Device and method for detecting drilling fluid return flow

A flow detection device and flow detection technology, which are used in earth-moving drilling, flushing wellbore, wellbore/well components, etc., can solve the problems of large error, low precision, and delay in reflection, and achieve small cross-sectional width and real-time performance. The effect of good sex and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

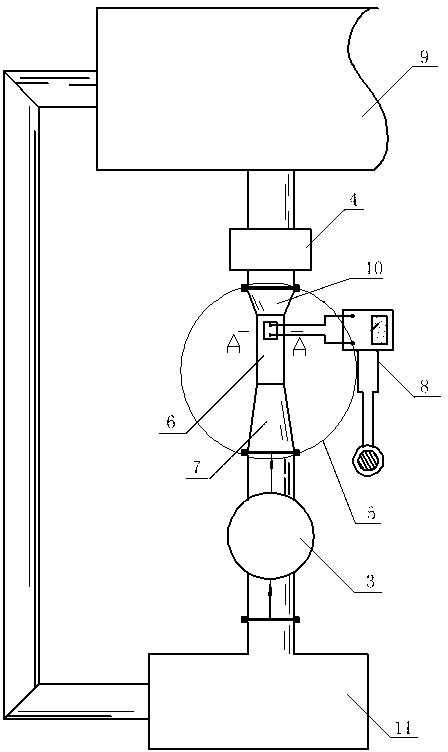

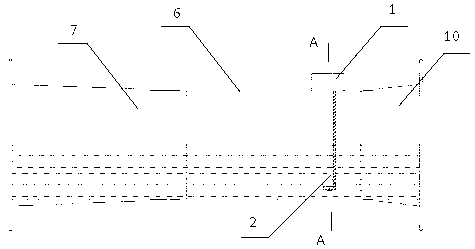

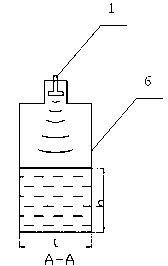

[0023] Such as figure 1 , figure 2 , image 3 As shown, a drilling fluid return flow detection device is composed of one or more flow measurement nipples 5 installed between the wellbore drilling fluid return outlet 3 and the vibrating screen 4, and the flow measurement nipples 5 include Rectangular section flow section 6 and bell mouth buffer sections located at both ends of rectangular section flow section 6, liquid level sensor 1 is installed on the top of rectangular section flow section 6, flow velocity sensor 2 is installed in the internal liquid flow of rectangular section flow section 6 , the liquid level sensor 1 and the flow rate sensor 2 are electrically connected to the calculation and display alarm unit 8 respectively.

[0024] A drilling fluid return flow de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com