure: it consists of a storage hopper 1, a unit grain weight acquisition unit and a quantitative packaging part. Wherein: the unit grain weight acquisition unit is composed of a sampling device 2, a feeder 3, a multi-row vibrator 4, a storage chute 7, a camera 5, a camera controller, a light source 6, and an input device; the quantitative packaging The part is a single-head quantitative packaging scale or a multi-head quantitative packaging scale, which is composed of a distribution chute 9, a feeding device 10, a weighing hopper 8, 11 and a weighing controller; the unit grain weight acquisition unit and each of the quantitative packaging parts Component actions are coordinated and controlled by PLC;

[0033] The unit grain weight obtaining unit also includes a counting hopper, the effect of the counting hopper is to weigh the material weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com