Ink solvent oil and preparation method thereof

A technology of ink solvent oil and heavy oil, which is applied in ink, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of increased ink cost, unsatisfactory fast solvent release performance, and poor low-temperature fluidity, etc., and achieves environmental and human body protection. Harm reduction, solution to unsatisfactory solvency, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-5

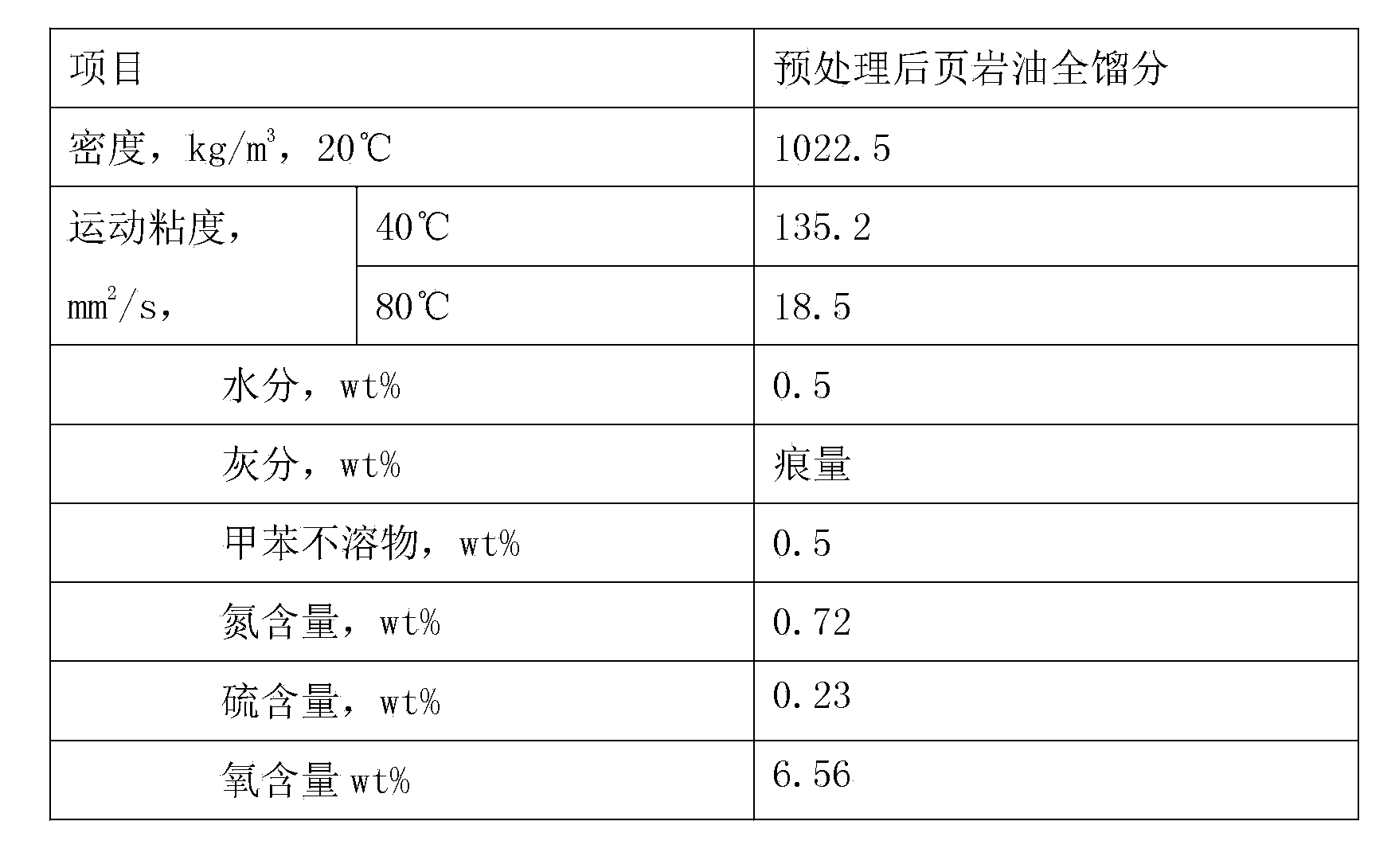

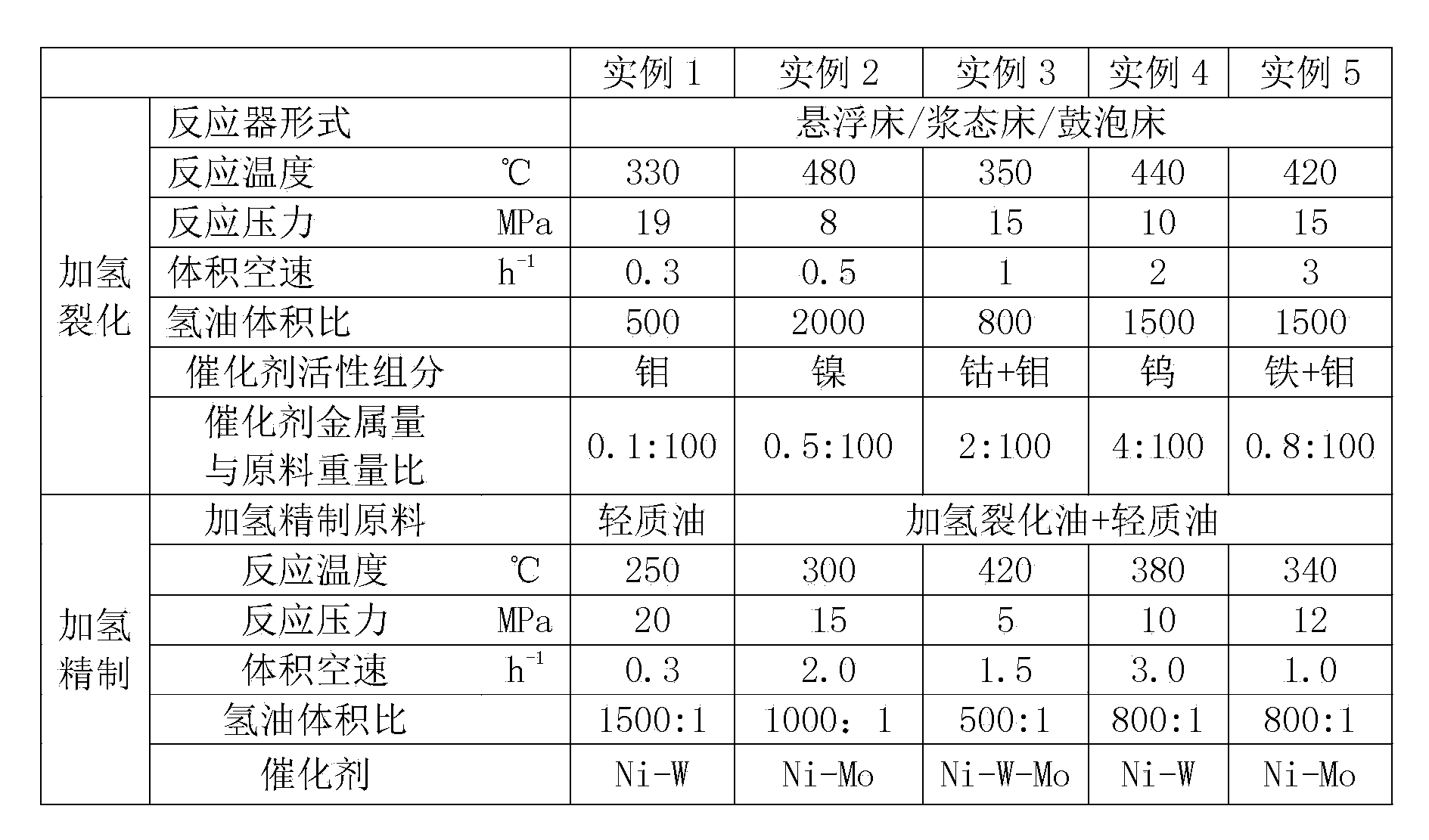

[0025] A typical shale oil is selected as the raw material, and the properties of the shale oil raw material after dehydration to remove mechanical impurities are shown in Table 1. The ink solvent oil was prepared according to the above-mentioned preparation method. The specific process conditions are shown in Table 2. Among them, the processing capacity of the hydrocracking reactor is 0.1t / d, and the processing capacity of the hydrofining reactor is 3L / h.

[0026] Table 1 Properties of shale oil raw materials

[0027]

[0028] Table 2 Hydrocracking and Hydrofining Process Conditions

[0029]

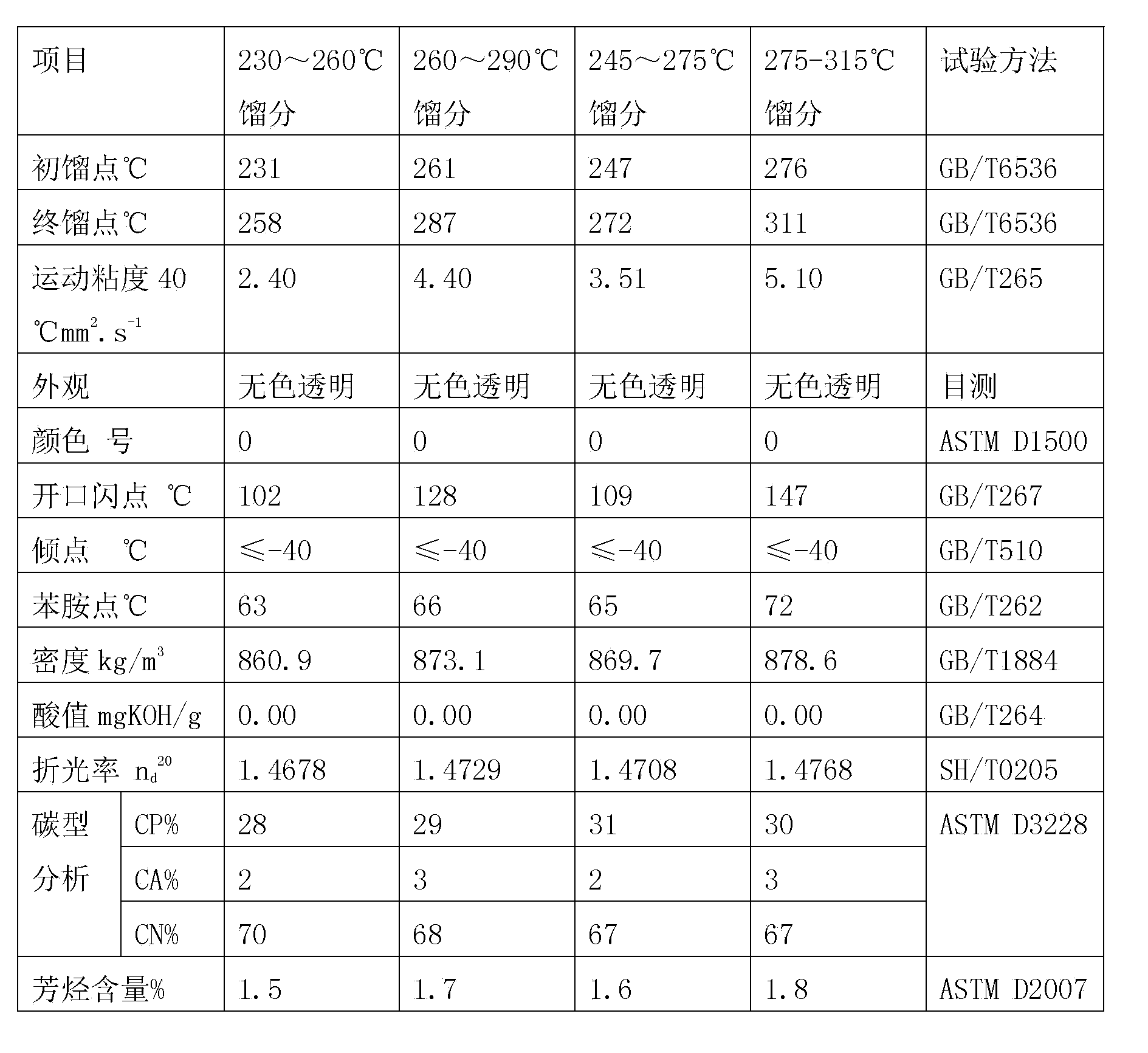

[0030] The hydrotreated shale oil obtained in Example 5 above is subjected to rectification, fractionation and cutting to obtain fractions at 230-260°C, 260-290°C, etc. or fractions at 245-275°C, 275-315°C, etc. to obtain multiple series Ink solvent oil products. The main performance indicators of the product are shown in Table 3 below.

[0031] Table 3 Main performance indicat...

Embodiment 6-10

[0034] A typical coal tar is selected as the raw material, and the properties of the coal tar raw material after dehydration to remove mechanical impurities are shown in Table 4. The ink solvent oil was prepared according to the above-mentioned preparation method, and the specific process conditions are shown in Table 5. Among them, the processing capacity of the hydrocracking reactor is 0.1t / d, and the processing capacity of the hydrofining reactor is 3L / h.

[0035] Table 4 Properties of Coal Tar Raw Materials

[0036]

[0037] Table 5 Hydrocracking and Hydrofining Process Conditions

[0038]

[0039] The coal tar hydrorefined oil obtained in Example 10 above was subjected to rectification, fractionation and cutting to obtain fractions at 230-260°C, 260-290°C, and 295-325°C, etc. to obtain multiple series of ink solvent oil products. The main performance indicators of the product are shown in Table 6 below.

[0040] Table 6 adopts the inventive method to make by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com