Simulation test device for pneumatic load of vehicle body

An aerodynamic load and simulation test technology, applied in the field of car body aerodynamic load simulation test, can solve the problems of high airtightness of the tank body, great difficulty in processing, high processing cost, etc., and achieve low cost, short cycle, and test convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

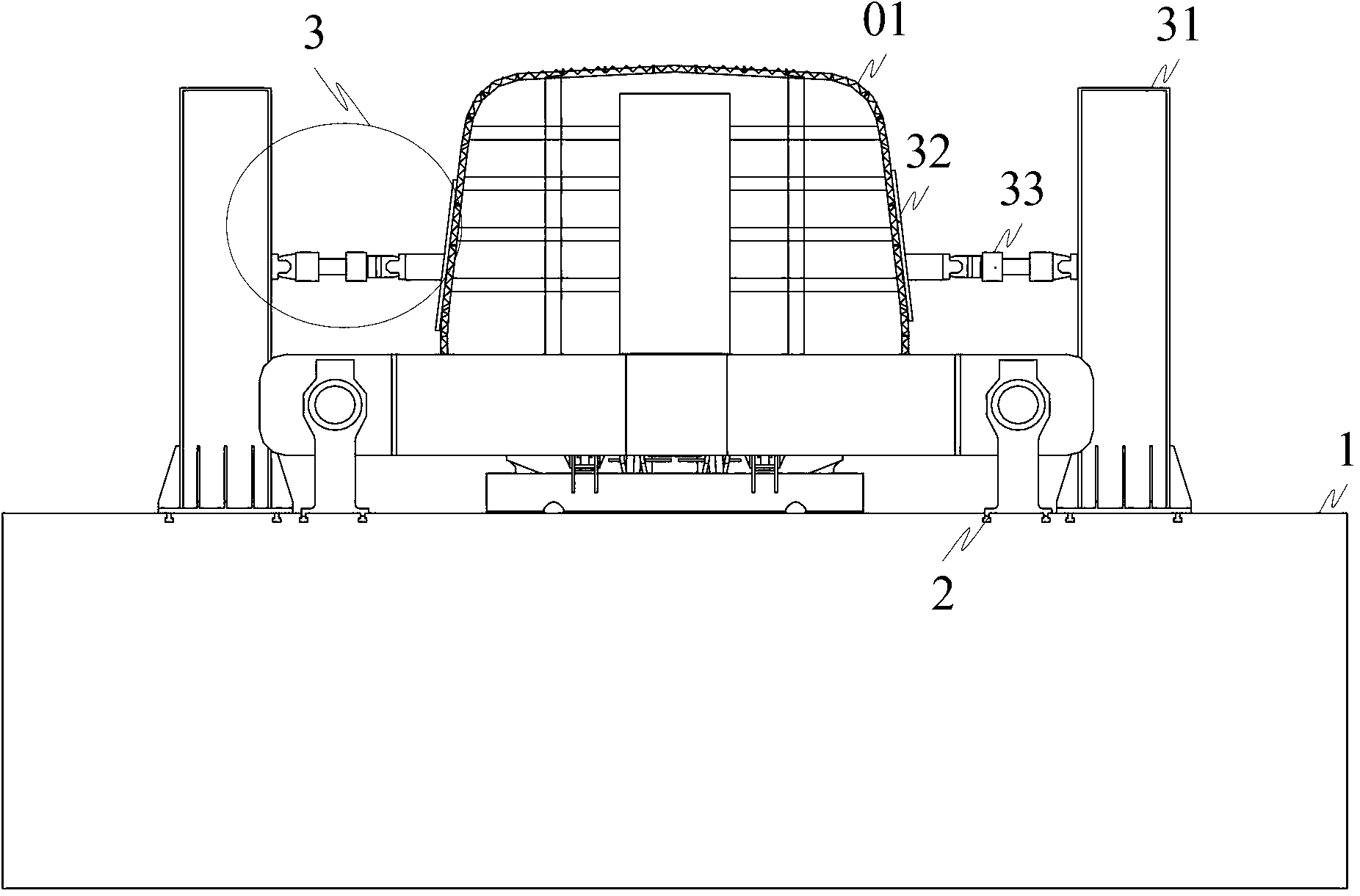

[0011] Such as figure 1 As shown, the car body aerodynamic load simulation test device provided by the present invention consists of a test bench 1, a fixing mechanism 2 for fixing the two ends of the car body 01 to be tested on the test bench, and a fixing mechanism 2 for fixing the two ends of the car body to be tested. The horizontal pressing mechanism 3 for applying pressure is composed of; wherein, the horizontal pressing mechanism 3 is composed of a plurality of pressing components, and the pressing component is composed of a column 31, a wind pressure plate 32 and a hydraulic actuator 33, and the bottom of the column 31 is fixed on the test bench 1, one end of the hydraulic actuator 33 is hinged to the column 31, and the other end is hinged to one side of the air pressure plate 32; the other side of the air pressure plate 32 is connected to the side wall of the vehicle body 01 to be tested. The hydraulic actuator 33 can be directly purchased in the market, and the hinge...

Embodiment 2

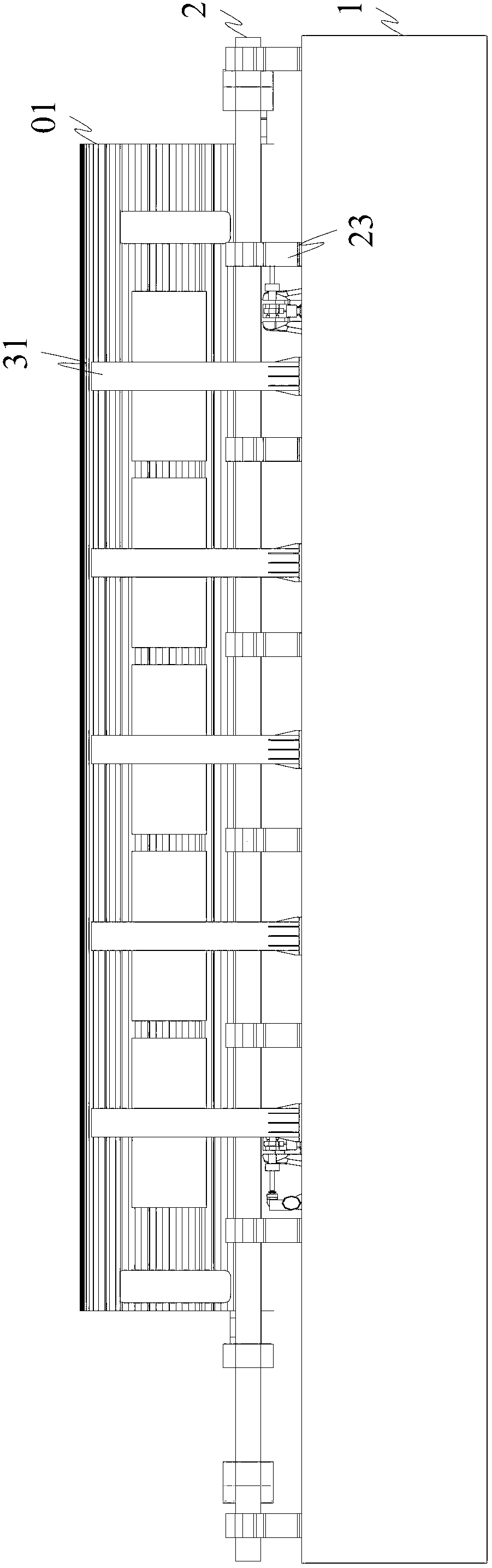

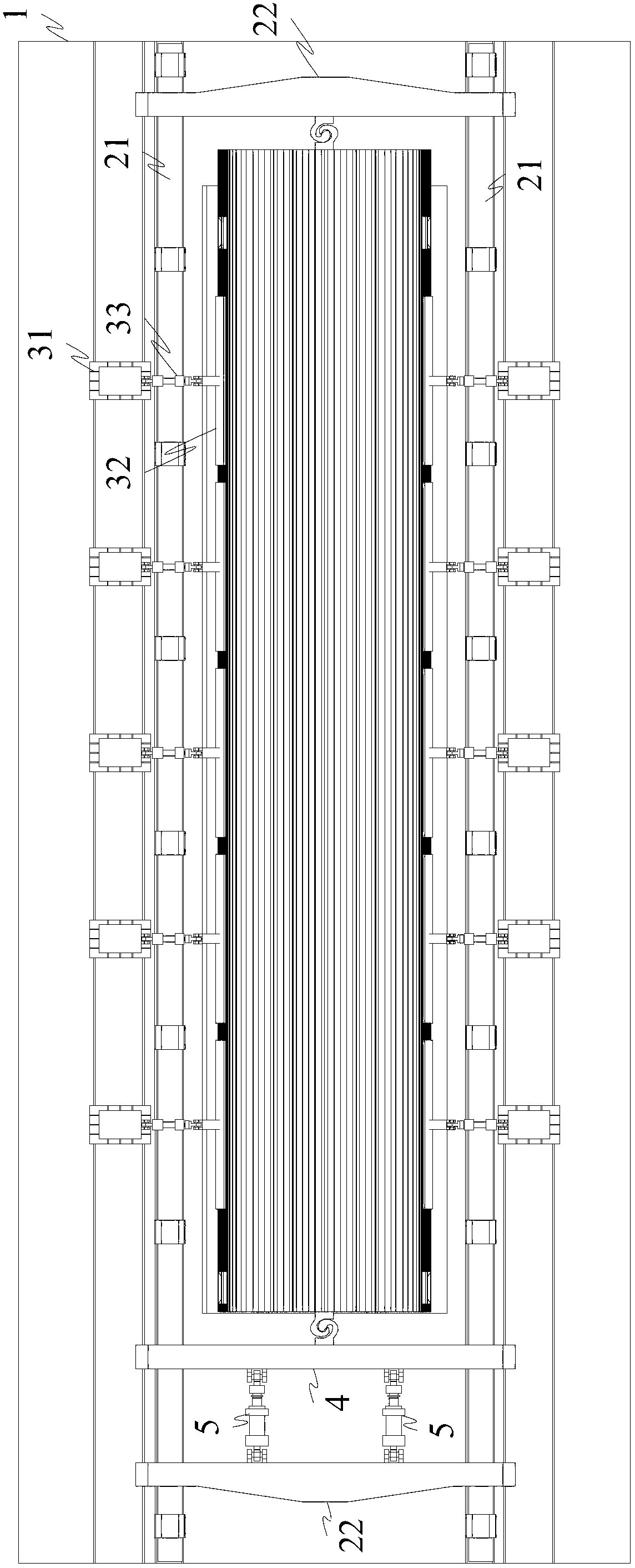

[0016] Such as figure 2 , image 3 As shown, on the basis of Embodiment 1, the above-mentioned test device also has a longitudinal pressing mechanism, and the fixing mechanism 2 specifically adopts a closed ring beam, and the closed ring beam is composed of two longitudinal beams 21 arranged in parallel and two parallel arranged with The reaction beams 22 intersected by the longitudinal beams 21 are enclosed in a closed frame shape. The longitudinal pressing mechanism is specifically a loading beam 4 whose two ends are slidingly connected to the two longitudinal beams respectively. The loading beam 4 and the reaction beam at its proximal end 22 is connected with hydraulic actuator 5. Specifically, the longitudinal beam 21 is fixed on the test bench 1 through a plurality of support seats 23 , and the two ends of the reaction beam 22 are fixedly connected to the two longitudinal beams 21 through fasteners. The hydraulic actuator 5 acts to push or stretch the loading beam 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com