Radial gradually-wide type fin-structure grooved panel heat pipe and processing method thereof

A flat heat pipe and radial technology, which is applied in the field of flat heat pipe and manufacturing process, can solve the problems of poor boiling heat transfer performance, insufficient capillary force, and uneven arrangement of equidistant grooves, etc., and achieve excellent boiling enhancement performance, capillary Enhanced effect and simple technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

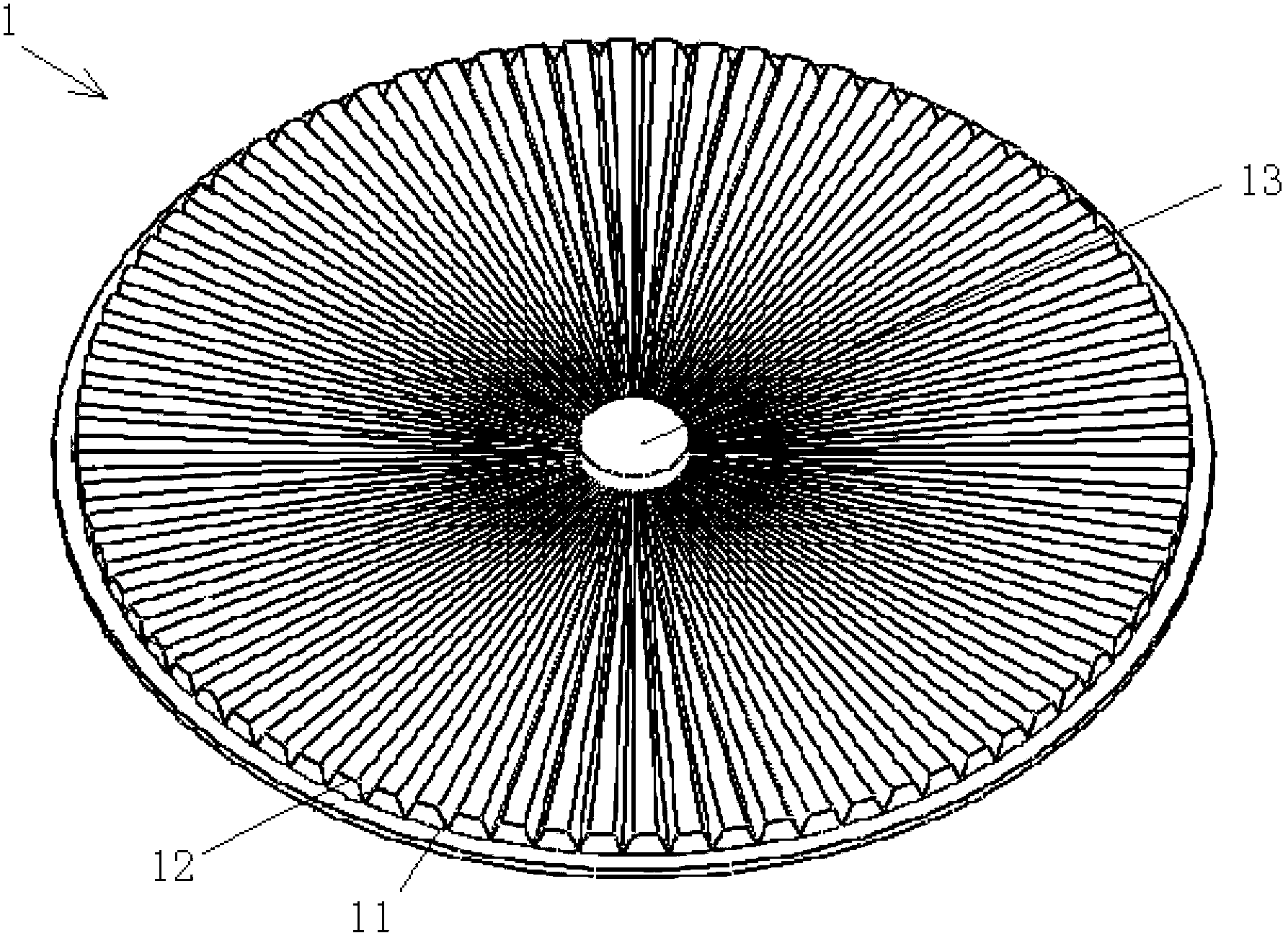

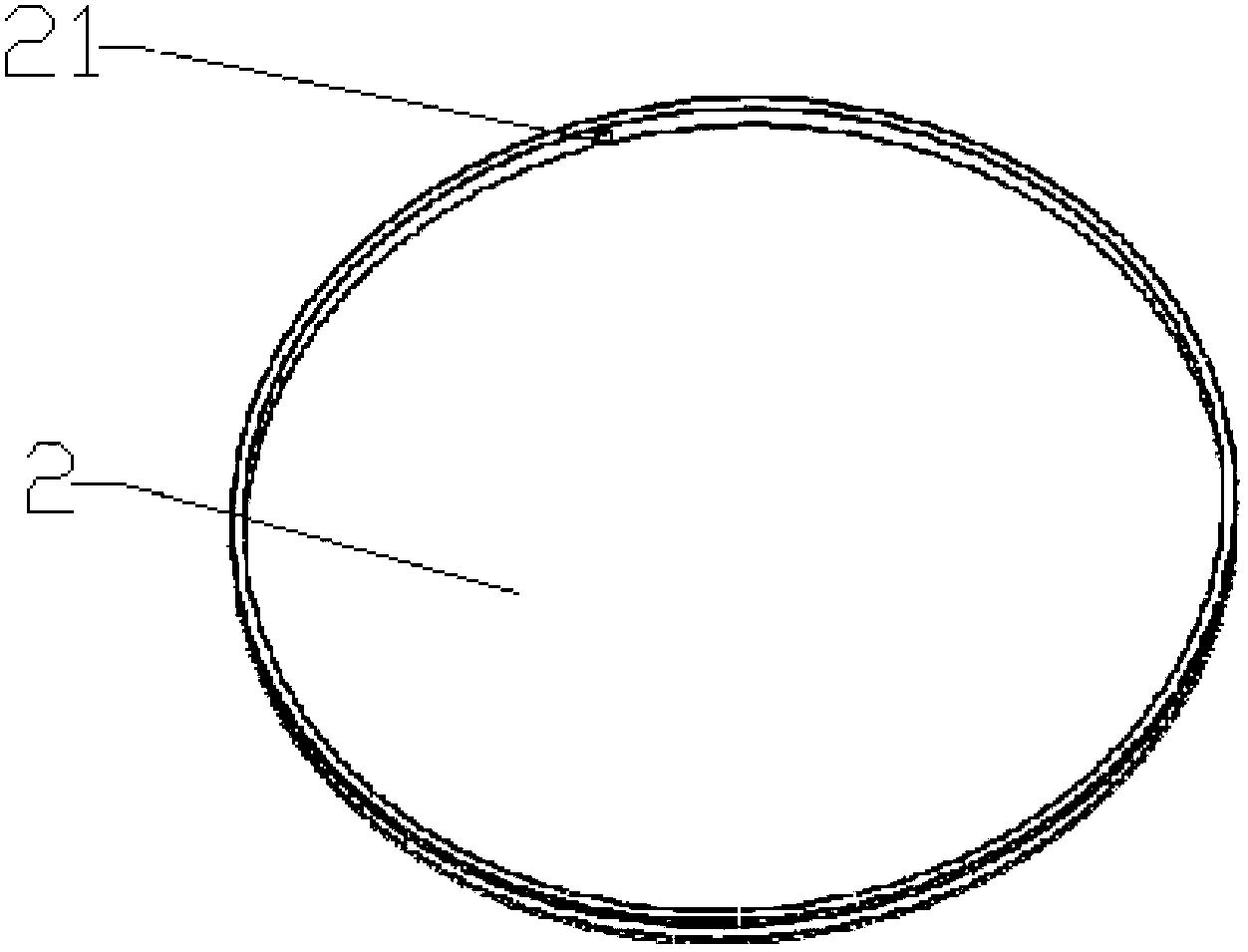

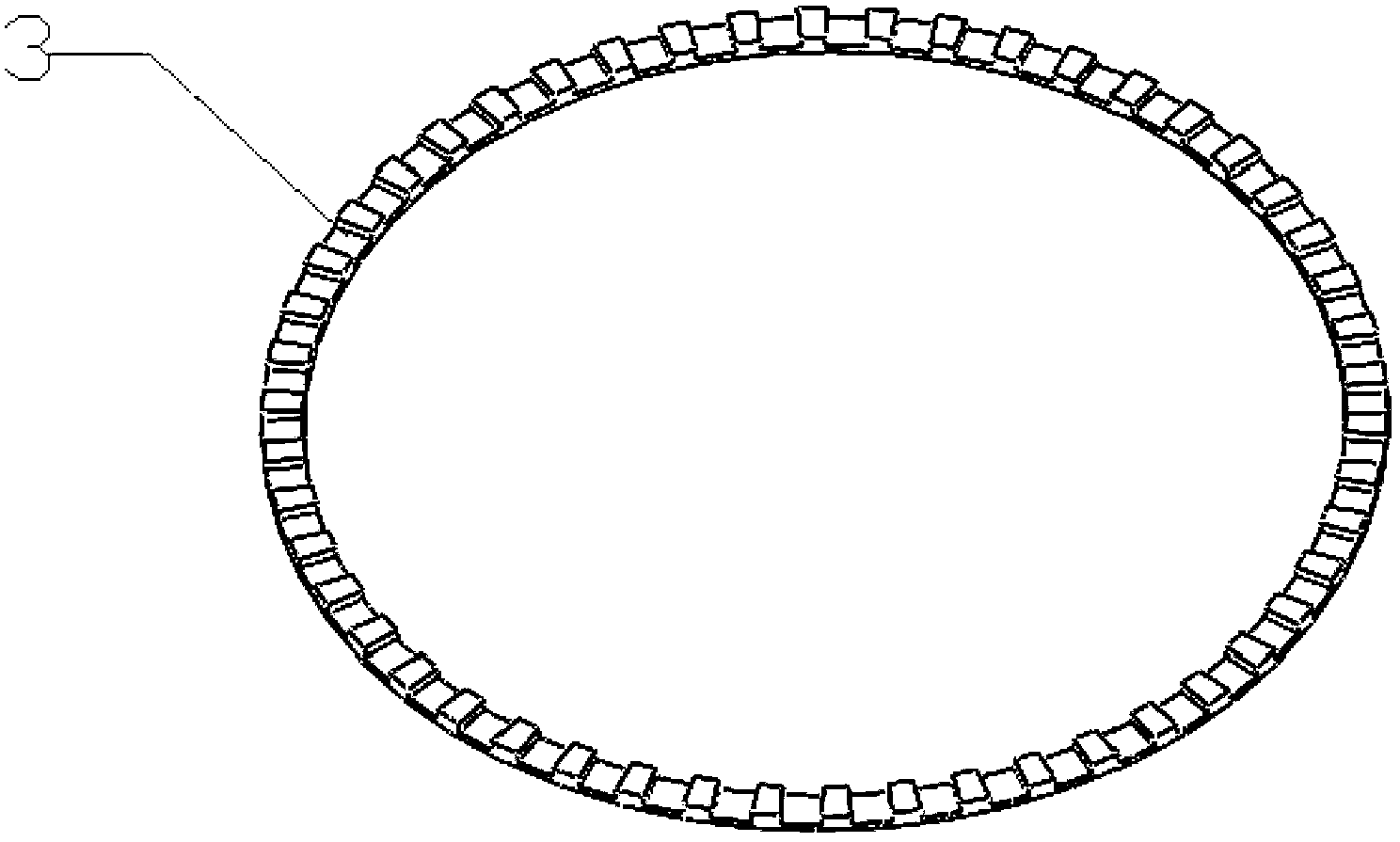

[0033] like figure 1 , 2 , 3, 4, 5a, and 5b, the flat plate heat pipe with radially widened fin structure of the present invention includes a lower base 1, an upper cover plate 2, and a support ring 3, and the surroundings of the lower base 1 and the upper cover plate 2 Sealed connection, the lower base 1 includes a circular base 1-1 with a circular boss 1-2 on the circular base 1-1, the top surface of the circular boss 1-2 is low in the middle and the outer edge The slope 51 of the tall inner conical structure, the top surface of the circular boss 1-2 is radially distributed with V-shaped grooves 11 and ridges 12 from the center outward, and the support ring 3 is placed on the circular boss. The middle part of the top surface of the platform 1-2; the side of the support ring 3 in contact with the ridge 12 is a plane, and the surface of the support ring 3 in contact with the upper cover plate 2 is a concave-convex contact surface; the top of the circular boss 1-2 A capillary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap