Permanent magnet coupling

A permanent magnet coupler and permanent magnet technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electrical components, etc., can solve the problems of high manufacturing cost and high cost, and achieve low manufacturing cost and no material loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

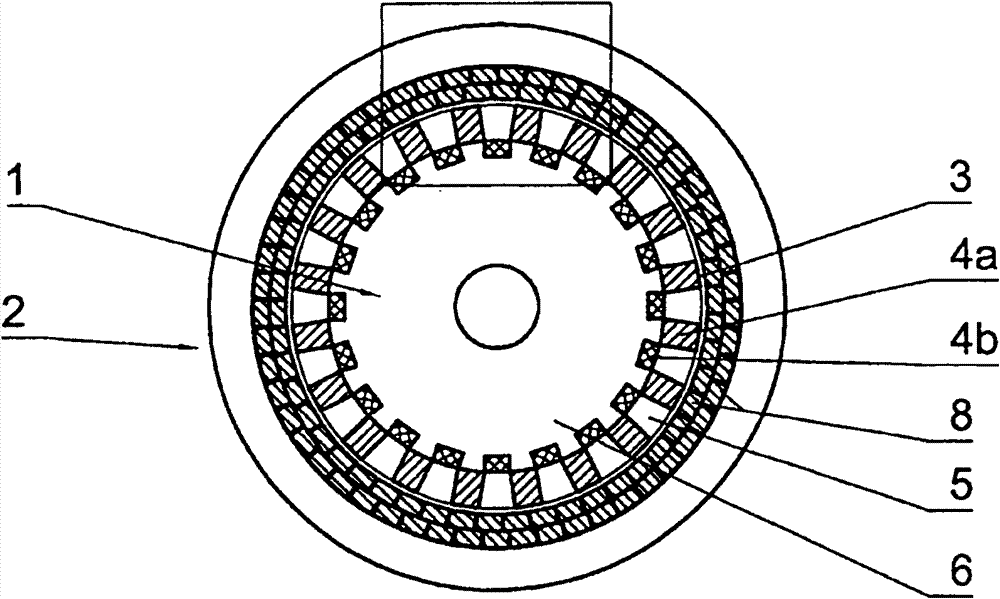

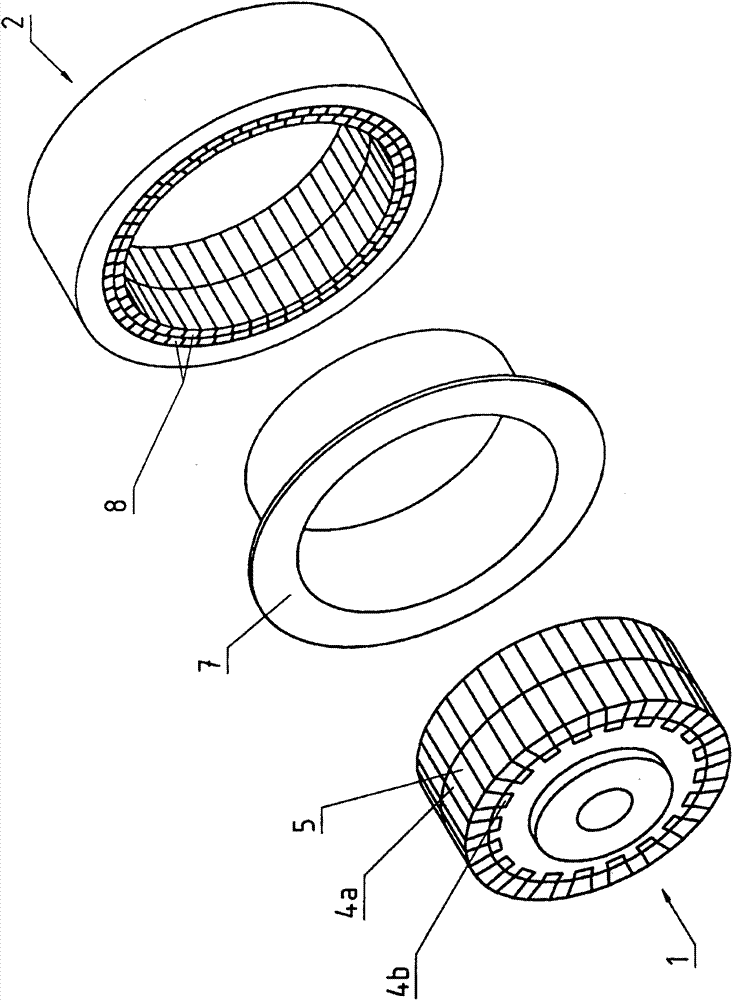

[0023] figure 1 A permanent magnetic coupling for torque transmission is shown with a first component 1 configured as an inner rotor and a second component 2 configured as an outer rotor, which are separated by an air gap 3 . The first component 1 has a first set of permanent magnets 4a and a second set of permanent magnets 4b arranged between these permanent magnets 4a.

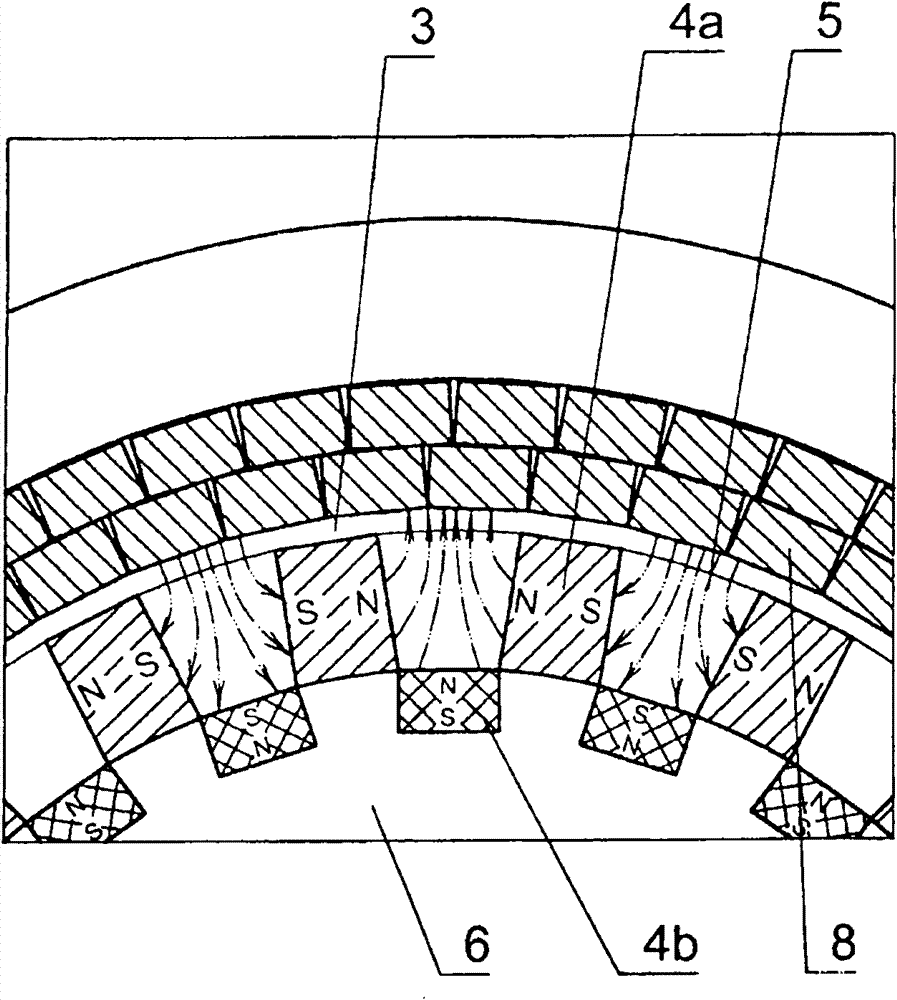

[0024] exist figure 2 It can be seen from the detailed view that the magnetization direction of the first group of permanent magnets 4a is oriented parallel to each adjacent air gap 3 in the circumferential direction, and the permanent magnets 4a of the first group arranged successively in the circumferential direction have alternately opposite the magnetization direction.

[0025] Starting from the air gap 3, the second group of permanent magnets 4b is staggered backward relative to the first group of permanent magnets 4a, so that the gap 5 without permanent magnets is reserved between the air gap 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com