Flax mulberry fiber blend dyeing knitting yarn and manufacture method

A technology of mulberry fiber and flax fiber, applied in the field of knitting yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

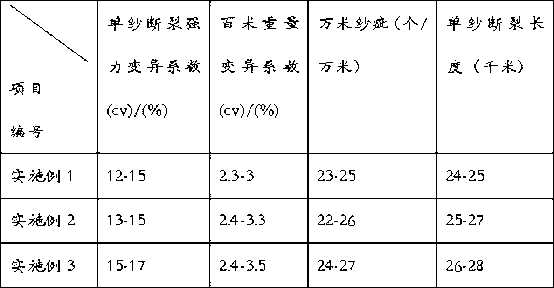

Examples

Embodiment 1

[0028] (b) Roving semi-degumming: pickling, adding 2.8g / l compound acid and 2g / l penetrating agent, pickling temperature: 28°C, pickling time: 30 minutes;

[0029] (c), adding 1.5g / l of chlorinated chlorine for bleaching, the bleaching temperature is: 45°C, and the bleaching time is: 40 minutes;

[0030] Add 1g / L sodium sulfite for dechlorination, dechlorination temperature: 45°C, dechlorination time: 10 minutes;

[0031] Add hot water at 50°C for rinsing, the rinsing time is: 10 minutes;

[0032] (d), biological enzyme pretreatment before dyeing: add compound biological degumming enzyme 3.5 g / l and incubate at 50°C for 30 minutes, drain the liquid after treatment;

[0033] (e), dyeing: add dye with a weight ratio of 4% to the dyed yarn to be dyed; heat up to 60°C; cycle for 15 minutes; add salt: 20 g / l, sodium sulfate: 15 g / l; cycle for 15 minutes Minutes; add salt: 22g / l, sodium sulfate 15 g / l; cycle for 15 minutes; add salt: 20 g / l, sodium sulfate: 15 g / l; cycle for 25 mi...

Embodiment 2

[0038] (b) Roving semi-degumming: pickling, adding 3g / l compound acid and 2g / l penetrating agent, pickling temperature: 32°C, pickling time: 30 minutes;

[0039] (c), adding 0.7g / l of chlorinated chlorine to carry out bleaching, the bleaching temperature is: 45 ℃, and the bleaching time is: 42 minutes;

[0040] Add 1.5g / L sodium sulfite for dechlorination, dechlorination temperature: 47°C, dechlorination time: 12 minutes;

[0041] Add hot water at 55°C for rinsing, the rinsing time is: 10 minutes;

[0042] (d) Biological enzyme pretreatment before dyeing: add compound biological degumming enzyme 4 g / l, incubate at 55°C for 35 minutes, drain after treatment;

[0043] (e), dyeing: add dyes with a weight ratio of 5% of the dyed yarn to be dyed; heat up to 60°C; cycle for 17 minutes; add salt: 25 g / l, sodium sulfate: 15 g / l; cycle 12 Minutes; add salt: 20 g / l, sodium sulfate 15 g / l; cycle for 10 minutes; add salt: 20 g / l, sodium sulfate: 17 g / l; cycle for 20 minutes; add soda as...

Embodiment 3

[0048] (b) Roving semi-degumming: pickling, adding 3.5g / l compound acid and 2.5g / l penetrating agent, pickling temperature: 32°C, pickling time: 35 minutes;

[0049] (c), adding 2g / l of chlorinated chlorine to carry out bleaching, the bleaching temperature is: 50 ℃, and the bleaching time is: 45 minutes;

[0050] Add 1g / L sodium sulfite for dechlorination, dechlorination temperature: 45°C, dechlorination time: 10 minutes;

[0051] Add hot water at 55°C for rinsing, the rinsing time is: 10 minutes;

[0052] (d) Biological enzyme pretreatment before dyeing: add compound biological degumming enzyme 4.5 g / l, incubate at 60°C for 40 minutes, drain after treatment;

[0053] (e), dyeing: add dye with a weight ratio of 6% to the dyed yarn to be dyed; heat up to 60°C; cycle for 20 minutes; add salt: 25 g / l, sodium sulfate: 20 g / l; cycle 10 Minutes; add salt: 20 g / l, sodium sulfate 15 g / l; cycle for 15 minutes; add salt: 25 g / l, sodium sulfate: 20 g / l; cycle for 20 minutes; add soda ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com