Loader auxiliary parking device using load as power source

A technology for loaders and power sources, which is applied to earth movers/shovels, construction, etc., can solve problems such as inability to provide safe and stable parking brakes, and achieve good market promotion prospects, easy implementation, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

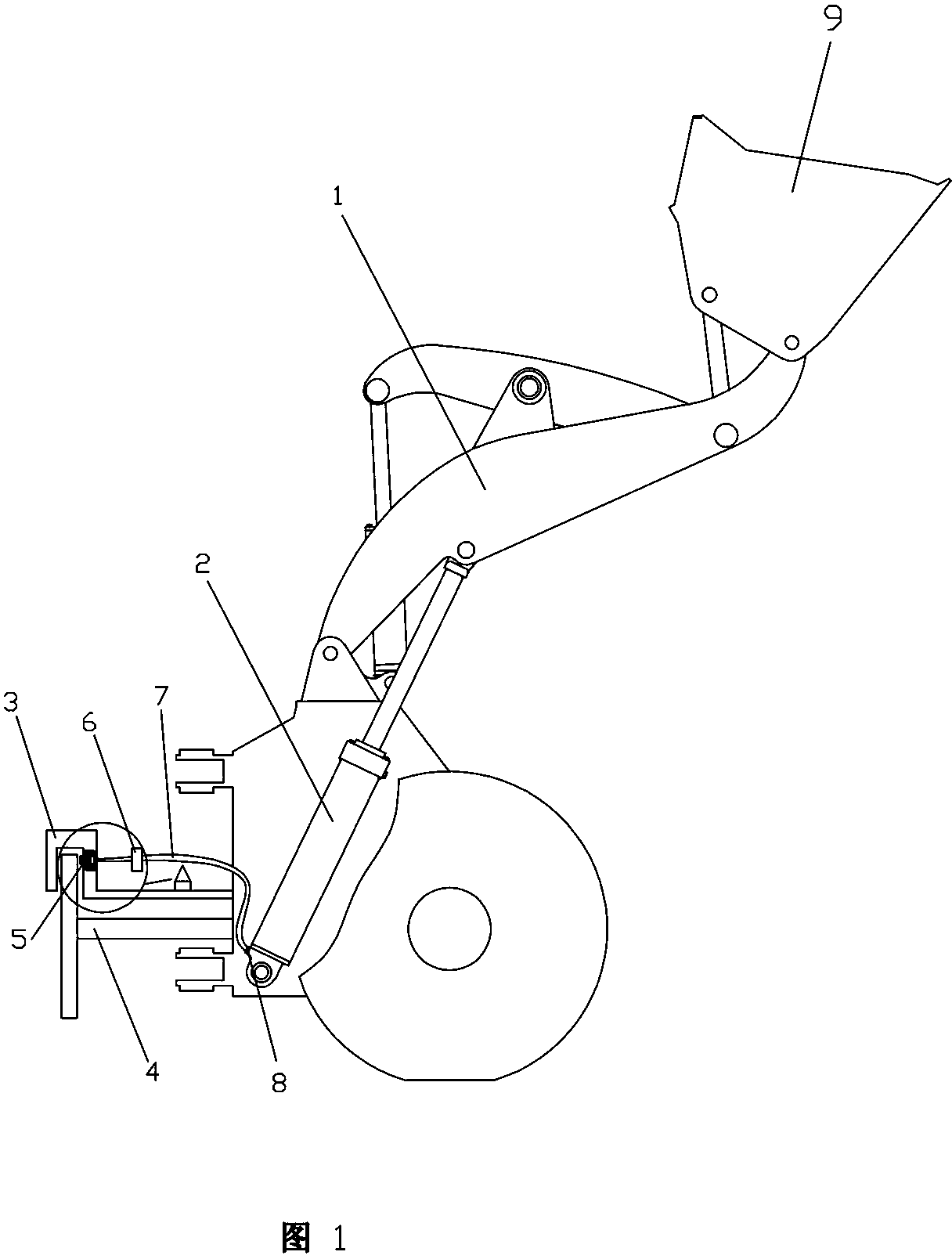

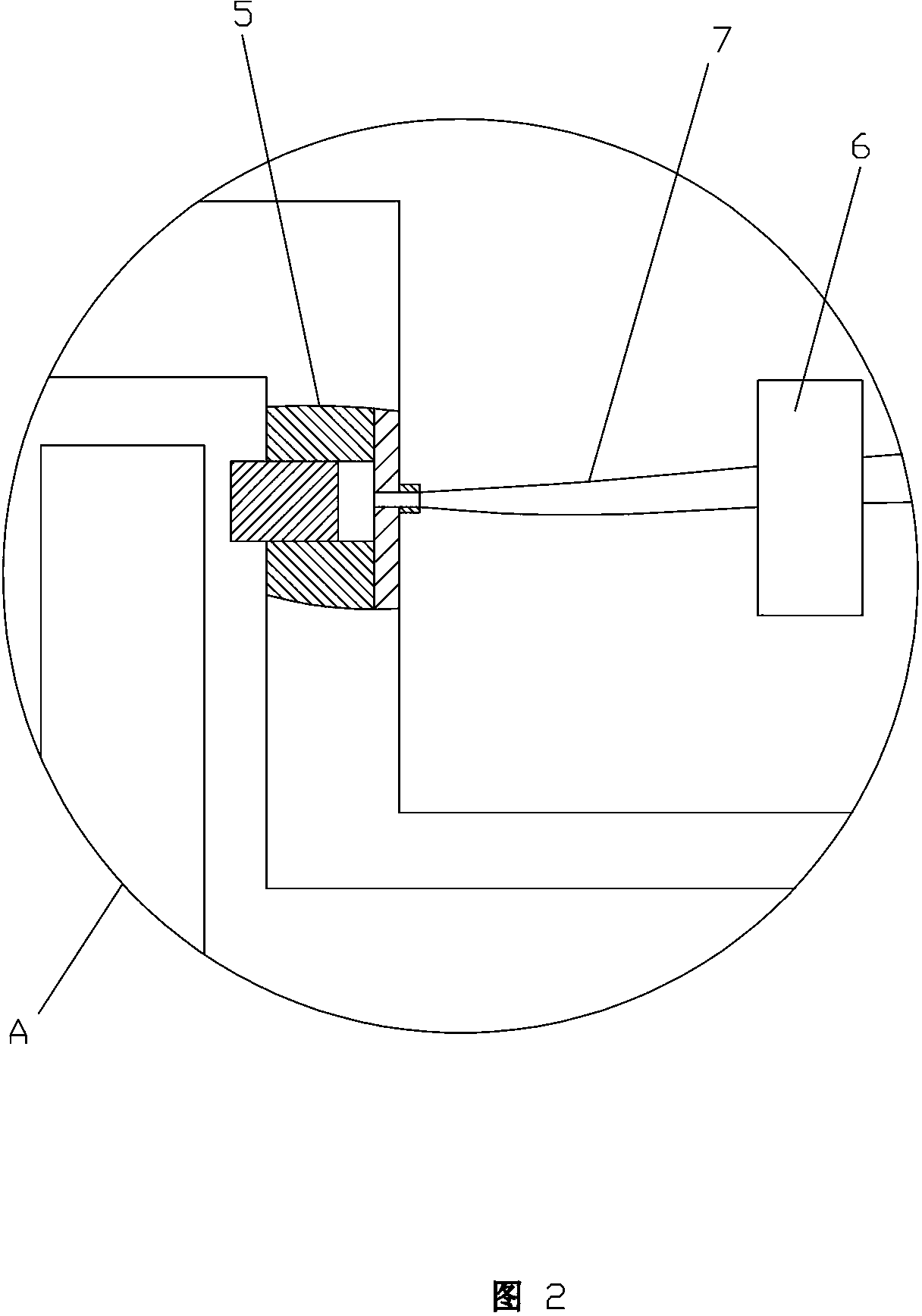

[0012] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0013] Also refer to figure 1 and figure 2 , a loader auxiliary parking device with a load as the power source, comprising a frame working machine body 1, a hydraulic cylinder 2, a parking brake 3 and a transmission shaft 4, and the parking brake 3 is equipped with a brake caliper The piston 5 and the brake caliper brake piston 5 are connected through an oil pipe 7 equipped with a solenoid valve 6 , and the other end of the oil pipe 7 is connected to the oil port 8 at the bottom of the hydraulic cylinder 2 . The hydraulic cylinder 2 and the brake caliper brake piston 5 are connected to each other through the oil pipe 7. When the loading hopper 9 carries heavy materials, it will generate a downward pressure on the hydraulic cylinder 2. The hydraulic oil in the hydraulic cylinder 2 must have Enough pressure can support the loading hopper 9. When braking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com