Method for manufacturing dustproof photography module and dustproof photography module device

A camera module, dust-proof technology, applied in installation, image communication, camera body and other directions, can solve the problem of the impact of shooting effect, the short distance of dust from the imaging surface of the chip, etc. Poor dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

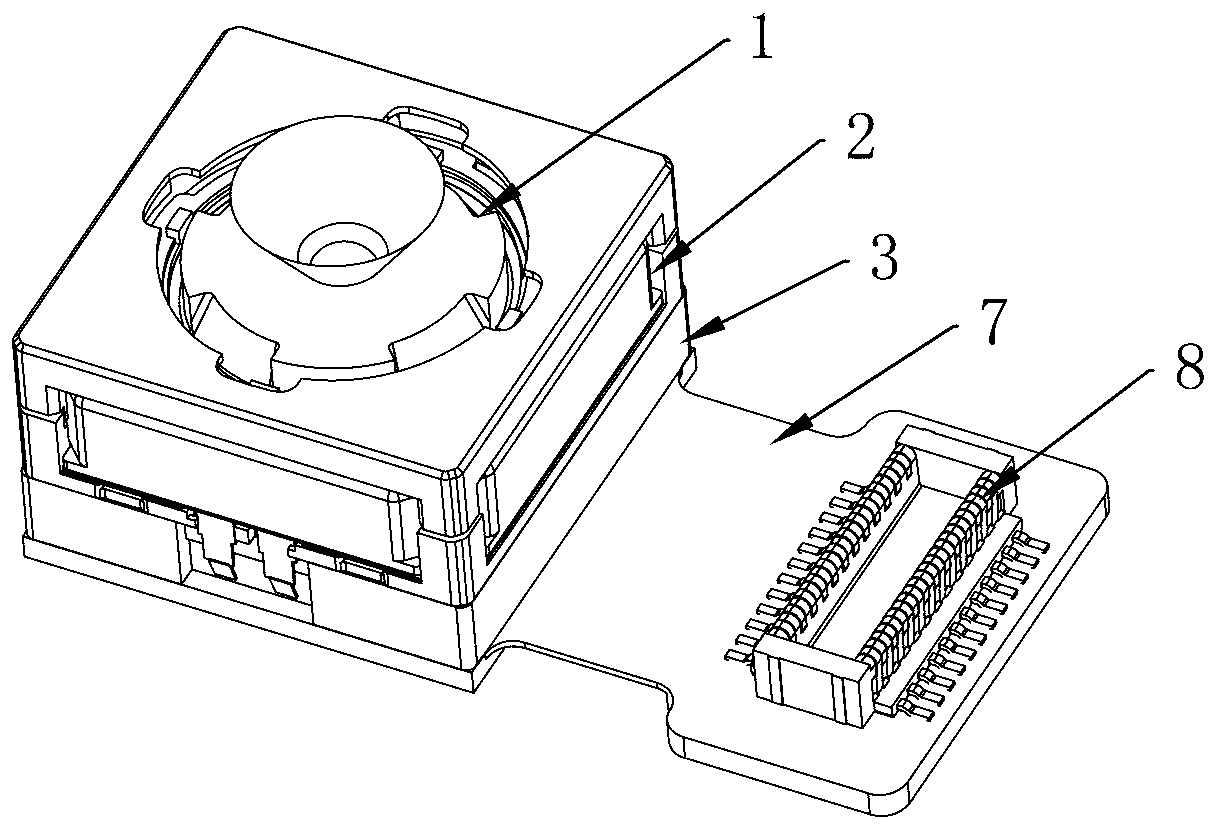

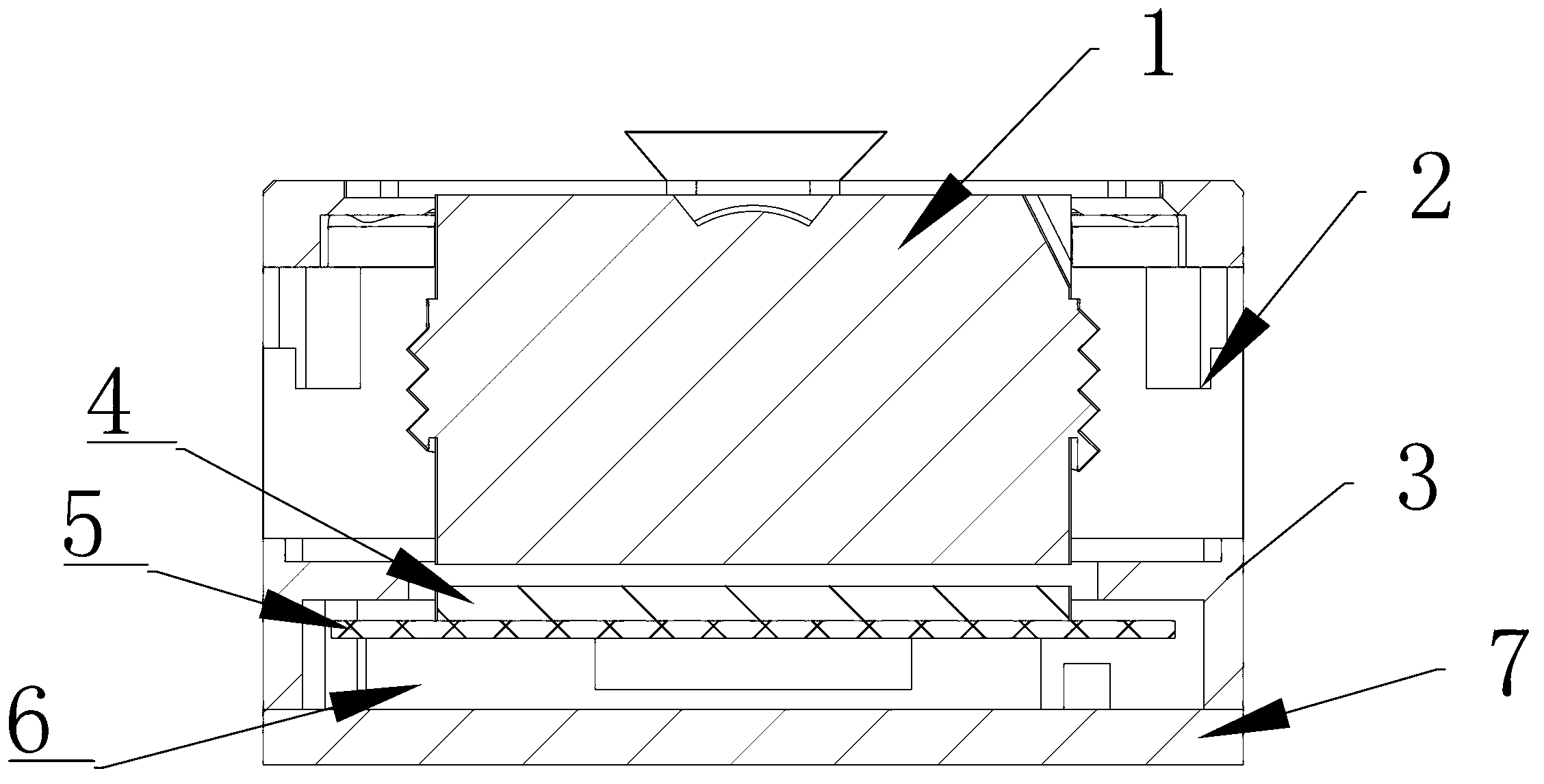

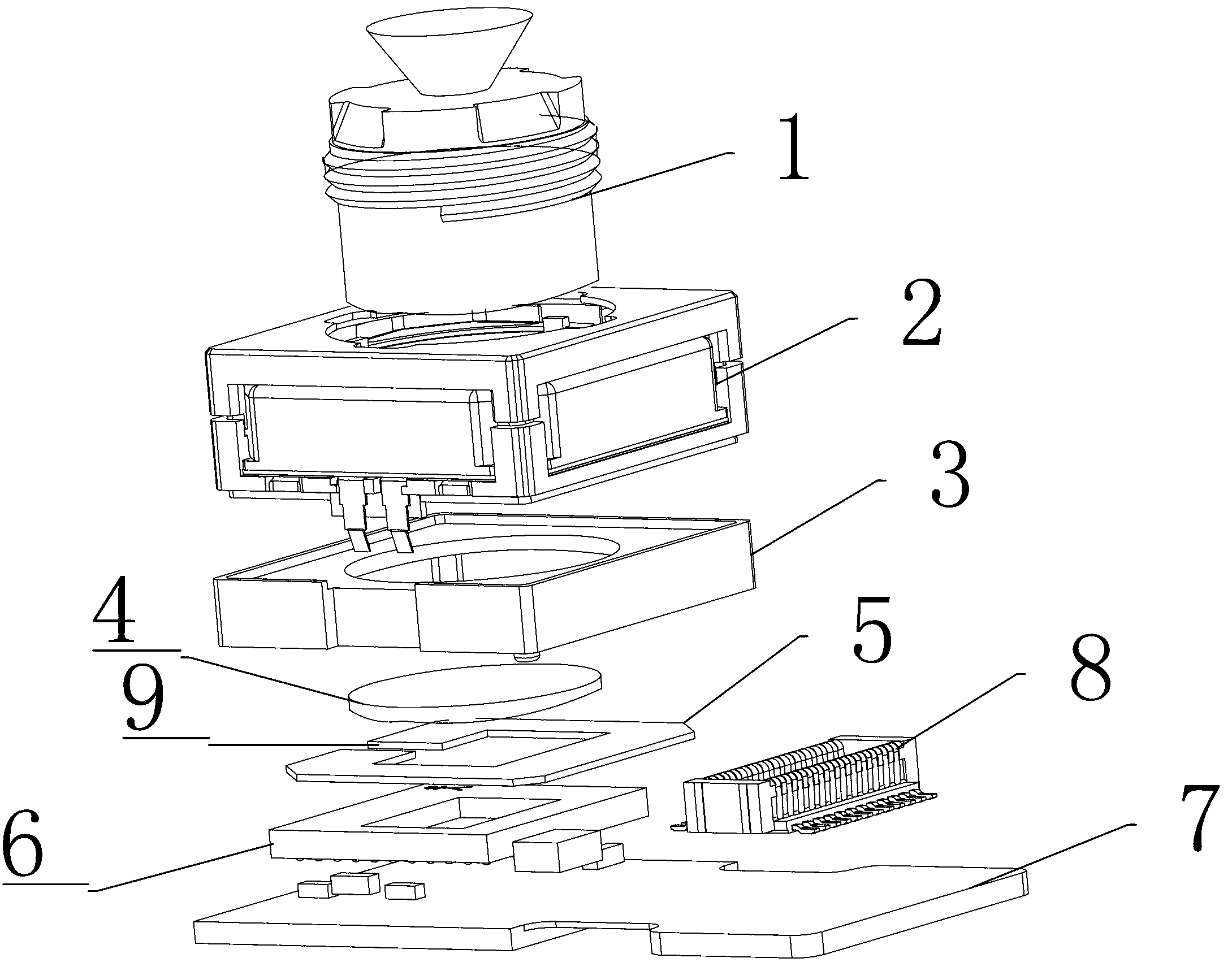

[0032] Example: see Figure 1 to Figure 3 , the present embodiment provides a method for preparing a dust-proof camera module, which includes the following steps:

[0033] (1) Prepare a lens 1, a photosensitive chip 6, and a planar printed circuit substrate 7; set the lower surface of the photosensitive chip 6 on the planar printed circuit substrate 7;

[0034] (2) Prepare a hollow sealing layer with a thickness, arrange it on the upper surface of the photosensitive chip 6 and cover the outer peripheral part of the upper surface, wherein the hollow part is correspondingly arranged directly above the photosensitive area of the photosensitive chip 6;

[0035] (3) Prepare a light-transmitting protective layer of transparent material with a thickness, and arrange it on the upper surface of the sealing layer, and completely cover the sealing layer, directly above the photosensitive area of the photosensitive chip 6 to Between the upper surface of the light-transmitting protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com