Multicolor terylene fat and thin fiber filament produced in variable speed by metering pump and preparation method thereof

A technology for fat and thin fibers and production methods, which is applied in fiber processing, filament/thread forming, feeding solution to spinnerets, etc., can solve the problem of improving wearing comfort, low product differentiation, and poor moisture absorption and air permeability of polyester fabrics. problems, to achieve the effects of good hand feel and air permeability, simple equipment modification, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Manufacture of multi-color polyester fat and thin fiber filaments produced by variable speed metering pumps:

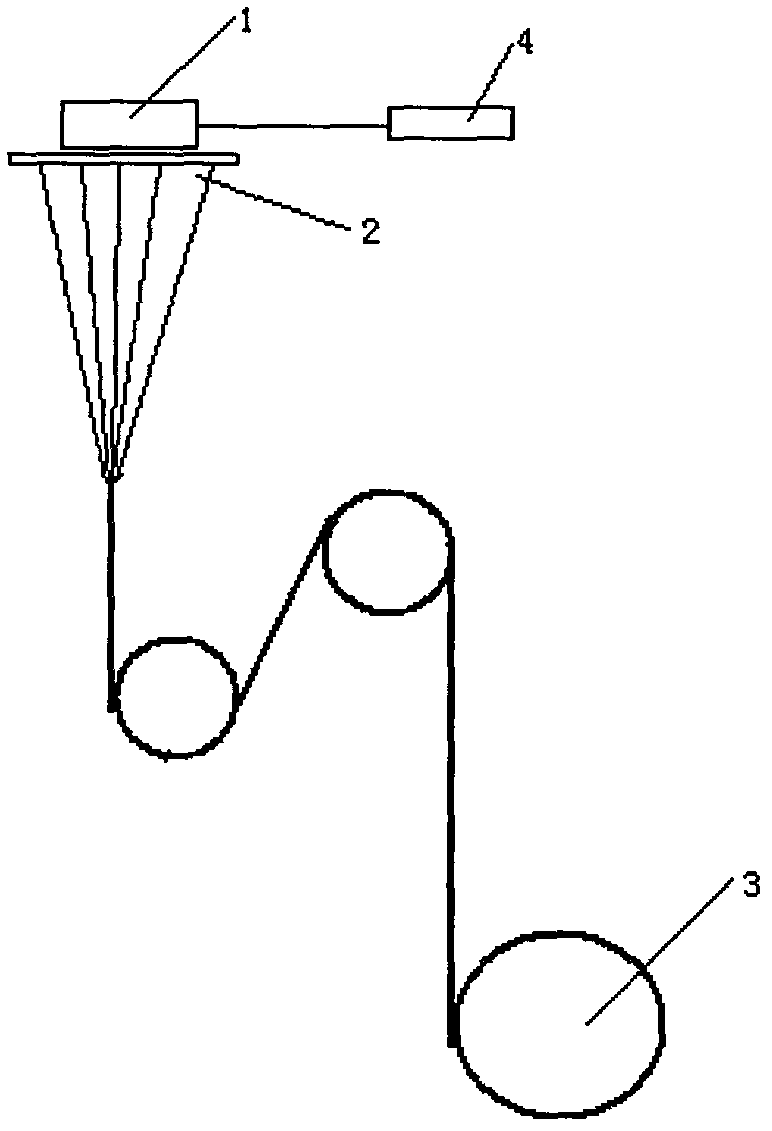

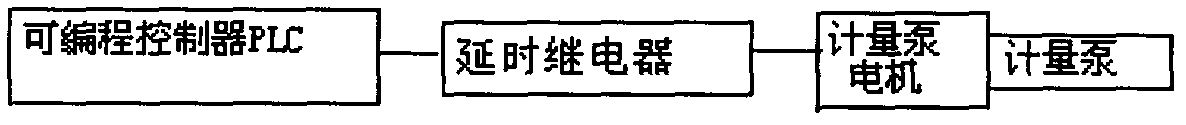

[0030] On the polyester full-drawn yarn FDY device, change the internal control constant-speed working mode of the frequency converter that controls the metering pump (1) motor, and use the multi-stage speed-changing external control mode to work, controlled by the connected programmable controller (4) The metering pump (1) runs at different speeds according to the set program, so that the total stretching ratio of the filament formed by the difference between the extrusion speed of the melt in the spinneret (2) and the speed of the winding head (3) changes accordingly .

[0031] One hot roller V=1300m / min, second hot roller speed V1=3500m / min Metering pump frequency multi-stage speed: h1=20hz, h2=21hz, h3=23hz, corresponding time: t1=1ms, t2=1ms, t3=1ms ,, the acceleration time is 0.01 seconds.

[0032] The obtained thick and thin fiber section length is 15c...

Embodiment 2

[0034] Manufacture of polyester multi-color slub full-drawn yarn FDY produced by metering pump variable speed:

[0035] On the polyester full-drawn yarn FDY device, change the internal control constant-speed working mode of the frequency converter that controls the metering pump (1) motor, and use the multi-stage speed-changing external control mode to work, controlled by the connected programmable controller (4) The metering pump (1) runs at different speeds according to the set program, so that the total stretching ratio of the filament formed by the difference between the extrusion speed of the melt in the spinneret (2) and the speed of the winding head (3) changes accordingly .

[0036] One hot roller V=1500m / min, second hot roller speed V1=4300m / min Metering pump frequency multi-stage speed: h1=50hz, h2=50hz, h3=54hz, corresponding time: t1=1ms, t2=3ms, t3=5ms ,, the acceleration time is 0.05 seconds.

[0037] The thick and thin fiber segment lengths are 60cm, 75cm, the...

Embodiment 3

[0039] Manufacture of polyester multi-color slub full-drawn yarn FDY produced by metering pump variable speed:

[0040] On the polyester full-drawn yarn FDY device, change the internal control constant-speed working mode of the frequency converter that controls the metering pump (1) motor, and use the multi-stage speed-changing external control mode to work, controlled by the connected programmable controller (4) Make the metering pump (1) run at different speeds according to the set program, so that the total stretching ratio of the filament formed by the difference between the extrusion speed of the melt in the spinneret hole (2) and the speed difference of the winding head (3) Variety.

[0041] One hot roller V=1300m / min, second hot roller speed V1=3900m / min metering pump frequency multi-stage speed: h1=80hz, h2=84hz, h3=88hz, h4=92hz, corresponding time: t1=2ms, t2=4ms , t3=5ms, t4=4s, the acceleration time is 0.03 seconds.

[0042] 450D / 144F four-color polyester fat and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com