Lower installation base of installation base and covering plate of installation base

A technology of mounting seat and lower seat, which is applied in the field of architectural decoration, can solve the problems of undisclosed electric heating wire connection, increase manufacturing cost, troublesome production, etc., and achieve the convenience of mass industrial production, improve safety and reliability, and simple installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] (Example 1, the mounting base of the mounting base)

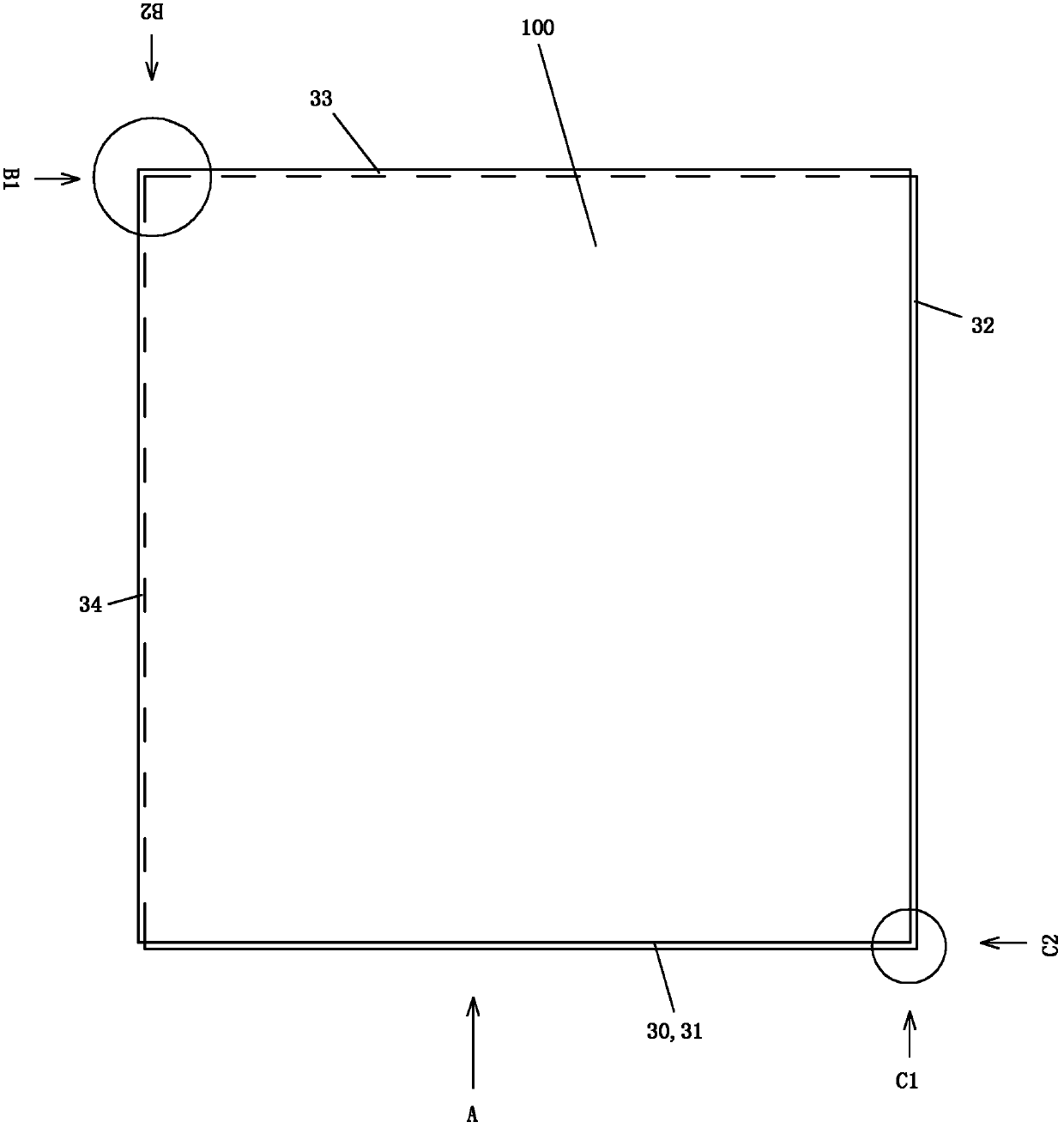

[0095] See Figure 14 , The lower mounting seat 71 of the mounting base is a left-right symmetrical injection molded integral piece.

[0096] See Figure 12 , the lower seat 71 is installed by the connecting part 71-1, the step flange part 71-2, the lower half socket part 71-3, the first positioning plate 71-4, the second positioning plate 71-5 and the snap hook part 71- 6 composition. The connection part 71-1, the lower half socket part 71-3 and the locking hook part 71-6 of the lower seat 71 are connected sequentially from back to front.

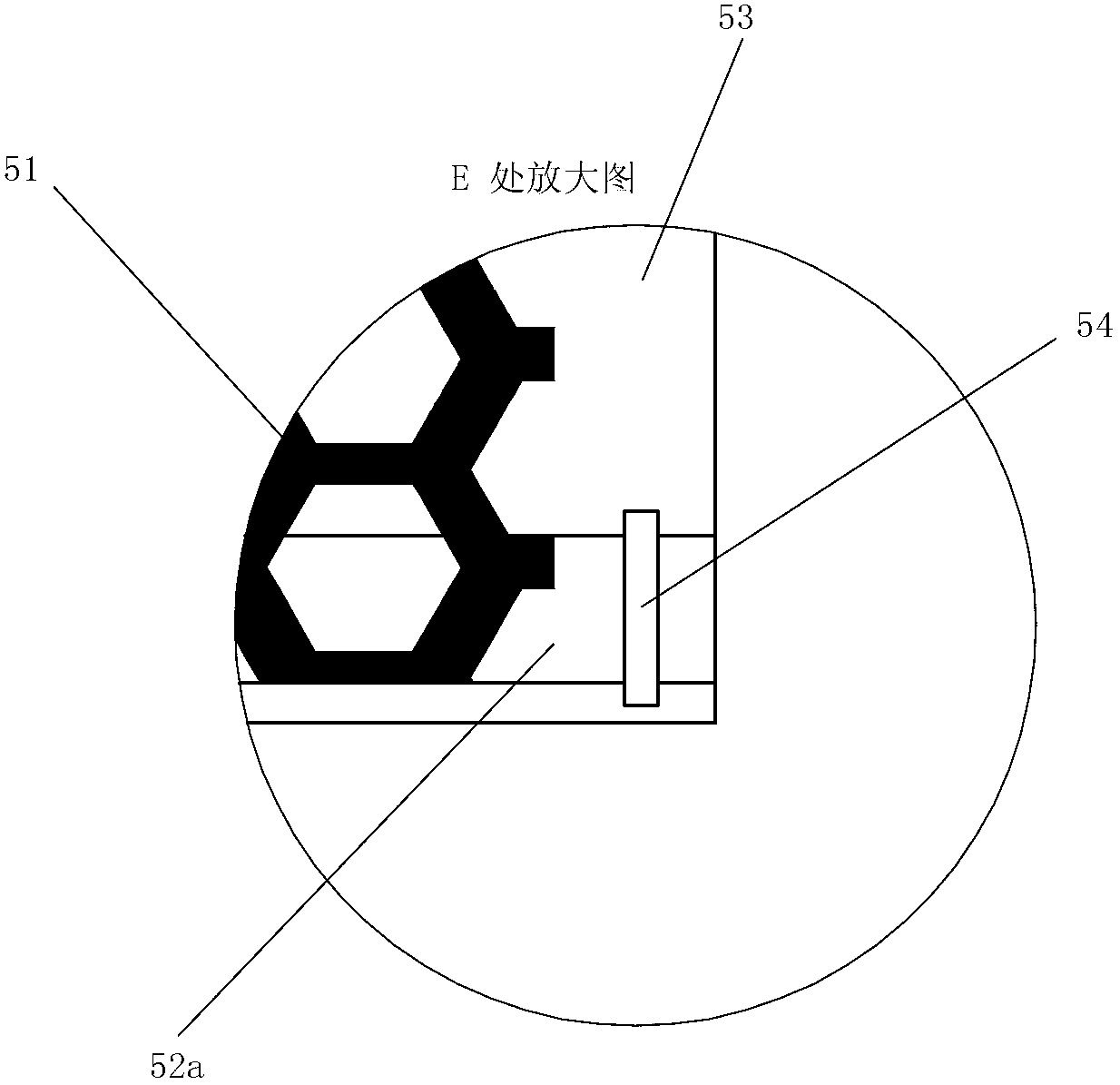

[0097] There are two snap-in hooks in the snap-in hook part 71-6, which are divided into the first snap-in hook 71-6-1 on the left side and the second snap-in hook on the right side according to the difference in left and right positions. 71-6-2; the first locking hook 71-6-1 is located on the left side of the front side of the lower half socket part 71-3, and the second lock...

Embodiment 2

[0110] (Example 2, the cover plate of the mounting seat)

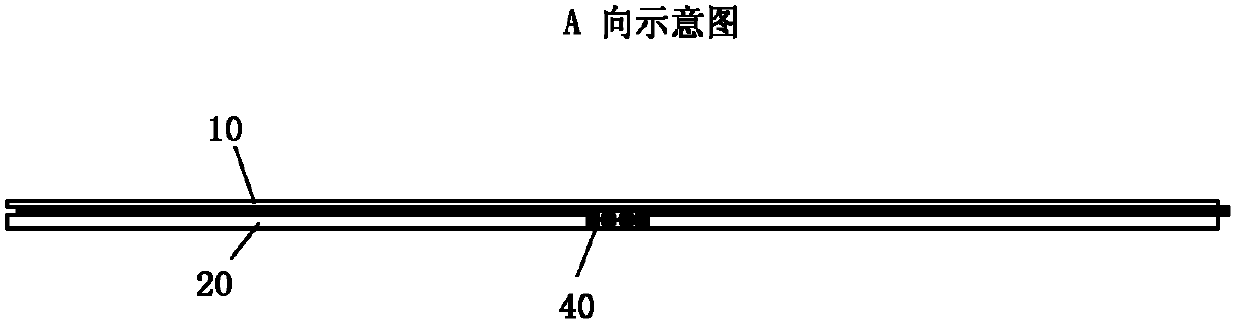

[0111] See Figure 15 , The cover plate 72 is composed of an upper half socket portion 72-1 located at its front portion and a pressing plate portion 72-2 located at its rear portion. The upper side of the pressing plate part 72-2 is located in the same plane as the upper side of the upper half of the socket part 72-1, and the lower side of the pressing plate part 72-2 is higher than the lower end surface of the upper half of the socket part 72-1.

[0112] The upper half socket portion 72-1 of the cover plate 72 is provided with a first plug slot 72-1-1, a second plug slot 72-1-2, a first pin slot 72-1-3, a second pin slot 72 -1-4, upper lateral groove 72-1-5 and insertion hole 72-1-6.

[0113] The upper lateral groove 72-1-5 is located at the rear lower middle of the upper half socket part 72-1, and the upper lateral groove 72-1-5 opens backward and is arranged along the left and right directions. The upper side tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com