Constant pressing device for drying transformer windings

A transformer winding and constant voltage device technology, applied in coil manufacturing, etc., can solve problems such as expensive, time-consuming and laborious, and complex equipment structure, and achieve the effects of simple and convenient clamping operation, low device cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

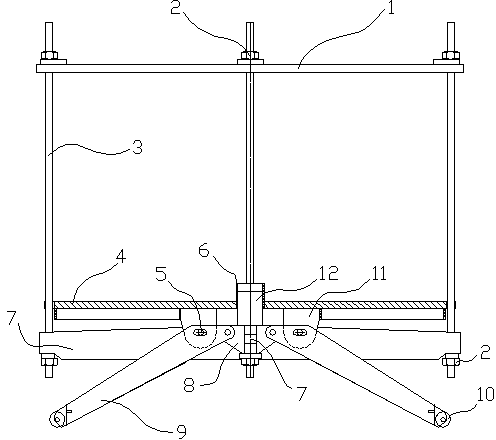

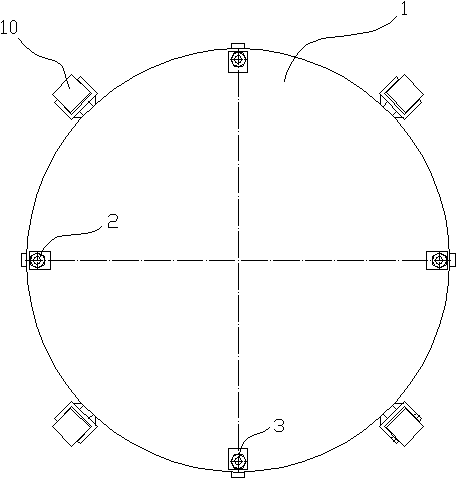

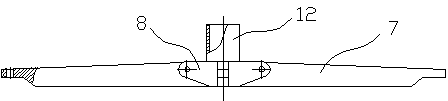

[0020] Such as Figure 1 to Figure 8 As shown, the transformer winding drying constant voltage device includes an upper pressure plate 1, a lower pressure plate 4, four pull rods 3, a force transmission frame 7 and four legs 9, and the upper and lower pressure plates 1 and 4 are circular discs body, the force transmission frame 7 is a cross, and four first hinged plates 8 arranged in a cross are welded at the center of the force transmission frame 7, and the four first hinge plates 8 are located in the plane where the force transmission frame 7 is located. Power frame 7 becomes 45 ° of angles. The outer end of the tripod 9 is equipped with a roller 10, and its inner end is hinged with the force transmission frame 7 through the first hinge plate 8, so that the tripod 9 is evenly arranged on the force transmission frame 7. Four second hinged plates 11 are welded on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com