Material conveying device

A material conveying and support plate technology, which is applied in the directions of transportation and packaging, thin material handling, object supply, etc., can solve the problems of low conveying efficiency and complex structure, and achieve the effect of meeting the conveying demand, high transmission efficiency and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

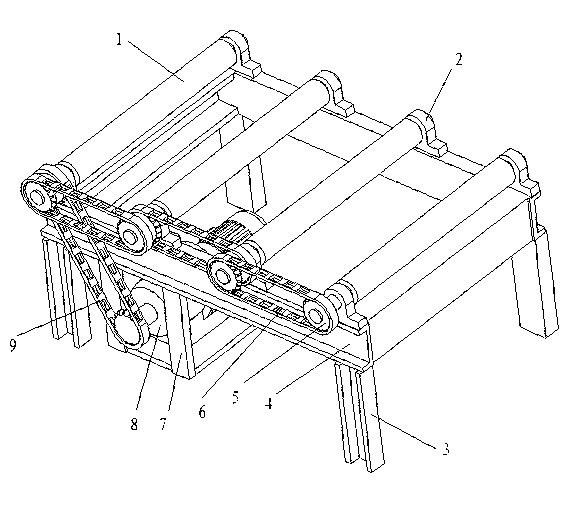

[0013] see figure 1 , The feeding device has a bracket 3, and both sides of the top of the bracket 3 are provided with a U-shaped support plate 4, and several bearing seats 2 are provided on the support plate 4.

[0014] Roller shafts 1 are installed between the bearing housings 2 on the two support plates 4 , transmission gears 5 are arranged on the same side of several roller shafts 1 , and adjacent transmission gears 5 are connected by chains 6 .

[0015] The transmission gear placed at the end of the feeding device is connected with the motor 8 through a chain 9 .

[0016] At the same time, the motor 8 is placed under the roller 1 and installed in the motor fixing frame 7 .

[0017] The above content is only an example and description of the structure of the present invention. Those skilled in the art make various modifications or supplements to the described specific embodiments or replace them in similar ways, as long as they do not deviate from the concept of the inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com