Electromagnetic differential safety valve

A safety valve and electromagnetic technology, applied in the field of safety valves, can solve the problems of large opening resistance, high spring stiffness and compression requirements, unreliable closing, etc., and achieve the effect of reducing rigidity requirements, avoiding valve frequency jumps, and reliable closing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

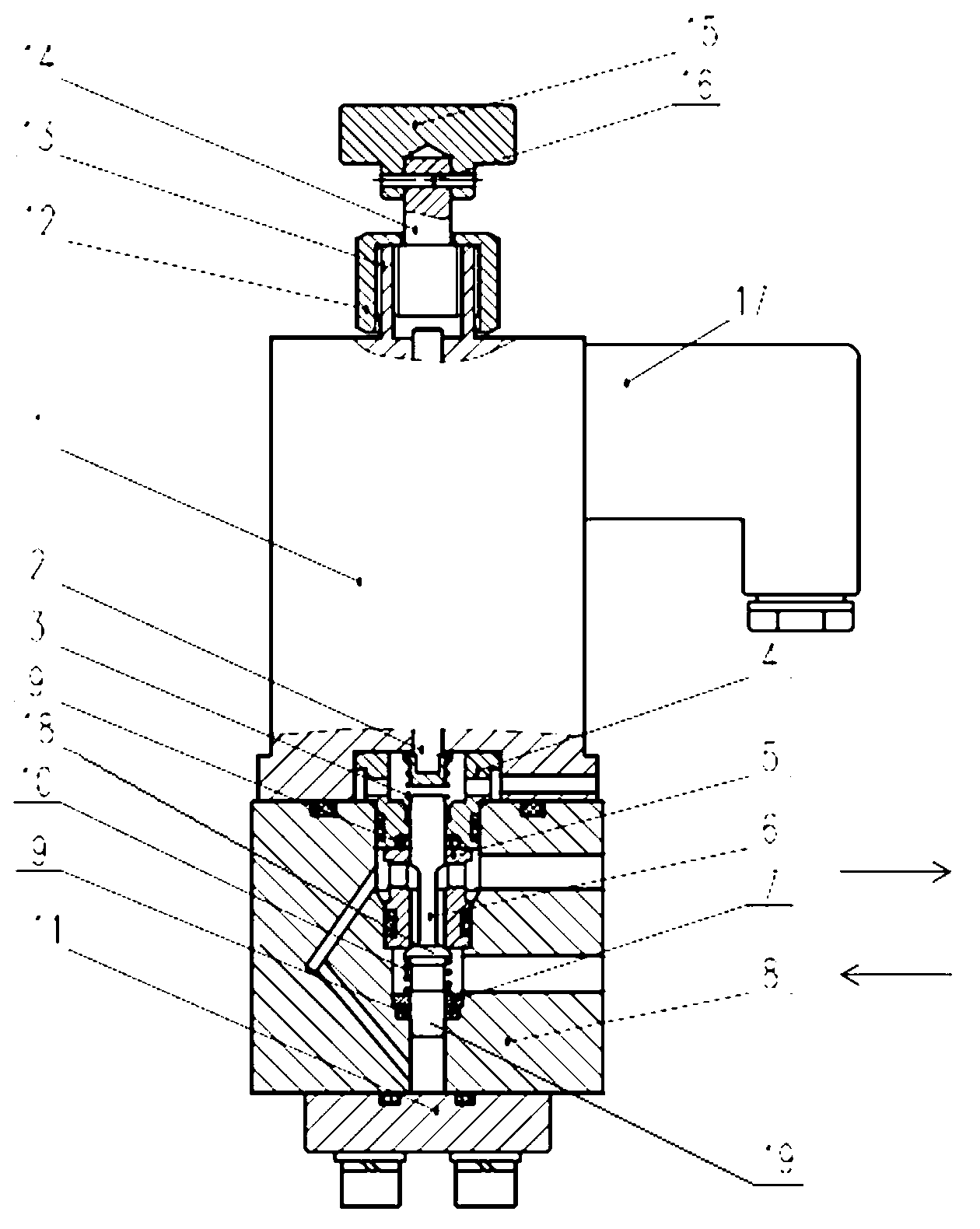

[0013] An example of this electromagnetic differential safety valve is figure 1 As shown, the safety valve is an integrated electromagnetic differential safety valve, which mainly includes a safety valve body, an electromagnetic drive part and an oil drain valve drive part.

[0014] Main part: including valve disc 18, valve seat 4, high pressure interface and low pressure interface. The valve disc 18 adopts a cone valve structure, and a valve core 6 extends along the closing direction of the valve disc 18. The valve core 6 slides and seals through the valve seat 4 and the valve sleeve 5, and the high-pressure port is set on the valve disc. 18 on one side of the opening direction, the low-pressure port is set on the side of the valve disc 18 in the closing direction; the valve seat 4 is provided with a flow port corresponding to the low-pressure port position, and the valve core 6 is provided with a communication port and the valve disc 18; the valve disc 18 is extended along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com