High precision sunward automatic tracking method

A technology of automatic tracking and automatic tracking device, which is applied in the direction of control using feedback, can solve problems such as low measurement accuracy, and achieve the effects of high system measurement accuracy, overcoming poor tracking accuracy, and overcoming poor control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

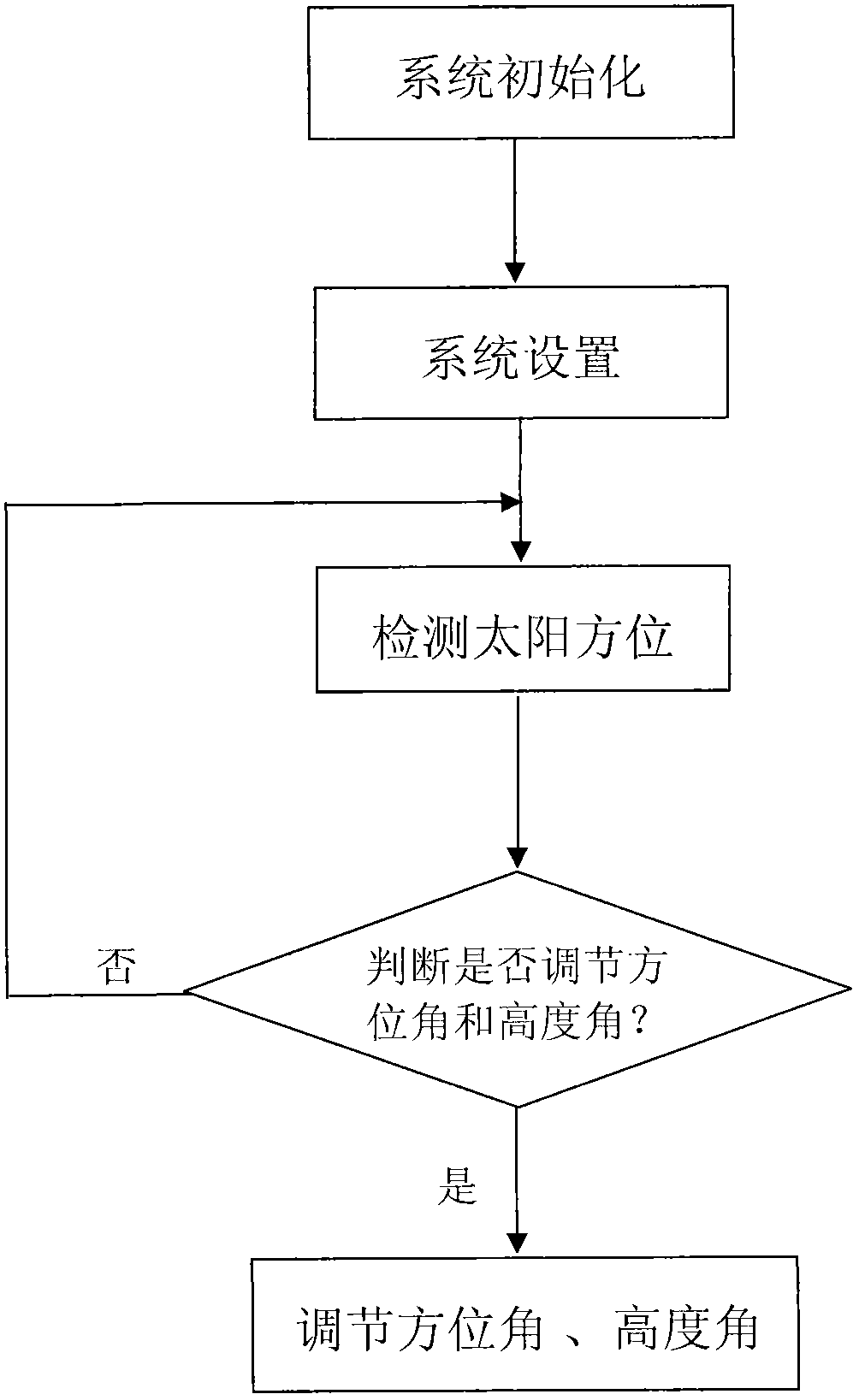

[0035] Attached below figure 1 , To further describe the software process of the present invention.

[0036] Step 1, system initialization

[0037] Before the system works normally, each device must be initialized, including: system clock initialization, port initialization, liquid crystal display initialization, serial port initialization, analog / data control register initialization, real clock initialization, and timer initialization.

[0038] The system clock selects the external clock as the reference, the size of the external crystal oscillator is 11.0592MHZ; when the port is initialized, set the input and output mode of the lO port, turn on the cross switch and weak pull-up resistor inside the central processing unit, and set P1, P2, P3, P5- P7 port is output, P4 port is input and it is open-drain mode, configuration external memory interface, external memory timing control.

[0039] The LCD is initialized, and the connection mode of the pins of the LCD and the central processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com