Bogie stop block

A technology of stop blocks and bogies, applied in wheeled and other directions, can solve problems such as damage to stop gaskets, damage to bogie beams or landing gear struts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

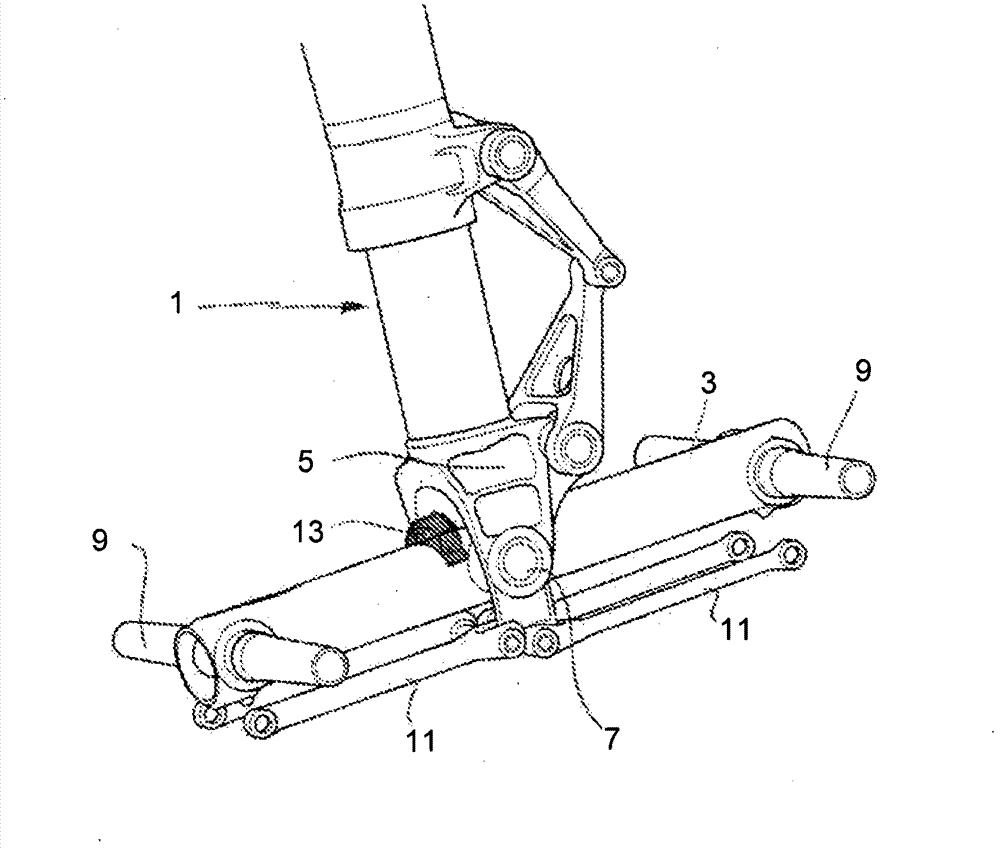

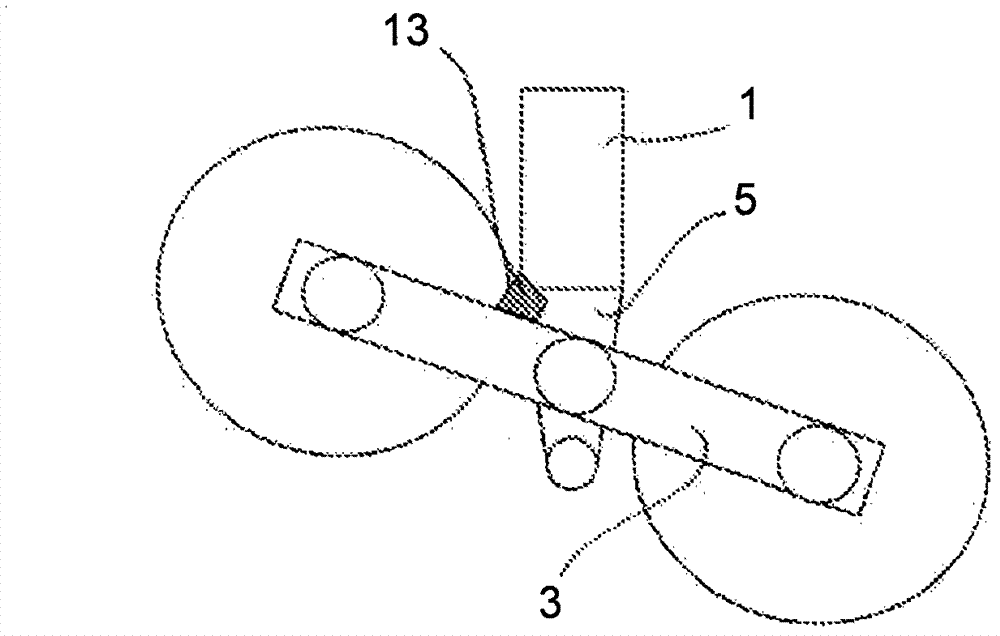

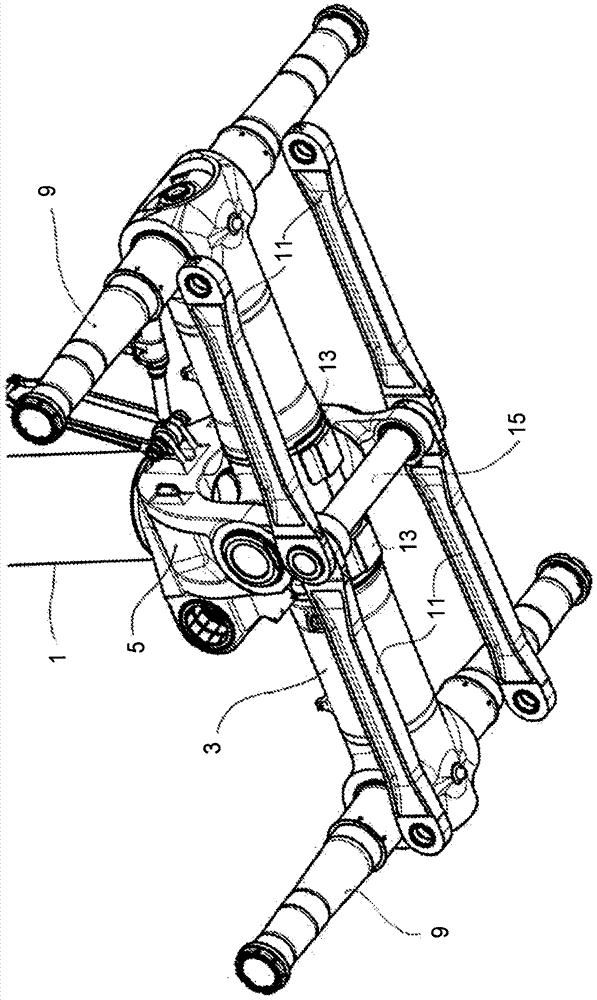

[0027] Referring to FIG. 1 , there is schematically shown an aircraft landing gear assembly known in the prior art. The landing gear comprises a shock strut 1 for aircraft landing gear arranged to be connected to the aircraft at a first upper end and operated in a conventional manner to be stowed or deployed. At the second lower end of the damping strut 1 , the strut is pivotally connected to the bogie beam 3 . A typical arrangement of the lower end of the damping strut 1 includes a fork yoke 5 extending either side and below the bogie beam 3 . A pivot pin 7 pivotally connects the bogie beam 3 to the yoke 5 . The bogie beam usually comprises two or more axles 9 to which the solid aircraft wheels are fixed. Additionally, it is also common practice to provide one or more elongated brake rods 11 extending between the lower extremity of the strut yoke 5 and the brake assembly associated with each aircraft wheel (not shown). Each brake lever 11 is typically pivotally connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com